|

Operating Principle

One new type of fiber sensor is the fiber Bragg grating (FBG) sensor [1,2]. Briefly put, an FBG is a portion of optical fiber whose refractive index has periodical changes along its length. It works as a partially reflecting mirror with a narrow (<0.2 nm) spectral peak. What is important is that the reflectivity peak's central wavelength is determined by the grating period (see Figure 1A). Under longitudinal strain, both the period and the peak reflectivity wavelength change. Under tension, the peak wavelength shifts toward longer wavelengths; under compression, it shifts toward shorter wavelengths (see Figure 1B).

|

This wavelength shift depends linearly on strain with a coefficient of ~1.2 pm/µ![]() . Similarly, the wavelength changes with temperature at a rate of 1.3 pm/°C.

. Similarly, the wavelength changes with temperature at a rate of 1.3 pm/°C.

To detect such changes in the peak wavelength, we must either measure the light intensity in a very narrow spectral window, or have a light source with a stable wavelength and narrow linewidth. In the former case, the input signal can be a broad-spectrum light source, such as superluminescent LEDs, with a narrow optical filter at the detector side whose wavelength is close to the center of an unstrained FBG's reflectivity peak. In the latter case, the input source can be lasers with stabilized wavelengths, such as temperature-stabilized semiconductor distributed feedback (DFB) lasers or fiber lasers. FBG sensors can measure strain or temperature at the grating's location. For measurements at multiple points (e.g., strain in buildings, bridges, or airplane wings), multiple fibers with FBG sensors must be installed.

FBGs can easily be made for different central wavelengths, so it is very attractive to use gratings designed for different wavelengths in a single fiber (see Figure 2).

Figure 2. In the multichannel interrogation system, the FBGs of different central wavelengths are used at different points of the fiber. Each FBG detects strain at its own fiber location. |

For instance, a multiple-channel interrogation system can be designed to measure strain or temperature at multiple locations using one fiber [3]. As in the single-channel systems, there are two ways of detecting the signal. In the first, a broad-spectrum source is the input signal, and either multiple narrow-band filters or a tunable filter is used for the detector. The second approach requires either multiple lasers with wavelengths adjusted to individual gratings, or tunable laser sources. Tunable filters and laser sources are attractive because they decrease the overall system cost. Their fast, repeatable wavelength sweep allows real-time monitoring of rapid changes in stress, extremely important for industries such as aircraft or shipping.

Tunable Sources and Filters for Fiber Interrogators

The important parameters of light sources for FBG interrogators are optical power, tuning range, tuning speed, and continuous tuning capabilities. For commercialization, manufacturability is also a key consideration. Several approaches to tunable sources and filters have been developed and commercialized (see Table 1).

| Table 1 | |||||

|

Comparison of Various Tunable Technologies for FBG Interrogation Systems |

|||||

|

Laser Type |

Optical Power |

Tuning Range (nm) |

Tuning Type |

Tuning Speed |

Manufac- turability |

| Broadband source with tunable filter | 0.02 per 1 A | 40 | Continuous | 100 ms | Low (hybrid integration) |

| Temperature-tuned DFB laser | 10 | 4 | Continuous | ~1 s | High |

| Multisection DBR laser | 1 | 40 | Digital (ITU grid) | 10 ns | Low |

| External cavity laser | 1-10 | 40 | Continuous | 100 ms | Low (hybrid integration) |

| Optically pumped VCSEL | 1-10 | 40 | Continuous | 100 µs | Low (hybrid integration) |

| MEMS-tunable VCSEL | 0.2-0.5 | 20 | Continuous | 100 µs | High |

First, let's consider a broad-spectrum light source with a tunable filter at the detector side. Tunable filters, based on a Fabry-Pérot etalon with moving mirrors, provide broad (up to 40 nm) continuous tuning at a speed on the order of 0.1 s. To achieve high measurement resolution, the tunable filter bandwidth has to be narrow, using only a small fraction of optical power (0.02 mW/0.1 nm of the band). Tunable filters typically require hybrid integration, making for low manufacturability.

Among the tunable laser sources we will examine are DFB lasers, multisection distributed Bragg reflector (DBR) lasers, external cavity lasers, optically pumped vertical cavity surface emitting lasers (VCSELs), and monolithic VCSELs with MEMS structures for tuning (see Figure 3).

Figure 3. Multisection distributed Bragg reflector (DBR) lasers, external cavity lasers, optically pumped VCSELs, or monolithic MEMS VCSELs can be used as tunable light sources for multichannel FBG systems. |

Temperature-Tuned DFB Lasers. These lasers are readily available commercial devices (Mitsubishi, Agere). Their optical power can easily be as high as 10 mW and their lasing wavelength changes continuously with temperature at a rate of ~0.1 nm/°C. So to tune over only 4 nm, the operating temperature should be changed by 40°C, which is close to the practical limit of the temperature

|

Multisection DBR Lasers. These fiber pigtailed lasers (Agility) are 4-5 contact devices that provide broad (up to 40 nm) tuning with a power of ~1 mW. Rather than being continuously tunable, they are switchable devices. They were developed for dense-wavelength-division multipleýed (DWDM) telecommunications systems, and tuned from one to another ITU (International Telecommunication Union) grid point separated by 50 or 100 GHz. Tuning can be as fast as a dozen nanoseconds, as determined by the electronic properties of the p-n junction. Very complicated processing technology makes their manufacturing difficult and the requisite elaborate controls complicate their electronics.

