Wireless sensors and other wireless products are becoming more readily available, but only a few vendors are offering unique radios. Most offer repackaged radios from one of the major industry suppliers. The implication here is that the vendor selling the solution may not be knowledgeable about the radio link in the product.

This leaves you, the user, in a quandary. Because you can't count on the vendor for assistance, you must become the expert yourself. To help you cope with this situation, we're going to look at the characteristics of an ideal wireless sensor and attempt to provide benchmarks against which you can compare and evaluate emerging products.

A Profile of the Ideal Wireless Sensor

- The ideal wireless sensor should:

- Have adequate battery life

- Transmit over adequate distances

- Avoid EMI

- Provide plug-and-play compatibility with multiple products from multiple vendors

- Be suitably small

- Be self-powered, self-configuring, self-calibrating, self-locating

- Provide a secure (undetectable) RF signal for communications

- Have adequate battery life

In addition, the device should have sufficient onboard intelligence to reduce the bandwidth it requires, but it should provide a high-bandwidth connection, just in case. All connections should be verifiable, with no errors in the transmission no matter how bad the RF environment or how obstructed the RF path might be. Finally, the sensor should be able to respond to such requests as scan faster, activate the actuator, or change your node address. Above all, the ideal wireless sensor would be low cost.

All these features require technological underpinnings to support the functions. Performance is tied to an underlying design, and understanding the design can help you recognize performance potential. Now we'll look at these properties and examine what technologies might provide solutions (or at least help).

Power—Less Is More

The key to extended battery life is energy drain. For the most part, all suppliers have access to the same battery technology, so battery life is a function of how efficient the design is with respect to information conveyed per milliwatt hour of energy consumed. Note that the real issue here is how much energy is consumed, not how much power is used.

Some of the approaches available to a designer in managing battery life include power harvesting, power management (e.g., duty cycle), embedded intelligence, spread-spectrum process gain, low-power designs, battery technology, diversity, and battery capacity. Some of these interact with other issues, so a systems approach is necessary for a viable design.

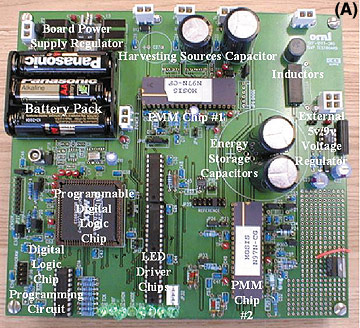

Power Harvesting. The solar cell (photovoltaic) is the most familiar form of a device that harvests energy from its environment. Other designs harvest energy from vibration, temperature differences, electromagnetic fields, and chemicals present. The Navy's Reduced Ship's Staffing Through Virtual Presence (RSVP) project funded research and development at Draper Labs and Oak Ridge National Laboratory (ORNL) to look at harvesting energy from the shipboard environment and using it to power wireless sensors. Computational Systems, Inc. (CSI), uses a photovoltaic device to recharge the battery in its wireless sensor. Wristwatches have harnessed energy from the wearer's motion for years. The latest such technology from Seiko is being investigated for other uses. Seiko can now harvest energy from the motion of the wearer (Seiko Kinetic), using a miniature mechanical generator, or from body heat (Seiko Thermic), using the Seebeck effect.

|

Power Management. Seiko's efforts in harvesting energy would be fruitless if they weren't also taking care to manage energy drain and storage. Their designs stop the timekeeping after several days of activity and then restore the time (stored in memory) when reactivated. The designs can hold the time for as long as four years.

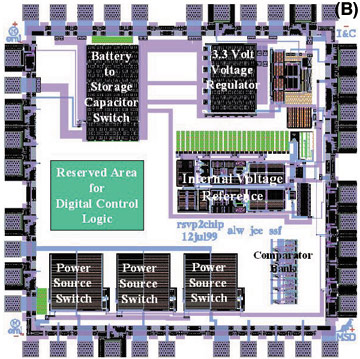

Other energy management techniques extend the life of batteries in cell phones, laptops, and other portable electronic equipment. The design for the Navy's RSVP project includes an ASIC that optimizes the energy use of wireless sensors based on the energy source and load (see Photo 2).

|

The chip's algorithm looks at which of several harvesting options is currently generating sufficient energy for the unit and how it matches power demand. Designing wireless sensors for maximum battery life will require attention to power management.

