Another in a series of previews to Sensors Converge 2023

Trepidations over electric vehicle (EV) battery life have fueled range anxiety, but could the ever-increasing amount of in-vehicle computing put undue pressure on automotive power?

EV or not, autonomous or not, there’s no doubt that today’s car has a lot more electronics content in it. Thanks to the ubiquity of smartphones, drivers are transferring their user expectations to dashboards and infotainment systems. And while the modern vehicle is increasingly being compared with a server on wheels – even a data center – the workloads being done in a car are more like that of a tablet.

And like any tablet, touch screens, memory and storage, and networking all contribute to a car’s power consumption. The obvious solution to reducing power consumption would seem to be that each device should be more efficient, which combined can yield dramatic reductions.

But other trends in automotive design can aid in getting a handle on computing power consumption, including a move to more consolidated architectures as well as switching losses during power conversion so that devices can get the power necessary to meet performance expectations. Reduction isn’t always the goal – optimization is.

Solutions for reducing power consumption need not be developed from scratch, either. Just as automotive computing workloads are similar to personal and enterprise computing use cases, so are the approaches to managing power use.

Drivers want the smartphone experience

The days of dials and switches are long gone. Today’s cars all have sleek digital displays and buttons, if not touchscreens for just about every function on the dashboard. The user experience drivers expect can longer be supported by spinning the dial but with functional surfaces.

“If you just had mechanical knobs, there's not a lot you could do,” said John Brady, senior director of automotive programs at Synaptics. “There's just too much functionality.” Operating the car’s AC or windows is still doable by a knob or a switch, but it’s not possible to use Google maps without a display, he said.

The display doesn’t necessarily have to be a touchscreen, but modern vehicles require large displays for in-vehicle infotainment (IVI) systems because drivers are demanding them, Brady said, and they’ve become accustomed to a dynamic user interface that can be manipulated. That expectation includes the instrument cluster, which is full of rich information like speed and fuel.

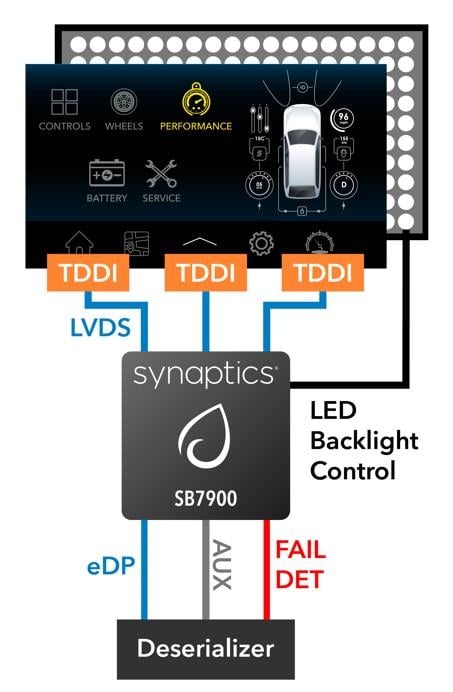

With displays that use liquid crystal display (LCD) technology, the LCD gets polarized and turned on to let through light from a backlight unit – there’s not light coming from the LCD itself. A matrix backlight using light-emitting diodes (LEDs) that can be turned on and off as needed in and enables capabilities like local dimming and contrasting. “You can illuminate a very specific area and not the rest of it,” Brady said.

A matrix backlight is more efficient than an edge lit display, which would require turning as many as 32 LEDs just to light up one little bright spot, he said. By using a matrix backlight, power consumption can be reduced as much as 80%. By using a dark UI for the vehicle display, many of the LEDs can be turned off where there’s no content, Brady said. “You can save significant power.”

Ambient sensors within the vehicle also provide the potential for the displays to be automatically responsive based on the available light coming into the car via windows and sun rooves – this environmental awareness means the displays can adjust to different conditions such as dusk or night. “Nighttime would be a lower power mode,” Brady said.

Capabilities such as local dimming shine a light on how automotive technologies and their power profiles don’t have to be built from scratch. Rather they are informed by other computing paradigms, including smartphones, tablets, televisions, and servers in data centers. “Local dimming has been a concept that's been out there for a long time,” Brady said. The technology being applied in automotive displays is the same that’s been used in LED TVs, which has been become increasingly common.

Given how display-heavy the cockpit of the average car has become, the tablet might be the best parallel when it comes to computing workloads and their power consumption. Sebastien Jean, CTO at Phison Electronics said much like a tablet, the screens in vehicles are touchable and integrated with cameras and sensors to support an adaptable cockpit display. “I would say it's a lot more like a fancy tablet or two tablets depending on how they're set up.”

Architectures guided by enterprise computing

For the SSDs in the car, it’s more of a data center computing paradigm but without the typical enterprise processor, which has an impact on power consumption, Jean said. “Even though it does have vision processing elements, it's not running a high-end graphics card that consumes 800 watts. That's just not the type of hardware that it's running.”

A car’s features do go well beyond what you would find on your laptop or what you would find on your phone, he added. “But from a power consumption standpoint, it's probably more in line with a high-end tablet being used aggressively than it is like a gaming rig.”

Automotive computing architectures are also benefiting from virtualization, which emerged in enterprise computing 20 years ago, Jean said. SSDs in vehicles can be shared with multiple hosts; this consolidation and reduction in complexity allows for economies of scale that enable more efficient power consumption as well as cost reduction because fewer elements to qualify and validate.

