Of all the electronic components currently on the market, light-emitting diodes (LEDs) and the designs they fit into generate more press, discussions, and hype than any other. This is both understandable and justifiable because LED makers are the most prolific of all. They have to be since their work is never ending. There are always one or two more lumens they can boost and a milliamp or three they can trim while streamlining the final package.

LEDs are in literally every electronic device beyond just a semiconductor die and most would be hard-pressed to not count at least ten incidents of LEDs on their desktops alone. Right now, the big market for LEDs is general lighting and obviously it’s the one that generates the most news. Following close behind are the signage and displays markets. But there is definitely more happening than just LED bulbs replacing incandescents and fluorescents, big ad signs illuminating the landscape, and brightly backlit televisions.

The Main LED Market

Currently, the main market for LEDs is general lighting and the main focus of LED makers is getting the consumer public to fully embrace LED lighting, i.e., bulbs, fluorescent-like tubes, etc., as replacements for their traditional incandescent and cold cathode fluorescent (CCFL) components (fig. 1 and fig. 2). Based on the higher cost of LED equivalents, coupled with less-than solvent personal budgets and a general consensus that LED light quality takes a good deal of getting used to, getting consumers on board is a larger challenge than initially bargained for. However, IMS Research says the best is yet to come in this market sector.

FIG. 1: For functional home lighting, LED bulbs like Sylvania’s 60W component are screw-in replacements for traditional incandescent bulbs. Of course these LED equivalents last much longer and consume less power while delivering equivalent brightness levels, but cost a bit more.

FIG. 2: LEDtronics’ pendant lamps provide bright, functional illumination at an Amtrak train station. According to Amtrak’s analysis, the brighter and more directional 29-watt LED bulbs cut the transportation company’s annual energy cost by 80%.

Supposedly, the fruitful years for LED vendors in the general-lighting market will be 2013 to 2017 claims IMS Research analyst Jamie Fox who sees the market hitting $120 billion by 2017. Fox believes a peak will occur in 2017 with a shrink back to $105 billion by the end of the decade, despite the prediction that LED prices will plummet during that time span.

Sub Markets

For just LED chips alone, researchers at Strategies Unlimited predict a total 2012 market size in the area of $11.4 billion. According to DisplaySearch analysts, the market for organic-LED (OLED) is expected to hit a $44-billion mark in 2019 with OLED lighting products moving into the $6.3-billion spot by 2018. Additionally, if the folks at Global Industry Analysts, Inc. are correct, expect to see active-matrix OLED (AMOLED) components to log in around $14.4-billion by 2018. Bear in mind, only the LED chips figure is global; the others are for the US alone.

LED Applications

Applications for LEDs generally fall under one of three headings: functional, diversionary, and reactionary or unique. Of course, categorization is never a neat task since there is often intersection and overlapping and LED apps are only a bit clearer in this department. Functional applications for LEDs include general illumination, indicators and alarms, and signaling. By functional it’s meant that the application provides a necessary service. For example, LED bulbs light space so one can see where one is going, read, and physically function correctly and without accidents (fig. 3).

FIG. 3: Easing the transition from fluorescent lighting to more energy-efficient LED-based systems, TT electronics’ OPA779 series packs all of the benefits of LEDs into CCFL-like tube assemblies delivering a total luminous flux from 40lm to 1,80lm, with a maximum current drive range from 35 mA to 175 mA.

Another functional application example, signaling serves safety and operational services in motor vehicle and public-transportation markets. Traffic lights keep driving conditions organized and somewhat safe while LED signs provide information about road conditions, delays, and potential hazards. Indicators display what drivers are doing in relation to their fellow motorists, like turning left, right, stopping, or signaling emergency conditions.

Diversionary applications are those that serve no necessary function, in other words they are neither life saving or life altering (fig. 4). These types include advertising signage, TV backlights, and other non-essential informational displays such as decorative lighting (fig. 5). Not to be remiss here, these types of LED designs do serve a function. A large display promoting some product serves the functions of its creator: it diverts the target audience’s attention from anything other than the promotion. However, it serves no real function for target viewers in terms of providing critical information.

FIG. 4: For pure fun and diversion, “The Place” shopping center in the center of Beijing, China puts a lid on itself with this LED panel measuring 250 meters long by 30 meters wide. Installed for the 2008 Olympics, the screen displays seascapes, dolphins, and other shows. Las Vegas hosts a similar, yet larger panel measuring 460 meters long and employing 12.5-million LEDs.

FIG. 5: LEDs installed in waterworks can be both functional and diversionary. For example, the red led lights for hot water and the blue for cold (functional) and other colors are available for matching room décor or for certain seasonal themes.

