One problem with every type of eyeglasses, contact lenses, and even the plastic lenses implanted after cataract removal is that they all have a fixed focal length. Auto-focus cameras don't, but they operate on a principle that wouldn't work for a pair of spectacles. Until now.

|

At the University of Arizona and Georgia Tech, optical scientists have demonstrated flat, liquid crystal diffractive lenses capable of changing their focal distance. According to researcher Nasser Peyghambarian, the prototype requires manual switching to change focal distance; the commercial version will do that task electroactively.

The lenses consist of two pieces of flat glass spaced five microns apart. The space between the panes is filled with liquid crystal. The glass is coated with a 0.1 micron thick layer of indium tin oxide, which functions as a transparent electrode and transmits most of the impinging light. Photolithography is used to arrange the electrodes in a circular pattern on the lens. The application of ~1.8 V to the circuit rapidly changes the orientation of the liquid crystal molecules and thus the optical path through the lens.

Prototype spectacles were shown not to affect distance vision when the glasses were inactive and enabled close-up vision when activated. The commercial models will probably be available first for those who require the use of bi- or tri-focals. Dentists are also expected to embrace the new technology because they must quickly switch from extreme close-ups of a patient's mouth to views of more distant equipment trays.

UA licensed three patents from the work to the Johnson and Johnson Development Corp., which sponsored the research. Pixel Optics has since purchased the patent licenses to commercialize the technology.

Dr. Bernard Kippelen, School of Electrical and Computer Engineering, Georgia Institute of Technology, Atlanta, GA; 404-385-5163, [email protected]

Lose the Leads Tekscan and SSI Wireless have teamed up to develop a line of flexible force sensors that require no leads. The basic sensor technology has been on the market for many years and has established itself in the industrial and medical markets in particular. Giving it wireless capability that will allow it to capture and store data collected at a distance of up to 100 ft. will facilitate many new applications.

(www.sensorsmag.com/0806/RDForce)

No-Antenna Radar

The U.S. Navy Super Hornets are being equipped with a new type of radar made by Raytheon. This technology is a departure from conventional radar in that there is no moving antenna. Instead, a computer directs the beams, each emitted by an electronic module, in the directions of interest. The process is rapid, and will allow pilots to concentrate on air-to-air and ground-to-air threats simultaneously. (www.sensorsmag.com/0806/RDRadar)

Get More from a Scan

The D-SPECT camera, introduced at the June meeting of the Society of Nuclear Medicine, features shorter image capture times, better image quality, and the capability of simultanrous multi-isotope imaging. Among the benefits of using more than one tracer and multiple isotopes are medical diagnostics for several conditions per scan. This will reduce the likelihood of radiation overexposure from repeated scans. (www.sensorsmag.com/0806/RDScan)

Safety Net for Miners

iPackets International Inc. will use the ARM7 system-on-chip 802.11 wireless technology for its next-generation compact iPMine-M8 810C tracking device, scheduled for market later this year. It promises to deliver a new safety net for miners, both above and below ground, by offering features including sensor processing, Voice over Internet Protocol (VoIP), and video streaming. The technology platform will also provide premium processing power to run the multiple features efficiently.

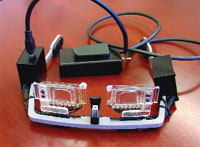

|

iPmine, handheld or equipment-mounted, is a real-time two-way wireless communications system that tracks, monitors, and communicates with miners and equipment. Location information is collected and displayed live on one or more monitoring stations against a background of the mine's terrain map. Redundancy makes its operation highly reliable for the harsh mining environment. (www.sensorsmag.com/0806/RDMines)