Environmental groups have lately been joined by the European Union in urging a ban on lead and certain other hazardous substances. One area the Reduction of Hazardous Substances (RoHS) directives will immediately affect is electronic equipment, which has historically incorporated lead solders and protective layers (there's a longer discussion of the directives in this issue). Such efforts to green up the world are all very fine except for the tendency of pure electroplated tin and lead-free tin alloys to spontaneously sprout metallic "whiskers" during their service lives. These filament-like structures can lead to electrical shorts and failures across component leads and connectors.

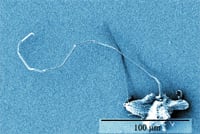

Colorized SEM of a whisker on a Sn-Cu alloy 176 days after electroplating onto a cantilever beam |

NIST researchers, in cooperation with the International Electronics Manufacturing Initiative (iNEMI) are investigating these whiskers, along with less annoying formations called hillocks, in an effort to prevent their development. It is generally believed that the electroplating process itself exerts stress on the underlying metal, and that hillocks and whiskers are a result of the metal's efforts to relieve that stress. The researchers are therefore trying to identify the origin of the stresses and thus better understand the consequent relief mechanisms.

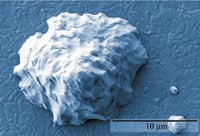

In a recent paper ("Whisker and hillock formation on Sn, Sn-Cu and Sn-Pb electrodeposits," W.J. Boettinger et al., Acta Materialia, Nov. 2005), the investigators reported that the surfaces of tin-copper deposits grew extremely long whiskers while pure tin deposits produced only hillocks. The two types of deformation are created when the boundaries between individual grains in a deposit are columnar. Lateral motion of the boundaries causes hillocks; when the boundaries are immobilized by copper impurities the result is whiskers. Tin-lead deposits, with their randomly structured boundaries, form neither.

Micrograph of a hillock on an electrodeposited pure Sn surface at 10 X magnification of whisker image |

The NIST researchers are now looking for ways to eliminate the stresses and to create deposit structures without column grains. One approach calls for substituting an AC ON/OFF electroplating process for the conventional continuous-current method. Their thinking is that doing so could disrupt the formation of columnar boundaries and produce a structure similar to that of a tin-lead deposit but do away with the lead.

Contact Bill Boettinger, National Institute of Standards and Technology, Gaithersburg, MD; 301-975-6160, [email protected], or Maureen Williams, National Institute of Standards and Technology, Gaithersburg, MD; 301-975-6170, [email protected].

Tell us about your research projects!

Could your investigations advance sensing and allied technologies, in the near future or years down the line? Let Sensors readers serve as your external sounding board, whether for pure or applied science and engineering.

Please direct inquiries and proposals to

[email protected].