Industrial Automation computing requirements are continuing to evolve. In today’s systems, more end customers are looking for automation intelligence and data analytics to provide optimal efficiency of the factory automation process. There are some applications that only require the basics, which may be addressed in the programmable logic controller (PLC) often used in conjunction with a small computer board. But, the trend is towards more advanced computing requirements with scalable open architectures.

Open Standard Architectures

Open specifications and standards provide several benefits including multiple sources, scalability and upgrades, a large ecosystem of interoperable products, proven and tested designs, and much more. But they should not be confused with open source.

The open source groups tend to focus on specific product designs where even the Gerber files, schematics, and mechanical drawings are included. This lends itself to monochrome, commodity products with little differentiation. Open specification/open standard groups on the other hand define focus on common interfaces for interoperable products rather than finished products. Multiple vendors contribute to the base definitions and interfaces, but the implementation can vary greatly.

Industrial Automation and IoT require a lot of I/O and processor differentiation, so the open standards/specification route is often greatly preferred. There are also benefits of scalability, multi-vendor interoperability, and a broad ecosystem of proven products by utilizing open standard architectures.

There are four main types of open specifications used in industrial automation applications. These include:

- Standard motherboards, including Mini-ITX, Pico-ITX, etc.

- Computer on Module, including COM Express, Qseven, etc.

- Backplane based computing systems such as CompactPCI Serial, PXI, etc.

- Rackmount computers including PICMG 1.3, PCIe motherboard rackmount systems

In this discussion, we’ll focus on items 2-4 as they offer the scalability and performance required for many advanced industrial applications.

Many machine vision and industrial applications require some high-speed signal processing. While PLCs can handle a lot of the control requirements in the system, the embedded computer often provides many additional capabilities. This includes multi-core processing and PCIe lanes facilitating graphics capability for the user, communications (often GbE) to other parts of the factory, and a variety of I/O options (USB, LAN, DIO, etc.).

Another important element is expansion and scalability. To provide scalability for future growth or new requirements, the computing system should offer some expansion slots and/or the ability to easily upgrade replace part of the system via a mezzanine or other pluggable module. While many of these systems can utilize a rackmount computer, often space and weight is a concern. So, solutions like COM solutions are increasingly popular.

COM Express

First introduced in 2005, COM Express is a highly flexible technology and proven technology with multiple standard sizes. The concept of COM Express is that it has a mezzanine interface that separate two parts of the system -- the readily available core intelligence and a customized carrier board to provide I/O specific to the application. This also allows a designer to quickly design a solution as the majority of the work has already been completed with the pluggable module. It is also easily scalable/upgradeable to newer generations of mezzanines.

There are also a wealth of processor, I/O, memory, and size options with COM Express. The four main sizes for the architecture are:

- Mini: 55 × 84 mm (2.2 × 3.3 in)

- Compact: 95 × 95 mm (3.7 × 3.7 in)

- Basic: 95 × 125 mm (3.7 × 4.9 in)

- Extended: 110 × 155 mm (4.3 × 6.1 in)

The combination of the customized carrier and vast array of mezzanines types provides tremendous flexibility of designs that are tailored to an application. The carrier can be designed in-house or by many of the COM Express module providers, protecting your IP. As the computing requirements change in the application, the COM Express mezzanine can easily be swapped with a newer module. Plus, the carrier board can be designed for rugged applications – a useful feature in industrial settings.

Many of the modules in the industry meet -40C to +85C temperature for the most extreme environments. Many of the makers of COM Express are also experts in designs for shock/vibrations, IP65 for (or similar degrees of protection) dust/water/contaminant ingress, etc.

The “Basic” size tends to use higher power processor with more expansion for functionality.

More complex computer requirements in small form factor (SFF) applications may require its features. Increased memory capacity is also a benefit as you can reasonably fit two SO-DIMM slots. Typically, there are 32GB options (1x32 or 2x16 but not 2x32). The boards will also often feature a double connector (AB/CD) that provides the maximum allowable interfaces (PCIe, PCI, SATA, etc.). One key benefit of this is the capability to design with full 16 lane PCIe graphics. “Compact” is the middle approach where both Core I and low-power Atom, AMD processors are typically used. Often, they will go from the processor/chipset approach to a single chip or SoC design.

The available memory is generally halved to 16GB with a single slot (there are 2 slot options but memory capacity is still reduced as there’s not as much space to devote to data lines). Although these boards will still have a double connector (AB/CD) they may not provide all of the allowable interfaces.

PCIe graphics is still supported but we only get 8 lanes as opposed to 16. The “Mini” size is typically using only the lower power processors. This is the smallest size and engineers tend to use this approach if they only need a lower level of performance or have severe power or size restrictions.

The memory socket has been completely removed and is now onboard and capacity is lower. The Mini has the least number of interfaces and there is no longer the capability to support PCIe Graphics. So, most industrial applications would use at least the Compact size.