Embedded Intelligence. This approach offers the most significant opportunity for energy management. The amount of data being transmitted directly affects battery life. For example, a sensor that transmits the entire spectrum from an accelerometer must sustain a higher data rate than one that can intelligently decide if the spectrum is normal and, therefore, may not need to be transmitted.

CSI's wireless sensor monitors electric motor health. The sensor's embedded intelligence lets it suppress unneeded status transmissions. The technology implementing the intelligence, though, can drain the battery faster than the transmitter. A new generation of low-power DSP chips offers opportunities for reducing the power required in an intelligent sensor.

The techniques described here not only improve battery life but can also reduce the transmission power required for a specified range along a given signal path. This reduces the likelihood of interference, another important attribute for industrial wireless systems. The goal of these systems is to transmit the information with the lowest power level possible.

Another technique for increasing range is to use a multihop network (e.g., the Internet). The problem here is where do you store the routing table? If the node that contains the routing table becomes unreachable, the entire network will be affected. Mobile ad hoc networking is a technique used to maintain a dynamic routing table. The technology allows wireless sensor networks to be self-configuring as sensors enter and leave the network. Because this is a hot research topic, you're likely to see some extraordinary claims from suppliers who are trying to provide the functionality while not understanding the underlying technology.

Process Gain. This critical technique reduces battery drain in wireless communications systems. In any spread spectrum transmission, process gain can be shown to be equivalent to 20 db Log(chip rate). This means that a design that chips a bit into 100 sub-bits results in a process gain of 40 db. This is equivalent to 20 db in power gain at the receiver with no increase in transmission power. The act of chipping does draw power, however, so sound system design is required.

Process gain can't be used to penetrate an environment dominated by Gaussian white noise. But fortunately industrial environments are usually limited by narrow band, intermittent noise caused by arcs, motors, and lighting. In these environments, process gain available from the chipping rate can be a significant source of overall system gain. The electronics required to perform the high-speed chipping has been cost prohibitive in the past, but recent innovations driven by the cell phone industry are making new designs feasible.

A key parameter here is the energy per bit. The more energy put into each bit transmitted, the simpler the receiver can be. Because the receiver is always the most difficult part of the network to design and build, reducing the cost of the receivers reduces the cost of the network.

The more energy per bit, the more likely the bit will get through. Spreading the bit in spectral, temporal, spatial, or polarization domains (increasing diversity) makes it less likely that interference will corrupt the transmission. This is a tradeoff with throughput, though, because the more energy you put in each bit, the more energy needed for the total transmission. Again, embedded intelligence is key because it ensures that raw data aren't transmitted needlessly.

Many vendors are selling systems that don't sample at the sub-bit level. All currently available frequency-hopping, spread spectrum (FHSS) systems are "slow hoppers"—the rate at which they move from one frequency to another is slower than the bit rate. They send multiple bits on each narrow band channel before they move to the next channel. This results in a system with no process gain, but it does have some of the advantages of a spread spectrum transmission.

All direct-sequence, spread-spectrum (DSSS) systems subsample the bits, so they exhibit some process gain. IEEE 802.11 (wireless Ethernet) uses an 11-bit spreading code in the DSSS version, so they sample each bit eleven times. Robertshaw, a maker of industrial wireless products, has a line of products that uses a 63-bit spreading code in a DSSS design. DSSS is inherently similar to a technique used for years in industrial measurements: modulating a DC level to improve the SNR for transmission. In this case, each bit is exclusive-ored with a high-rate chipping pattern that can be demodulated in the receiver because it knows the chipping pattern used for each channel.

Low-Power Design. Research in smart antenna arrays is showing that battery life can be extended even further. Sophisticated designs "beam form" on the incoming transmission, increasing directional gain. Active power control signals can then be used to reduce the remote transmitter power and save battery power, but this requires two-way communication in all nodes. Again, the cell phone and wireless Internet industries are leading the activities in these areas. The Mobile and Portable Radio Group (MPRG) at Virginia Polytechnic Institute and State University performs extensive research in smart antenna designs and supports some of the major players in the marketplace.

Anything that reduces errors in transmission can extend battery life because errors often require retransmission of the entire packet. The tradeoff among bit error rate (BER), transmission power, forward error correction (FEC), and other techniques for improving the likelihood that the information will get through makes system design critical for reducing power drain and enhancing battery life.

