Smart surfaces have become ubiquitous, whether it’s touchscreens on smartphones and kiosks or buttons on appliances and car dashboards, but there’s still room for innovation, both in the manufacturing process and the potential applications.

It’s important to differentiate between them – there’s a difference between a capacitive touchscreen that has a conventional circuit board behind the surface and functional surface that has embedded technology within. For many of the emerging applications, all that’s needed is a functional surface, with its appeal not only coming from its futuristic look but also its lighter weight, which is a valuable trait especially for automotive use cases.

Lightweight and low-cost appealing for many appliances

While touchscreen technology is quite mature, there is room for improvement when it comes to functional surfaces such as those used for kitchen appliances, automotive interiors, medical devices, or even furniture, according to a recent IDTechEX report, “In-Mold Electronics 2023-2033.”

In-mold electronics (IME) offer a simpler and more sustainable approach to producing functional surfaces, according to the report. And compared with conventional mechanical switches, IME reduces weight and material consumption by up to 70% while using far fewer parts – lightweight functional surfaces in cars make them lighter and reduce the energy needed to move them.

Matthew Dyson, principal technology analyst at IDTechEx specializing in printed/organic/flexible/hybrid electronics, told Fierce Electronics in an interview that typical functional surfaces don’t involve a digital display, so they’re much cheaper than a touchscreen that is essentially capacitive touch on a display. “You are not able to have something that is dynamic to the same extent. If it's a coffee machine, how many buttons do you need?” He said this kind of human machine interface can potentially be integrated with anything, including a kitchen cabinet or the armrest of a sofa. “It doesn't have to be somewhere where you necessarily want a display.”

Like capacitive touch on touchscreens, some of the technologies in functional surfaces such as membrane switches can be described as “old.” What’s new, said Dyson, are the ways of integrating that functionality so they can be incorporated into curved and more decorative surfaces with some backlighting. These new applications requiring such decisions to be made, he said, include whether buttons need to be pressure sensitive – with a touchscreen on your phone, you’re either touching it or you’re not.

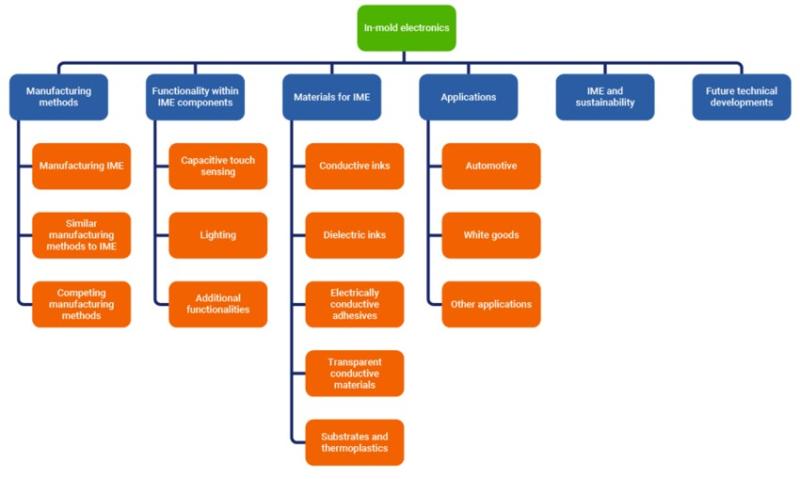

Emerging applications with new form factors are driving changes to how these technologies are manufactured. As outlined in the IDTechEx report authored by Dyson, manufacturing methods for in-mold electronics can accommodate surfaces with and without integrated surface mount device (SMD) components such as LEDs. Functional film bonding and direct printing producing similar decorative touch-sensitive interfaces are among the methodologies evaluated.

The report also looks at the various materials for IME, including conductive and dielectric inks, electrically conductive adhesives, transparent conductors, substrates, and thermoplastics. Dyson said one of the challenges making more integrated functional surfaces that are lightweight is they are harder to separate, which means they are more difficult to recycle at the end of their lifespan.

Overcoming form factor constraints is the next frontier

The next stage for touchscreens and functional surfaces is looking at how capacitive touch can be built into thermoformed shaped plastic, Dyson said, which would allow for slider-style controls that you wouldn’t see on your typical microwave but would find in your modern vehicle by using in-mold electronics with embedded chips. At the same time, he said, the aim is to see if functional surfaces can be lighter and made more cheaply while overcoming some of the form factor constraints. “What they're doing is basically embedding the functionality into the surface rather than mounting it behind the surface.”

Dyson said a big area of interest is the automotive sector because all the car makers now want to make their interiors look more expensive. “This is a way of making the interiors look more luxurious without actually spending any more money.”