Advantages of COM Express:

- Versatile, many physical sizes and connector interface “Types”

- Easily tailored to your application and to upgrade

- Open standard with trusted PICMG organization

- Well established, large ecosystem

- Legacy interfaces are supported

- Ruggedized versions via carrier or clamshell

- Powerful processor option

- Low power options

The new Type 7 connector for COM Express R3.0 was introduced in 2017 and provides server-grade performance with up to four 10GbE connections. It may be overkill for some industrial automation and IoT applications, but it is beneficial to know that the potential performance is readily available if needed. See Figure 1 for an example of a COM Express R3.0 module.

![Embedded Insight 1 2017-09-21 Fig 1 [FIGURE 1] A typical COM Express R3.0 module.](https://qtxasset.com/styles/breakpoint_sm_default_480px_w/s3fs/Sensors%20Magazine-1505862392/FIG_1.jpg/FIG_1.jpg?itok=JJIfPMxx)

The push to higher performance and lower power consumption is a constant drive. The Intel Pentium D and Xeon D SoCs are popular for the Type 7 modules.

Backplane-Based Computing Systems

While the mezzanine approach COM modules provide in the form of scalable performance, many industrial automation systems are using backplane-based embedded computers. The benefit of this approach is a high-degree of long-term scalability and flexibility in multiple applications or as your single applications’ requirements evolve.

With pluggable and hot swappable modules, users can select from a wide variety of processors, graphics modules, storage boards, FPGAs, etc. With options for failover protection, the system can provide tremendous reliability and guaranteed uptime. There are both air-cooled (with fans) and conduction-cooled modules/systems for various applications and very flexible options for rugged/extreme environments.

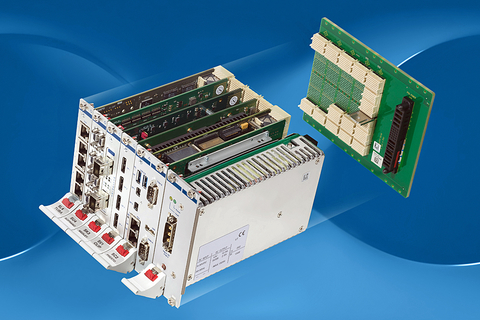

CompactPCI Serial for example, can run real-time PCIe Gen3 or 40 GbE boards across a high-speed backplane with a wealth of signaling options. In fact, the CompactPCI Serial backplane provides PCIe, USB2, USB3, SATA (1/2/3) and 10G Ethernet (Base-Tx) to each slot at the same time. The pinout has dedicated pins for each of these busses, so you can run all of them at the same time. See figure 2 for an exploded view of CompactPCI Serial modules and a backplane -the enclosure is not shown.

With just one voltage and with provisions for common protocols like USB and SATA, the cost gap to an industrial PC is getting smaller. CompactPCI Serial also has the potential benefits of hot swappability, better scalability and reliability, often less weight and physical space used, etc. But, some applications will still see benefits from industrial PCs.

Industrial PCs

The industrial PC is commonly employed in automation systems where the size and weight requirements are not demanding and the initial costs do not outweigh reliability and MTBF needs. The benefit of industrial PCs is the combination of expansion with a reasonably low-cost system. Industrial PCs have typically 7 slots with various configurations of x1, x4, or x16 PCIe Gen3 or PCI expandability. They often have several I/O options as well as multiple configurations of USB, serial, Ethernet, graphics, and audio ports. There are also versions with SATA port choices as well as RAID options. Although the daughter cards are not hot swappable, single or dual redundant hot-swappable power supplies can be employed. Of course, the costs will begin to creep up as you add higher degrees of reliability.

PICMG 1.3 (SHB Express) is an industry standard for edge-card processor cards in the industrial PC format. The specification includes an edge-card processor board and backplane combination that supports faster system mean time to recovery (MTTR) times, enhanced hardware platform stability, and increased support for industry-standard plug-in cards. This provides a wide diversity of applications the specification can be used in. The standard defines the routing of up to 20 PCIe base links from the system host board to a PICMG 1.3 backplane. Vision systems requiring higher speeds, reporting capability, and more reliability benefit from this type of approach.

The size of industrial PCs is typically at least 4U to support the size needed for the edge-card approach. Often vision systems have plenty of space and are okay with the additional weight. But, many designers are working to save as much space and weight as possible so the mezzanine and backplane approaches above are often employed.

Evolving Needs

As industrial automation evolves, the need for high-performance computing systems continues to increase. The versatility and real-time performance of mezzanine and backplane-based approaches give way to the next generation of factory automation, IoT needs, data mining/analysis, and more.

About the author

Justin Moll has been the Vice President of Marketing for PICMG since January 2017. He is also Vice President of US Market Development for Pixus Technologies and a dedicated consultant. Previously, Justin was Director of Marketing for VadaTech and for ELMA Bustronic. Justin is the Chair of the Higher Speed Ethernet Fabrics for MicroTCA.0 and AMC.2 committee in PICMG. For more details, visit www.picmg.org.