New techniques allow dynamic allocation of FEC bits. This means the system can achieve higher throughput when noise levels are low and sacrifice throughput only under higher noise conditions. The downside is that packets that are lost will need to be retransmitted. The dynamic environment for noise in industrial environments could cause problems as the process continuously re-evaluates the need for error correction versus throughput.

IC design greatly influences the power demands of the system. The metric in transmitter design is the power transmitted versus the power drained from the battery. As more of the power comes out as RF energy, the more efficient the design. In receivers, the figure of merit is the quiescent current drain during receive. The operating voltage has an influence, too. The lower the voltage, the lower the energy consumption. Sometimes, though, inefficient converters are used to bring the voltage back up, so the energy consumed can actually go up when the voltage is reduced. The final output stage of the transmitter may require a higher voltage than the rest of the circuit, so careful design is again necessary.

Diversity. One of the design approaches used to help ensure a robust signal path is known as diversity. This approach is built on the fact that a spread spectrum signal is inherently diverse. Techniques are now being applied to take better advantage of the diversity offered by the base approach.

New designs (especially in the cell phone markets) are taking advantage of spatial, spectral, temporal, and polarity diversity. Spatially diverse systems support multiple antennas, so techniques can be applied for directional gain and noise rejection. Spectral diversity is inherent because the signal is spread over a range of frequencies for transmission. Temporal diversity can be obtained by a technique called interleaving (see Figure 1).

Figure 1. In wireless communications, you can use chip interleaving to improve diversity. To implement this process, each bit stream is X-ored with the pseudo-random chipping pattern to produce a chip stream (A, B). Individual chips are extracted from the incoming chip streams to produce an interleaved chip stream (C). This creates a chip stream in which chips from the original bit stream are not necessarily serial in time. Any time-domain interference is then less likely to wipe out an entire bit. The receiver is programmed with the same pseudo-random codes for the X-or and de-interleaving operations. |

Chips (i.e., subsamplings of individual bits) are scrambled in a pseudo-random way, transmitted, and then reassembled in the receiver. Because the chips from bit 1 are spread out in time as well as frequency, the likelihood of a noise pulse interfering with the entire bit is reduced. This technique is used in personal computers for storing information more reliably on the hard drive. You achieve polarity diversity by using circularly polarized RF transmission signals. Because a clockwise polarized signal is orthogonal to a counterclockwise signal, information can be sent on both channels. Turbowave, Inc., has developed a product line for mobile LAN applications that takes advantage of this technique.

Battery Technology. The main issue in energy storage is most likely the required maintenance (read replacement). The initial cost of a cell is usually quite low, but if the sensor must be retrieved and serviced to replace a dead battery, the maintenance cost may be unacceptable. For that reason, the primary figure of merit is battery lifetime.

For systems where the batteries are recharged in situ, the issue of time between charges becomes critical from an operational perspective. But even rechargeables eventually must be replaced. The specification is usually quoted as the number of recharge cycles before failure. Because this is also related to battery capacity, the correct quote will include a graph of battery capacity (in milliamp hours) versus number of recharge cycles.

The debate over nickel-cadmium, nickel metal hydride, lithium ion, and other chemistries continues. New battery manufacturing techniques permit conformal batteries, where the cells are actually formed from thin film structures (much like semiconductor IC fabrication) in

|

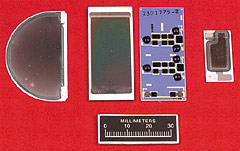

Integrated Power Solutions, Inc., recently received a license to commercialize a new battery technology developed at ORNL. The thin-film, lithium rechargeable cells offer tens of thousands of cycles with no degradation in capacity (see Photo 3). The company is very interested in the wireless sensor market for its new cells.

On the other hand, some devices don't use batteries at all. The "bee chip" in Photo 1 uses a capacitor to store energy. Most RFID devices harness energy from an interrogating beam and retransmit a radio signal from the energy obtained. These are short-range devices, but they have a long life because no batteries are involved.

Extensibility—Standards and Technology

A truly extensible system should accept new devices or upgraded devices from various vendors. Sometimes even devices from the same vendor can't be deployed beyond a limited number. For instance, a well-known vendor of wireless digital voltmeters once cautioned buyers that devices installed close to one another could generate interference. Today, however, most vendors supply systems that accommodate a reasonable number of devices in the same RF environment. But the buyer still needs to ask the questions. And don't just ask if it is possible to add new devices—ask how difficult it is.

