The Solid State Sensors, Actuators, and Microsystems Workshop, or as it is more commonly known, the Hilton Head meeting, was held June 4–8, 2006, in Hilton Head, SC. This is one of the premier venues for researchers and development engineers to exchange information on the latest advances in microsystems. This thirteenth biennial assembly featured a number of commercial products that use MEMS (microelectromechanical) technology and some MEMS devices very near the commercial product stage.

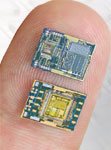

This month s cover photo is courtesy of the Engineering Research Center for Wireless Integrated Microsystems (WIMS, www.wimserc.org, an NSF Engineering Research Center). The background image shows wafer-level integration of vacuum-sealed capacitive pressure sensors. On the fingertip are front and back views of a fully integrated microsystem for autonomous data gathering. |

MEMS devices began serious commercialization in the late 1970s in response to the demand for automotive pressure sensors and have continued to expand in both automotive and non-automotive applications. Here is a short review of some of the devices already commercialized and some sensors that are nearing commercialization.

Microphone

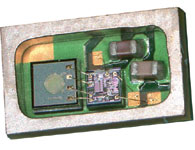

The Knowles SiSonic (www.knowlesacoustics.com) microphone is targeted at the low-cost, high-volume consumer electronics market. SiSonic is a condenser microphone comprising a MEMS die and a CMOS die in an acoustic housing (Figure 1). The one distinct advantage this microphone has over the electret condenser microphone (ECM) is that it can withstand the lead-free solder reflow cycles. The ECM must be inserted after the reflow cycles because it cannot withstand the reflow temperatures. This ability to be reflowed with other components permits the MEMS microphone to be pick-and-placed like any other component and thus leads to a lower cost for the integrator.

Figure 1. SiSonic condenser microphone package with lid removed; this is a first-generation version; subsequent generations have been developed |

Near-Infrared Analysis Tool

The Polychromix Phazir (www.polychromix.com) is a handheld NIR analysis tool and is made possible by an innovative MEMS optical modulator. The near-infrared portion of the spectrum is particularly useful for solids and liquids analysis in the pharmaceutical and agricultural products industries. The unit can be used to collect application-specific spectra in the field. MEMS technology has taken a laboratory-quality device and made it portable.

The conventional way to perform chemical identification in many materials is to repeatedly measure the spectrum of a sample and then analyze that spectrum to identify characteristic absorption lines of target chemicals. This method can be expensive and time-consuming, and requires highly skilled technicians. The MEMS modulator makes analyses portable, flexible, and cost-effective. Moreover, many of the tasks can be performed by nontechnical staff with minimal training—and achieve the same high-quality results.

Viscosity Sensor

A device that will be on the market soon is the Rockwell Scientific (www.rockwellscientific.com) MEMS viscosity sensor. Viscosity is one of the key parameters, along with total acid number, pH, water concentration, anti-oxidant concentration, and particle size, used to evaluate the remaining useful life of lubricating fluids. This sensor operates submerged in a fluid and senses the resistance to actuation due to the viscous drag forces on the fluid. The device is actuated and the time response of motion is measured to determine the viscosity. Due to its small size (2 x 2 mm) and limited fluid sampling requirement (20 µL), the device can easily be mounted inside the lubrication reservoir of any piece of equipment to monitor viscosity degradation during operation. The preliminary data look promising, but long-term reliability data need to be collected in order to ensure a fully characterized device for commercialization.

Wireless Chemical Sensor

The Georgia Institute of Technology reported on wireless ceramic chemical sensors capable of operation in high-temperature environments. They take advantage of a passive wireless resonant telemetry scheme that eliminates the need for onboard power and exposed interconnects. An inductor-capacitor resonator circuit forms the basis for the wireless platform. The sensor inductor is formed by electroplating nickel, and the capacitor is fabricated by using mixed-oxide ceramic dielectrics.

The dielectrics exhibit variations in electrical properties with exposure to differing concentrations of CO2 and NOx. The CO2 sensor is based on the conductivity changes in BaTiO3 -LaO3 and has been demonstrated to measure CO2 concentrations quantitatively at 675°C. The NOx sensor is based on the permittivity changes in ZnO-WO3 and has measured NOx concentrations below 5 ppm at 600° C. The researchers reported that the wireless sensing platform developed for these sensors can be readily adapted to detect a variety of other gases and even other phenomena by incorporating a dielectric that produces an electrical response to the phenomenon of interest.

Wireless Micro-Geiger Counter

The NSF Center for Wireless Integrated Microsystems (WIMS) at the University of Michigan reported on a magnetically enhanced wireless micro-Geiger counter. The device consists of a 1 x 2 cm2 micromachined glass/silicon cavity sandwiched between two miniaturized NdFeB rare earth magnets. Beta particles passing through the glass window ionize the surrounding gas atoms, resulting in an avalanche current pulse and consequent RF transmission. The micro-Geiger counter operates inherently as an ultra-wideband transmitter. The magnets modify the discharge path, providing an opportunity for increased ion-to-neutral gas atom collisions and thereby creating more ionized particles that enhance the wireless transmission.

Preliminary results show that the RF spectra in the presence of 90Sr and 204Tl sources of 0.1–1.0 µCurie increased by ~8 relative dB µV (compared to nonmagnetic devices) at a distance of 5 cm from the device. Increasing the field strength offers a larger transmission distance and a potentially wider sensing area.

Micro GC Column

WIMS also reported on a low-power micro gas chromatograph column (µGC). Such columns are critical for remote chemical monitoring systems serving homeland security, environmental monitoring, and health care applications, among others.

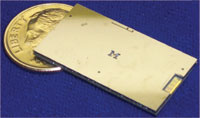

This was the first demonstration of a fully integrated microsystem that uses an injection system, a µGC column, and a flame ionization detector to allow it to measure a variety of gases. These high-performance, low-power µGC columns can separate 10 alkalines in <52 s and separate four chemical warfare simulants and an explosive stimulant in 60 s. Microtechnology allows the fabrication of 1 m columns with a footprint of ~2 x 4 cm (Figure 2). The columns' small mass makes it possible to achieve rapid temperature ramps with very low power. These results were obtained by using a ramp of 30°C–100°C at 50°C/min. The columns require 6 mW to raise the local column temperature by 100°.

Figure 2. Finished micro gas chromatograph column with a dime for scale |

Nanotechnology—On Its Way

Microsystems are now common in products ranging from engine controls, air bag deployment devices, ordnance, computers, and GPS, to name but a few, and ongoing research is leading to commercial sensors. As nanotechnology investigations into sensing technology continue, the number of new products will grow rapidly. Just as MEMS benefited from the commercial infrastructure for microelectronics, nanotechnology will benefit from the infrastructure developed for MEMS-based sensors. Workshops such as Hilton Head are both a measure of progress toward commercialization of leading-edge sensor technologies and a window to the future.

The technical digest of the workshop can be obtained for $140.00 by visiting the Transducer Research Foundation at www.transducer-research-foundation.org or calling 619-232-9499.

Joseph M. Giachino, BS Eng. Physics, MS Physics, can be reached at the University of Michigan, College of Engineering, Ann Arbor, MI; 734-615-3096, [email protected], www.umich.edu.