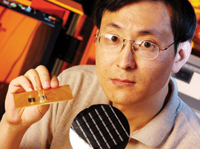

When ICs get too hot they can fail due to electromigration or as a result of the expansion rate differential between the silicon and the organic package substrates. As the power density of high-performance ICs increases, such as 3D multichip modules that cram more processing power into less real estate, conventional heat sinks will not solve the problem. Georgia Tech research assistant Bing Dang and colleagues Paul Joseph, Muhannad Bakir, Todd Spencer, Paul Koh, and James Meindl have devised a better way to chill the chips microfluidic channels.

|

"The challenge of 3D integration now," says Dang, "is that if you have several chips stacked on one another, there is no way to cool the chips in between. If we have microchannels on the back side of each chip, we could pump liquid through them and cool all of the chips."

The investigators first etch trenches >100 microns deep on the back of the wafer and then spin-coat a layer of high-viscosity sacrificial polymer onto the back of the chip to fill in the trenches and polish it to remove excess polymer. Next they cover the trenches with a porous overcoat and heat the chip gradually in a nitrogen environment to lose the polymer and leave the microchannels behind. Finally, they cover the overcoat with another polymer layer to make the system watertight. In the prototype version, the chips are cooled by buffered DI water circulated by a self-contained micropump. Experimental results indicate the microchannels' ability to withstand pressures >35 lb./in.2.

Calculations show that the system, which can have either straight-line or serpentine microchannel configurations, should be able to cool 100 W/cm2. The heat removal capacity depends on the coolant's flow rate and pressure, with smaller diameter microchannels more efficient at heat transfer.

The researchers have also built through-chip holes and polymer pipes connecting the cooling system to embedded fluidic channels built into a PCB. With flip-chip bonding, the channels can be connected when the IC is connected electronically.

The research was sponsored by the Microelectronics Advanced Research Corp. (Research Triangle Park, NC), and DARPA.

Contact Bing Dang, School of Electrical and Computer Engineering, Georgia Institute of Technology, Atlanta, GA; 404-894-9910,

[email protected], www.ece.gatech.edu.