The IEEE 802.11 wireless Ethernet standard was the first over-the-air standard available on the market. Cell phone providers, of course, have their own standards, but they're not available to others. Like most standards, there's enough leeway that some products meeting the standard still won't play well together. A good overview of the standard and physical layer options can be found at "What is the IEEE 802.11 Standard?" In addition, new standards are emerging that could be useful for industrial measurements.

The Bluetooth standard offers remarkable potential. Although many detractors argue that it won't be suitable for industrial measurements, it really is too early to dismiss it. A new wireless sensor focus group has been formed under Oceana Sensor Technologies' Bill Nickerson, and Crossbow Technologies is now offering the CrossNet system, which uses Bluetooth with its wireless sensors.

It looks like Bluetooth will actually be incorporated in the IEEE 802 standard as IEEE 802.15. Technologically, Bluetooth is a FHSS system (slow hopping) that operates in the 2.4 GHz band with a limited range. It's designed and marketed for home and office automation environments. Use in industrial environments has raised some concerns, but with enough pressure from industry, these concerns may be either reduced or eliminated.

The IEEE 1451 smart sensor standard currently requires a wired interface. Some of the committee members are considering a wireless physical layer for inclusion in the standard. This would give industrial wireless suppliers a new option.

Technology plays a role in extensibility, as well. The number of units that can coexist can be a function of the technique used for multiple access to the RF channel. Techniques used include time division, frequency division, or code division multiple access (TDMA, FDMA, and CDMA, respectively). TDMA requires that each device have a allocated time slot in the channel. Graviton is developing a wireless sensor suite using TDMA and low-power designs. FDMA requires a separate frequency for each device. CDMA is the only technique that allows all devices to broadcast simultaneously on the same frequency with a sufficiently high chipping rate without interferring with each other. Because the CDMA codes are orthogonal, each channel looks like white noise to the others. The limit of the background noise is a function of the system design and results in practical limits in the hundreds of units. The MPRG has published extensively in this area of research. The CrossNet and Centeron (Robertshaw) systems are examples of CDMA systems. Hybrid techniques are drawing interest as well. The critical question remains, how many devices can coexist without a serious impact on cost or reliability.

A new technique, called ultra-wide band (UWB), spreads the signal over 3 GHz using a Gaussian monocycle and pulse position modulation. The technology holds the potential for long-range, low-power, low-bit-error-rate transmissions. But the technique has also led to potential interference problems.

An ad hoc working group (Ultra Wideband Working Group) has been formed to facilitate research and commercialization of the technology. And Time Domain, Inc., has good papers on ultra-wide-band technology on its Web site. The Federal Communications Commission is still investigating the potential for interference with other services because the wide-band transmissions are in restricted bands but at low power levels. UWB is not licensed for use in the unlicensed bands, but Time Domain has received exemptions for special products to be developed.

Throughput—More is More

The cell phone and wireless Internet markets are continually pushing for increased throughput, but the industrial wireless market appears to be a little different. A reliable connection is usually more important than blinding speed, but those in the industry do care about response time because they need equipment to respond quickly when commands are given. You can address this issue by selecting a higher transmission frequency, a wider bandwidth, or a high-tech modulation scheme.

Higher frequency carriers usually allow more signal bandwidth, and therefore more throughput. The Industry, Science, and Medicine bands used by most suppliers allow transmissions in the 915 MHz, 2.4 GHz, and 5.8 GHz bands. The push to the higher frequencies is usually driven by the desire for higher throughput.

For industrial purposes, though, there's a tradeoff. The lower frequencies usually do better in a non-line-of-sight environment, much like those you would find in most industrial settings. The higher frequencies suffer more attenuation with dust, moisture, and people in the signal path. They do offer some advantages in noise rejection, though, because most noise sources are in the lower frequencies.

The 2.8 GHz band is used for industrial RF heaters (e.g., microwave ovens) and can interfere with the low signal levels used in industrial wireless sensor networks. Most commercially available systems are in the 915 MHz or 2.8 GHz bands. Many organizations (including ORNL) are working to gain access to the 5.8 GHz band.

The modulation technique used in a communications scheme directly impacts throughput, too. Frequency modulation (FM) has yielded to such advances as phase shift keying. Binary phase shift keying (BPSK) has been the proven standard for most digital transmissions, but lately, quadrature phase shift keying (QPSK) is making progress.