External Cavity Lasers. In these lasers, commercially available from Iolon and NewFocus, the output of the semiconductor laser chip is optically coupled to an external diffractive grating and tuned by rotating an external mirror. They have high power (1-10 mW) and continuous tuning over a >40 nm range, but have a fairly slow tuning speed (~0.1 s). Because of their complex optical scheme and hybrid packaging, they are quite complicated to manufacture.

Optically Pumped VCSELs. These complex optical systems, incorporating a pump laser and a vertical cavity laser with a tuning structure, require complicated hybrid packaging. Despite their 1-10 mW of power and continuous tuning over 40 nm, Nortel, their manufacturer, has discontinued them.

|

Tunable MEMS VCSELs

VCSELs, emitting in the 1.55 µm wavelength region, are very appealing laser sources for low-cost sensor systems because of their capacity to be tested at the wafer level. They also feature intrinsic single-longitudinal mode, low threshold currents, and low power consumption [4]. For MEMS-based tunable VCSELs, wavelength tuning is continuous and simply controlled by a voltage applied to the MEMS structure [5]. In contrast to other tunable lasers such as multisection DBR lasers, emission wavelength control over time implies only a closed loop on the voltage to compensate for any aging effects. This simplicity of tuning lends itself to very good operability in a real sensor configuration.

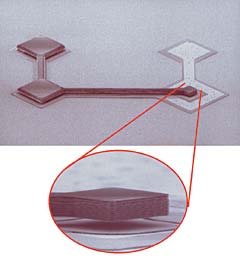

The operating principle of MEMS tunable VCSELs is shown in Figure 4.

Figure 4. In the MEMS tunable VCSEL, an applied tuning voltage controls an air gap between the cantilever tuning arm and the wafer base, which, in turn, defines the lasing wavelength. |

|

|

The most important characteristic of tunable VCSELs is the laser wavelength's dependence on the applied tuning voltage. Better than 20 nm tuning is achieved at 0-44 V (see Figure 6). The laser operates at a single frequency, with a side-mode suppression ratio >45 dB across the entire tuning range (see Figure 7) and at temperatures up to 75°C (see Figure 8), while maintaining a low threshold current. The laser linewidth is <200 MHz, or 1.5 pm.

Figure 7. The tunable MEMS VCSEL operates at a single frequency with a high side mode suppression ratio (>45 dB) across the entire tuning range.

|

The cantilever tuning arm is fabricated of a single-crystal semiconductor material and is very robust. At all tuning positions, its angular deflection is <0.1°, and has been experimentally demonstrated capable of surviving billions of tuning cycles. The arm's mechanical properties can be described through the spectral transfer function of wavelength vs. tuning voltage. Its mechanical resonant frequency is measured by turning the VCSEL on and monitoring the output wavelength change through a filter while sweeping a small modulated signal across the tuning voltage bias. The small signal transfer function of two typical MEMS VCSELs is shown in Figure 9.

Figure 9. The resonant frequencies of the tuning arms are ~80 kHz, as can be seen from the small signal response frequency characteristics of the tuning arms of two VCSELs. |

The arm's resonant frequency of ~80 kHz and damping time of <1 ms allow it to be easily controlled up to frequencies of 10-20 kHz. These features translate into a tuning speed of 400,000 nm/s.

Summary

Tunable MEMS VCSELs emitting in the 1.55 µm region have several advantages over competing technologies, among them a simple growth process and wafer-scale fabrication, testing, and screening. They are single mode, mode-hop free in operation. The cantilever and thin air gap make tuning simple, with only a single voltage applied to the tuning arm. The arm's mechanical structure allows tuning up to 400,000 nm/s across the entire tuning range. The arm is robust, with a failure rate better than 150 FITs (one failure per 1 billion device hours of operation). Finally these VCSELs are a highly manufacturable, reliable, and cost-effective solution for multichannel FBG interrogating systems.

References

1. Kersley, A.D., et al., "Fiber Grating Sensors," J. of Lightwave Technology, Vol. 15, No. 8, pp. 1442-1463, 1997.

2. Fuhr, Peter L., "Measuring with Light," Sensors, Vol. 17, No. 5, May 2000.

3. Lee, B., and Y. Jeong, "Interrogation Techniques for Fiber Grating Sensors and the Theory of Fiber Gratings," Fiber Optic Sensors, Ch. 7, F.T.S. Yu and S. Yin, eds., pp. 295-381, Marcel Dekker, New York, NY, 2002.

4. Yuen, W., et al., "High-performance 1.6 mm single-epitaxy-top-emitting-VCSEL," Elec. Lett., Vol. 36, pp. 1-2, 2000.

5. Chang-Hasnain, C., "Tunable VC- SELS," IEEE J. of Select. Top. Quant. Elec., Vol. 6, No. 6, pp. 978-987, Nov./Dec. 2000.