Another in a series of previews to Sensors Converge 2023

It is a great and interesting time to be involved in driving sustainable technology development and business practices for the electronics industry. It seemed we moved beyond the “greening initiatives” of the 2000s and the “climate change initiatives” of the 2010s to now have a focus on “sustainability initiatives” in the 2020s.

Please do not misunderstand. I am neither poking fun nor dismissing these initiatives simply because they are highlighted with quote marks. This comment was not meant to be cheeky, but rather to highlight the difference between catchy buzz words from executive keynote presentations on the one hand and actionable, serious resource investment to drive such initiatives on the other. In this author’s opinion, it feels like there has been a palpable shift from the lip service of previous decades to a more action-focused industry today.

The motivations for this more serious approach to sustainability are debatable and mostly beyond the scope of this short blog, but at a high level, any seasoned, industry stakeholder or business analyst will quickly tell you there must be a clear economic incentive. Conversely, this “incentive” can come in the form of avoiding penalties in terms of extra taxes/fees/overhead expenditures (in terms of capital and operational expenditures, a.k.a. – CAPEX & OPEX) that are typically dictated by some kind of governmental regulation.

In other words, companies are typically very happy to support a sustainability initiative when it also provides some kind of direct, financial or brand-awareness incentive. When it comes to sacrificing profits for the greater good, then much of the corporate goodwill and high-ethical standards suddenly find themselves the victims of priorities that do not quite have the right timing/resources to get funded.

The concept of greenwashing is also very prevalent in this space. While any focus on sustainability sounds like a good thing, especially when accompanied by actions that go beyond mere optimistic words, it is not uncommon to see sustainability initiatives/data be twisted to give the perception of much greater impact than is truly occurring. This approach is the concept of greenwashing. A simple test for greenwashing is when a company puts more resources into its marketing budget to communicate sustainable practices to the world than it puts into driving the practices themselves.

Carbon credits can be a quintessential example of greenwashing since it seems most of the “net zero” footprints and targets claimed these days are more the result of paper exercises and agreements to mathematically try and justify away what remain huge carbon footprints continuing to accelerate the planet on a negative path. Does it really matter how many trees a company pays a fee to plant somewhere else in the world if their dirty factory is still dumping massive toxins into the air/land/water and consuming large footprints of fossil-fuel-derived energy? I doubt the families living next to that factory are impressed with how many trees that company signed an agreement for, and paid to plant, in some foreign rainforest.

The next major change our industry should internalize is a concerted shift from targeting net zero to targeting actual zero. This is the logical, evolutionary step to get our industry (and global civilization for that matter) onto a path of perpetually-sustainable design engineering, supply chains/manufacturing, and business payback calculations. We must get away from the mindset of paper and mathematical efforts that essentially simulate a zero-carbon mentality (hence “net zero”) and put fierce effort into converting any non-zero footprint process/product into “actual zero” in a pragmatic way that impacts the immediate, surrounding environment.

Deployment of renewable energy sources (i.e. – solar PV, wind, fuel cell, etc.) are great examples, but only when combined with an intelligent energy storage solution that can ensure energy independence even in the face of energy intermittency. More importantly, these deployments need to be anchored around the geographic regions of utilization for their impact, in terms of a reliable source of “actual zero” for the user as well as compatibility with the local communities directly impacted, to be truly felt.

A key enabler here is the consideration of end-of-life (EOL), recycling, and e-waste mitigation that must be prioritized as an important consideration from product/design inception. This point is particularly salient as many sensor-based systems (i.e. – IoT/IIoT, wearable/trackers, conditional monitoring, asset tracking, preventative maintenance, etc.) are exponentially growing in numbers and ubiquity in so many application spaces. These uber-sensorized deployments and service-based business models are driving a paradigm shift toward a circular economic model in the development and economical, sustainable utilization of electronics.