As the names imply, these techniques modulate the phase of the carrier in ways that can be detected in the receiver. BPSK shifts the phase in each cycle so that a zero or one is determined by the presence or absence of the mid-cycle phase shift. QPSK offers four possible phase differences in each cycle. M-ary is the generic term for dividing the cycle into m opportunities for phase shifts. As you might imagine, the receiver gets tougher and tougher to design and build. This is a classic tradeoff between throughput and SNR.

The bottom line of many of these techniques is the number of bits per Hz of bandwidth. The current state of the art is about

1 bit/Hz. Systems performing higher than that are emerging, but they may have other problems because tradeoffs had to be made. The critical questions to ask here are what tradeoffs are made to get the increased throughput, and are they worth it in your application. Distributed intelligence can be used to reduce throughput requirements without sacrificing robustness.

Time for 20 Questions

Table 1 summarizes the desired attributes for wireless sensors and the technologies being used to provide those attributes.

|

TABLE 1 |

||||||||||

|

Technology vs. Attributes Summary Chart |

||||||||||

|

|

Technology

|

|||||||||

|

Attributes

|

DSSS FHSS UWB |

CDMA TDMA FDMA |

Low- power designs |

Mobile ad hoc net- works |

Power harvest- ing |

Embed- ded intelli- gence |

Diver- sity |

FEC

|

Open stand- ards |

BPSK QPSK M-ary |

|

Long range

|

NA

|

NA

|

NA

|

yes

|

NA

|

NA

|

yes

|

yes

|

NA

|

NA

|

|

Plug-and-play

|

DSSS

|

CDMA

|

NA

|

NA

|

NA

|

NA

|

NA

|

NA

|

yes

|

NA

|

|

Long battery life

|

FHSS

|

FDMA

|

yes

|

NA

|

yes

|

yes

|

yes

|

yes

|

NA

|

M-ary

|

|

Low RFI risk

|

DSSS

|

NA

|

yes

|

yes

|

NA

|

yes

|

yes

|

NA

|

NA

|

NA

|

|

Self-locating

|

DSSS

|

CDMA

|

NA

|

NA

|

NA

|

yes

|

yes

|

NA

|

NA

|

NA

|

|

Secure

|

UWB

|

CDMA

|

yes

|

NA

|

NA

|

yes

|

yes

|

NA

|

NA

|

NA

|

|

High throughput

|

UWB

|

NA

|

NA

|

NA

|

NA

|

yes

|

yes

|

yes

|

NA

|

M-ary

|

|

Non-line-of-sight

|

UWB

|

NA

|

NA

|

yes

|

NA

|

NA

|

yes

|

NA

|

NA

|

NA

|

|

Robust connections

|

DSSS

|

CDMA

|

NA

|

yes

|

NA

|

NA

|

yes

|

yes

|

NA

|

BPSK

|

|

Low cost

|

FHSS

|

FDMA

|

yes

|

NA

|

NA

|

NA

|

NA

|

NA

|

yes

|

BPSK

|

|

Small size

|

FHSS

|

TDMA

|

yes

|

NA

|

NA

|

NA

|

NA

|

NA

|

NA

|

BPSK

|

A "yes" implies that the technology offers an advantage in providing the functionality listed in the attributes column. An entry listing one or more of the technology options provides a likely order of priority for providing the feature. NA is listed where no particular advantage exists for that technology in facilitating the attribute.

Note that some technologies (e.g., CDMA) are difficult to implement in a low-cost sensor, so most suppliers will opt for the simpler TDMA or FDMA. In volume manufacturing, though, there is little cost advantage of one over another. CDMA would offer a significant technological advantage if it could be implemented at the same or lower cost than the other options. A buyer might then examine the product characteristics, look for the required functions, and then decide if the cost is suitable. If two products are offered at roughly the same cost, you might look to the one with the better performance.

The relative weights of the attributes will be a function of the particular application. The critical question is always what tradeoffs were made to get the property of interest. Many times, battery life can be extended at the expense of update rate or response time. Range can be increased with increased transmitter power, but that could cause more interference or reduce the battery life. Throughput can be increased, but at the cost of battery life and interference. Proprietary systems may offer the highest performance per dollar in narrow lists of attributes, but using these systems can force you into a situation where extensibility and maintainability are unacceptable.

Because all these tradeoffs are what make the system design viable, you have to be ready to ask the right questions to understand what the final performance will be in a specific application. Sometimes vendors will quote the battery life at the minimum throughput and transmitter power, but they will quote the range and data rates at a different setting for power and sampling. Let the buyer beware.

|