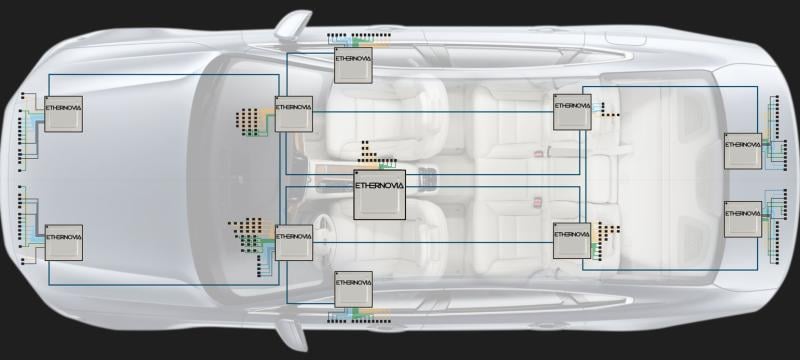

This consolidation is also being enabled through networking, and enterprise technology has come out the winner on that front: ethernet has solidified itself as the in-vehicle connectivity backbone to enable applications and improve performance as the electronic content in cars continues to grow.

In-vehicle networking requirements are being driven by the growing amounts of sensors in the car to support autonomy as well as the necessary compute power, said Chris Mash, vice president of business development at automotive ethernet chip startup Ethernovia.

Another significant trend is cloud connectivity so media can be downloaded to entertain passengers, as well as applications, additional services or features that change the operation of the vehicle, he said. “We have much higher bandwidth and much higher computer resources required to operate the vehicle and run the applications.”

Moving data must be more efficient

But just as virtualization is enabling consolidation of data storage, OEMs are trying to simplify their network with consolidation of ECUs and the network, Mash said. Today’s cars are using what is called a domain architecture, which is a siloed approached where controllers are dedicated to specific features such as chassis control or an infotainment feature.

It’s not very efficient, he said. “Multiple wires going into the same location lends itself to a large number of ECUs, then the associated software and complexity on top of that.”

Mash said the move to EVs has allowed OEMs start with a blank sheet of paper. “That's typically where we see most of the changes to the consolidated architectures coming with central compute and zone aggregation.” He said Ethernovia’s technology is enabling the network architecture changes by consolidating today’s numerous simple domain ECUs into a small number of higher performance multi-domain ECUs while also addressing the increased bandwidth demands and software defined services.

By reducing the number of wires, Mash said Ethernovia is also addressing the number of physical transceivers in the car, which is one methodology for reducing power consumption. “We're reducing the number of transceivers required because we're now moving to a higher speed ethernet backbone that can sustain significant data for multiple networks with a single cable.” He said it also reduces the weight, which has a positive impact on overall power use.

One of the most significant drains on power is data movement, Mash said, and Ethernovia’s approach provides an optimized and efficient way of moving data from the network into the compute resources. This allows OEMs to add features but reduce complexity and save power. He said fewer connections mean fewer watts consumed. “For EVs, every watt matters significantly more.”

Companies like Macronix, which serve the automotive segment, are contributing to the power reduction in vehicles through its low-power flash memory that's designed into automotive-processor-based compute systems. The company’s OctaFlash draws as little as 1.7V and is “on call” for systems’ high-performance demands – it operates at 400Mbps – but quickly goes back to deep-sleep mode.

Infineon Technologies is focused on driving power efficiency as part of the EV supply chain, not only within the vehicle but by working with the entire ecosystem such as renewable energy companies supporting the charging infrastructure.

Bill Stewart, VP of Automotive Marketing Americas at Infineon Technologies, said that even with the power consumption concerns, EVs are still significantly more efficient than gas internal combustion engines, and their carbon footprint on the road is quite small.

As much as the various compute, networking and data storage components contribute to the power profile of a vehicle, there’s a price for converting power, which is why wide bandgap technologies like silicon carbide (Si) and gallium nitride (GaN) are getting so much attention. “Every time you convert the power, you have a switching loss,” Stewart said.

Optimization matters as much as reduction

Central compute and consolidated architectures can help reduce the number of times power conversion is necessary, but so can moving away from mechanical systems that rely on friction, such as braking, Stewart said. “You basically convert all that energy to heat.”

With EVs, there’s a move toward electronic systems that control brakes that will enable the recapturing of energy that can be returned to the battery, he said. “Before you were powering a pump that was then wasting a lot of energy that was ultimately lost to heat. Now you're powering electronics that are being used to recapture energy.”

Ultimately, reducing the power consumption of each component and system isn’t the only way to optimize energy efficiency within the vehicle. Stewart said if you have fewer ECUs, then those ECUs may be able to consume more power while still achieving a net decrease.

Rather than always focusing on smaller geometry devices to address power consumption, Infineon looks at how its power and sensor devices can be made more efficient at larger geometries to reduce switching losses, Stewart said.

Sometimes it makes sense for a sensor to draw more power to provide better resolution, but the overall system can still draw less power because switching losses have been reduced, he said. “It's not necessarily that the chips do more or less power consumption, but how are they enabling the system to use less power consumption? That's really how we try to look at it.”

Editor’s Note: Some of the vendors included in this article will exhibit at Sensors Converge 2023 in Santa Clara, California, June 21-22. Infineon Technologies will be at booth 762, while Synaptics will be at booth 822. Infineon’s senior director of sensor systems, Amritraj Kahttoi, speaks on Xensiv Sensors at 1:20 p.m. PT June 21 and Preet Sibra, svp of power and sensor systems, speaks on a panel at 8:30 a.m. June 21, among others from Infineon appearing at the event.

Check online for a full list of exhibitors and conference programs, and to register for the event.