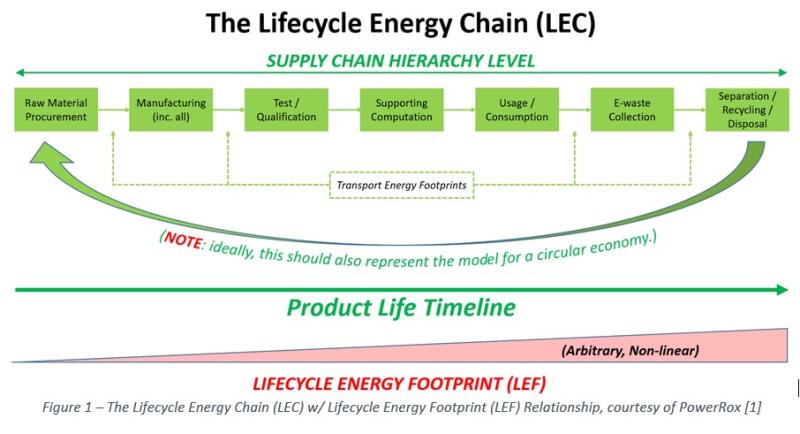

The figure below breaks out the constituents of various carbon/energy footprints over the life of a product, but also in the context of a circular economy, which forms what is referred to as a lifecycle energy chain (LEC). The lifecycle energy footprint (LEF) is a metric proposed to aggregate a product’s absolute, total energy footprint from cradle to grave (a.k.a. – embodied energy).

The Lifecycle Energy Chain (LEC) with Lifecycle Energy Footprint (LEF) Relationship, courtesy of PowerRox [1]

Without a focus on what sustainability truly means and seen through the lens of absolute energy footprints (as described above), then a ride on the perpetual, merry-go-round of greenwashing. Fortunately, there is currently a lot of investment and focus on implementing a sustainable electronics industry. With proper awareness and education on energy footprints, this momentum can be funneled into efforts to truly move the needle. There is a lot of money to be made in this space even for people who could care less about the environment so being green is actually green ($$$)!

Many sustainable design techniques and best practices will be covered as part of a pre-conference, half-day symposium supporting this year’s Sensors Converge 2023 event, which focuses on energy harvesting and driving a sustainable, power IoT ecosystem. Come learn more about all this and more in the pre-conference symposium “Extending Battery Life to Empower the IoT/IIoT” on Tue, 6/20/23, 9 am – 12 pm PT (https://sched.co/1GzqW), which will include a bonus functional demo session of EH technologies/solutions after the talks. In addition to four, top-notch speakers, there will be an interactive panel session to engage the audience as we all discuss how “The EH / Power IoT Ecosystems Enter the Mainstream” as a group. This symposium is just one small part along with many more great contributions to the overall Sensors Converge 2023 program (https://www.sensorsconverge.com/sensorsconvergecom/schedule)!

[1] IEEE Future Networks Initiative - Energy Efficiency Working Group, "Energy Efficiency, 2023 Edition" International Network Generations Roadmap (INGR), July 2023. [Online]. Available: https://futurenetworks.ieee.org/roadmap.

Brian Zahnstecher is a senior member of the IEEE, Chair (Emeritus) of the IEEE SFBAC Power Electronics Society (PELS), IEEE PELS North America Regional (R1-3) Chair. He sits on the Power Sources Manufacturers Association (PSMA) Board of Directors, is Co-founder & Chair (Emeritus) of the PSMA Reliability Committee, Co-chair of the PSMA Energy Harvesting Committee, Co-founder & Co-chair of the EnerHarv workshop, and is the Principal of PowerRox. He Co-chairs the IEEE Future Directions (formerly 5G) Initiative webinar series and is the founding Co-chair of the IEEE 5G Roadmap Energy Efficiency Working Group and has lectured on this topic at major industry conferences. He previously held positions in power electronics with industry leaders Emerson Network Power (now Advanced Energy), Cisco, and Hewlett-Packard. He has nearly 20 years of industry experience and holds Master and Bachelor degrees from Worcester Polytechnic Institute.