Ultrasonic sensors are known for their robust performance in harsh and problematic environments, where there are a variety of reflective forms and where precise detection is essential. Additionally, they are unaffected by target color, ambient noise, or dusty atmospheric conditions; they provide noncontact distance measuring; and their longer and wider sensing ranges help solve some pretty tough applications. Ultrasonic sensors bridge the gap between proximity and photoelectric sensing. They are ideal for applications that require a longer sensing distance than inductive or capacitive proximity detection can provide, that are too dirty for photoelectric sensors, or that involve unusually shaped targets. They are especially effective in detecting and monitoring objects with a relatively high density and high acoustic reflectivity, such as solids, liquids, and granular materials.

|

Ultrasonic Sensor Basics

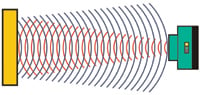

Ultrasonic sensors operate by using sound waves to detect targets (see Figure 1). A sensor generates a short, very intense sound burst from a piezoelectric transducer, which is reflected back by the object. The sensor determines the distance to an object by measuring the time that elapses between the emission of an ultrasonic burst and the arrival of the echo reflected by the target. This sensing method ensures reliable operation regardless of the object's color or opacity.

Figure 1. Ultrasonics determine distance with sound waves that are reflected back by the object being detected. |

The New Breed of Ultrasonic Sensors

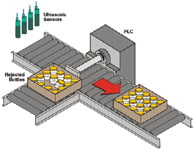

Today's ultrasonic sensors are available with improved capabilities that make monitoring easier, more precise, more efficient, and that offer greater control over command variables. In addition, multiplexing enables sensors mounted in close proximity to stagger their ultrasonic bursts to eliminate the possibility of two or more units simultaneously sending or receiving signals, a phenomenon known as crosstalk. It is especially effective on an assembly line, such as that shown in Figure 2, where multiple sensors are required to monitor products that are located very close to one another. The sensors can identify and reject any boxes that aren't full or have bottles lying on their side.

Figure 2. With multiplexing capabilities, sensors can be positioned so that they can monitor for missing or tilted bottles. |

The addition of serial communication capabilities is another enhancement. Pepperl+Fuchs offers a series of RS-232 programmable ultrasonic sensors that provide high-resolution control of switch point/span settings, compensation for turbulent or unstable target surfaces, and access to extended sensing ranges as well as other parameters. This lets you adjust a sensor for optimum performance under current application conditions and to display those parameters or measurement results to a PC.

To simplify the sensor programming procedure, a software program provides a communications link between an RS-232 programmable ultrasonic sensor and a Windows-based computer. Rather than manually typing in each command or parameter, adjustments are made with a mouse click (see Figure 3). The software lets you interrogate the sensor; display commands sent to, and received by, the sensor; and display the most recently measured distance. In addition, you can control sensing range and boundaries, (including extended sensing ranges), blind range (telling the sensor to ignore those objects directly in front of it and within a certain range); sensitivity (beam width), number of pulses evaluated per output, hysteresis, sound burst times, temperature offset, and output mode. Additionally, the program parameters can be stored on the PC's hard disk or on a floppy. Another feature allows a series of measurements to be initiated with the data periodically output in the form of a log. If problems are suspected, a log file can be recorded overnight. This is particularly useful when personnel are not available onsite to monitor sensor activity.

Figure 3. With PC software, the user can adjust a sensor for optimum performance under current application conditions. |

A programmable sensor could be advantageous in a variety of applications, including distance measuring in tight spaces and liquid level control for agitated liquids. In an application where distance must be measured in an environment with many side objects, such as pipes, cable trays, and racks as potential unwanted targets, reducing the sensitivity of the sensor can eliminate the possibility of detecting these peripheral objects.

The sensor can also be used for detection through a narrow "window" in a flat plate. Many applications require that a sensor be mounted out of harm's way so that moving targets or mobile equipment don't hit it. In such cases it is common to put the sensor behind a protective steel plate with a hole to aim the sensor through. In this case you may need to adjust sensitivity as well as blind range.

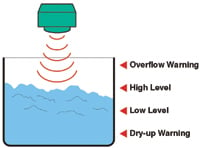

Ultrasonics are particularly valuable for liquid level control where contact with the liquid is not permissible and where turbulence and agitation eliminate the possibility of other sensing technologies (see Figure 4). This can sometimes be a difficult application, even for an ultrasonic.

Figure 4. A noncontact ultrasonic sensor continuously monitors the level in a harsh chemical environment inside a storage tank. |

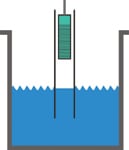

Using a stilling tube is one method used to eliminate instabilities—brief peaks and valleys in target levels that do not represent the true target position—caused by turbulent target surfaces. The tube creates a flat target surface suitable for ultrasonic detection as shown in Figure 5. While the stilling tube solves the instabilities of turbulent surfaces, it creates additional challenges for ultrasonic sensing. The tube must be completely smooth and free of bumps or jagged edges. The sensor must be centered within the tube and parallel to the tube walls. It cannot touch the sides. A narrow tube creates an environment that is conducive to false triggers. Droplets can accumulate on the walls of the tube, requiring adjustments to sensitivity, burst time, offset cycle time, and other parameters. These adjustments are typically not accessible without RS-232 programming capabilities and can cause a significant amount of downtime.

Figure 5. A stilling tube eliminates turbulence and creates a flat target surface for ultrasonic detection. |

Ultrasonic sensors solve tough problems. They have unique properties that satisfy unconventional and extremely challenging demands where other sensing technologies fall short. When combined with RS-232 programmable serial communication capabilities, they can make your process more reliable, make adjustments more precise, and make your job a whole lot easier.

Joan Kassan is Technical Writer and Jerry Morelli is Product Manager, Pepperl+Fuchs Inc., Twinsburg, OH; 330-486-0001, [email protected] , www.am.pepperl-fuchs .com