The evolution of electronics means that sensor-based devices are becoming more digital, smart and connected, impacting all industries, but particularly automotive, consumer goods and industrial equipment. Many of these devices will be built using standard off-the-shelf silicon, however, companies are now increasingly adopting a custom SoC solution to meet the demands for specific application in order to optimize performance, power efficiency whilst lowering cost.

Custom SoC benefits

There are many potential reasons to build a custom SoC:

- Lower the overall product cost, replacing many discrete components with one chip

- Reduce the component count, complexity, and PCB size

- Improve the reliability – a conventional PCB with hundreds of individual components has many points of failure and custom silicon can remove them

- Protect the product, making it harder to reverse engineering and copy

- Reduce the complexity of your supply chain, assuming complete ownership of the chip life cycle, ensuring long life supply

- Make a product more compelling and differentiated by adding new features unavailable in standard products

- Combining digital intelligence with analog sensors to make a device smart

- Meet performance and cost requirements for a specific application or product that are impossible to reach with off-the-shelf components

Building-block IP availability

When building a chip, all the required pieces can be easily purchased from third party vendors or provided by the design services partner.

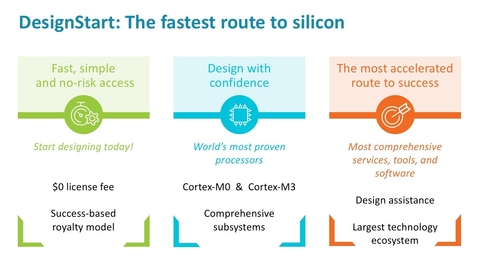

Arm is a major IP provider, and many off-the-shelf devices you’re probably already using are currently based on Arm Cortex processors. To increase success, you can now quickly access the Cortex-M0 and Cortex-M3 processors with a simple click-through EULA with no upfront fee through the Arm DesignStart program. Both of the DesignStart packages also provide a system design kit with a subsystem and a wide range of building blocks. For example with the Cortex-M3 DesignStart, you get the Arm System Design Kit SDK-100, which includes the SSE-050 subsystem and peripherals. The subsystems contain all the common elements needed as a starting point, or simply as a reference design to work from.

Design support – no matter your level of expertise

The implementation phase can be easily outsourced to the many design service companies, such as in the case studies below. These companies provide services to help in any phase of the custom SoC process.

To help manufacturers and companies that have never built silicon before, Arm has established the Arm Approved design partner program. This program provides introductions to audited chip design service companies, chosen for the quality of the services that they can provide, with proven success using Arm IP.

Case study 1: Valve controller for oil & gas company

Let’s look at a real example, courtesy of S3 Semiconductor. They developed a custom solution for a company in the oil and gas industry, designers of complex valve controllers that sense pressure and temperature.

For their next generation product, S3 Semiconductor’s customer decided to replace the many off-the-shelf parts with one integrated solution. The key drivers were to reduce costs, improve reliability, and simplify the inventory and supply management.

S3 Semiconductor built a low-power chip for them, based on a cost-effective process node of 180nm, integrating a digital-to-analog and analog-to-digital converters (DAC and ADC), and many communication interfaces, such as I2C, UART, SPI – all in a low-power design consuming 160uW/MHz. The results of the project are impressive, with large improvements in cost, power, and area:

- 80% bill of material (BOM) cost reduction

- 70% power consumption reduction

- 75% smaller PCB size

In addition, the new solution simplified considerably the inventory and supply management.

Case study 2: Disposable healthcare monitoring device

EnSilica were tasked to meet a “disposable” price point for a wireless device that monitors heart rate, respiration rate, and temperature for more than five days continuously. With a discrete solution, it was impossible to meet power consumption and feature requirements. EnSilica developed a SoC that achieved the price point and reduced BOM:

SoC BOM: $2.42 (compared to discrete BOM: $8.17)

NRE: $2.32 million

Break-even: only 1 million units

Beyond the silicon: software reuse

Assembling and manufacturing the chip is not the end of the project. Hardware has little value when not paired with software. If your software engineers are worried about the move to a custom part they can be reassured that developing, debugging and reusing software remains exactly the same. In fact, if they are using legacy 8 or 16-bit MCUs, then life is set to get so much better! If you are using off-the-shelf MCUs or CPUs today then moving those into a custom SoC, reusing your existing software investment and sharing new code with future projects is all possible and straightforward.

If you're thinking about a custom SoC, Arm DesignStart aims to reduce the barrier to developing chips, making the benefits more accessible than ever, regardless of budget or design expertise.

Get started today - explore the IP, tools, support and services available from Arm DesignStart for no upfront cost.