Taifang Technology in Beijing is one company that’s looking to innovate with automotive surfaces – but not just for fancy, functional interiors. The second-generation of the Taifang Automobile Intelligent Perception System (TAIPs) also has applications outside the car to make it smarter, safer, and more secure.

What’s unique about Taifang is its ASIC, said Bob Yang, the company’s executive director for business development, in an interview with Fierce Electronics. TAIPs uses a unique formula material sensor and an advanced algorithm to capture highly accurate data from touch sensors throughout a vehicle’s “skin.” He said the latest iteration, TAIPS 2.0, has improved upon the sensor and algorithm to a point where it’s now able to sense and report on collisions as low as one kilometer per hour, which fills a gap in the automotive industry for low-speed crashes.

The sensors are only millimeters in size working with a controller and intelligent, elastic wave-based algorithms, Yang said. “We can sense the wave form of vibrations.” The information gathered is turned into a dataset to be run through Taifang’s ASIC. The system uses a combination of high-and low-pressure molding technology, which reduces sensing-system costs. One scenario for sensitive skin on cars is that it could detect minor bumps and scratches on rental cars, which would reduce the need for manual inspection by either the driver or car rental company.

What makes the company’s technology notable is that unlike other force-touch products on the market, Taifang’s technology can be used with any solid surface, including metal, glass, wood, plastic, and composites, as long as it’s a hard surface, although the surface can be curved. “The design itself is very simple,” Yang said. It’s also lightweight and sensitivity can be adjusted depending on the application; other uses include laptop trackpads – Lenovo has implemented Taifang’s technology and invested in the company.

While Taifang’ technology has applications for touchscreens, that market is somewhat saturated, and the greater opportunity for the company is computers and automotive, Yang said. One thing Taifang does that’s applicable to where touchscreens are headed is the ability to work with gloved hands. Along with condensation or dirt on the screen, gloved hands are one of the last barriers to touchscreen accuracy.

Software, AI could make touchscreens smarter

The digital touchscreens that were made widespread by Apple with the first iPhone are everywhere now. Aside from smartphones and tablets, they’re used in a wide range of kiosks and self-checkout machines. OneScreen Solutions has been in what it calls the interactive flat panel business for a decade now with a strong focus on education as well as government and healthcare.

In an interview with Fierce Electronics, OneScreen senior product manager Farhan Qazi said large touch screens pushing close to 100 inches in display size are replacing multiple technologies in the classroom, including projectors and conferencing systems – a conference room may have one large single screen with wireless connectivity and microphones running a familiar operating system such as Android or Windows. He said the education sector is the “bread and butter” for these devices, replacing whiteboards. “All these interactive flat panels provide very superior touch capabilities. The feeling when you write on these is as natural as it can be on your glass boards or on your basically standard whiteboards.”

The natural feel has improved significantly in the past five years, said Qazi, and it’s a function of the latency, the number of touchpoints that are supported and the number of gestures that can be performed – most interactive flat panels in the classroom are supporting less than eight milliseconds. He said software plays a critical role in delivering this user experience.

Today’s touchscreens no longer need to be calibrated to maintain the touch accuracy, Qazi said. OneScreen employs zero bonding touch technology, which enables its flat panels to deliver the same accurate touch experience users have come to expect from their smartphone.

Because touchscreen technology is so mature, he said, innovation is being driven more by software and artificial intelligence (AI) than hardware alone, which will still make advances in latency and speed to contribute to a natural feeling of writing, using multiple fingers to perform a gesture, or even emulating an erase feature by swiping of the palm, just like a chalkboard. Qazi said AI will allow for features such as the ability to recognize a person’s handwriting. “Overall, the touch screen experience is driven by the combination of hardware and software.”

Aside from AI, the Metaverse could present new opportunities for touchscreen – it’s possible that virtual reality (VR) and augmented reality (AR) could interact through gestures with an interactive panel but with the bulk of the experience being in a VR bubble, Qazi said. VR/AR has yet to produce anything that connects the touchscreen so far and AI is showing up through software applications, he said. “There are different directions in which this technology can take. It's evolving.”

Broadly speaking, the innovation appears to be in functional surfaces with automotive ahead of the pack when it comes to market growth, IDTechEx’s Dyson said. “There's also opportunities in aerospace, but when compared to cars, there aren't that many planes.” Functional surfaces also have applications in medical devices and smart locks, he said, but the main market is automotive where the novelty is being able to wrap it around the curves of car consoles and embed functionality.

For a touchscreen to have that capability would require some innovative engineering. “Folding screens, stretchable screens or screens that can bend along more than one axis of curvature are a long way off,” Dyson said.