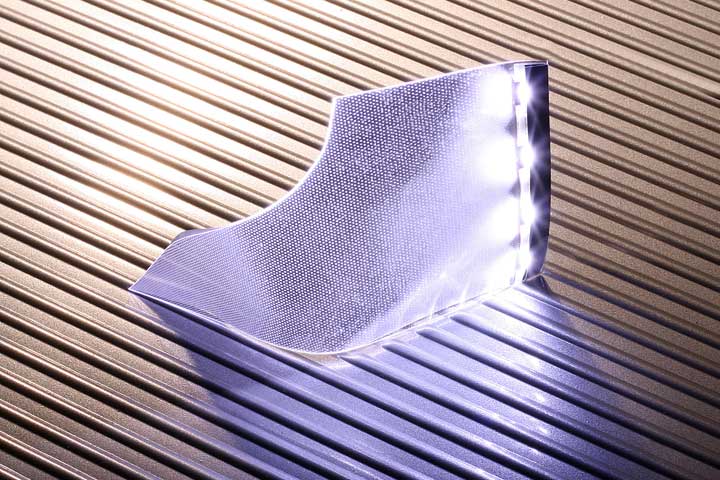

Not dismissing this sector as a mere distraction, there is a huge and thriving market under the diversionary umbrella. For instance, researchers at DisplaySearch believe demand for LED-based backlighting will represent the majority of total LED demand in 2015. They claim current demand for backlighting is 76% of total LED demand and expect it to be 50% in 2014 (fig. 6).

FIG. 6: Lumex calls its QuantumBrite component the industry’s first shapeable LED backlight. Measuring 0.125-mm high, the component is available in sizes from one to five inches squared, trimmable into any shape, and delivers brightness levels up to 20 cd/m2.

At The Fringe

The unique and reactionary applications are those one does not hear much about in the mainstream media unless it relates to functional and/or diversionary uses. They also include unusual designs, those that will do things that older technologies can’t. These are the applications that have evolved from designs previously relying on traditional incandescent or CCFL technologies. They do not react easily to LED revamps and require unique design approaches to adapt to the new components. They also include unique designs, those that will do things that older technologies can’t.

A lot of these reactionary and unique design approaches are surfacing in existing markets that include healthcare, medicine, and agriculture. They go well beyond just lighting up space with harsh white light or creating signs that tell one why they need to buy something just because it’s on sale. If the aforementioned predictions of a roll off in the demand for LED-based lighting products proves true, these unique applications will be significant drivers in future LED markets. They are the ones we will take a closer look at here.

LED Versus Laser Printing

When it comes to printers, most people think laser or inkjet. LEDs? Sure there’s a blinking LED or three somewhere on a printer to let you know it’s on, out of ink or toner, jammed, out of paper, or ready to self destruct. We don’t immediately think of LEDs playing a role in the print head, however several companies, Oki Data and Panasonic to name two, have been pitting LED printing against laser printers for some time now.

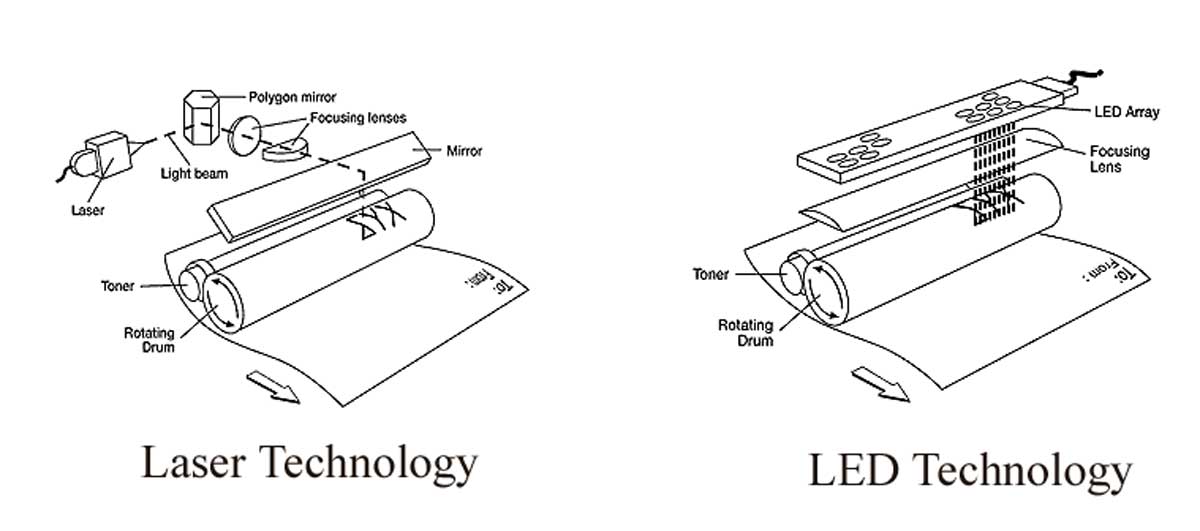

Both laser and LED-based printers work using the same technology photocopying machines have been using since their invention: electro photography (fig. 7). In laser printers, the electro-photographic process requires several steps.

FIG. 7: Laser and LED-based printers rely on the principle of electro photography but diverge at the scanning process. LED printers eliminate the scanner by using an array of small LEDs to generate the image.

First, a photo-conductive plate is charged with static electricity and, secondly, is exposed to an optical image via light. As portions of the charged plate selectively discharge, an image forms on its surface. The development step involves spreading a fine powder (toner) over the selectively-discharged plate. Toner sticks to the charged areas to create the printed image. Next, an electrostatic field transfers the image on the photosensitive surface to a sheet of paper and, finally, the image permanently fuses to the paper using heat and pressure.

Where laser and LED printers really part their ways is in the scanning process. Similar to electron beam scanning employed in older CRT monitors and TVs, laser printers use a laser beam and scanner assembly to form images one bit at a time on the photo-conductor. A controller modulates the laser beam and directs it through a lens and on to a polygon mirror. The beam reflects off the mirror and passes through a scanning-lens system that conditions and corrects the beam and scans it onto the photoconductor. On the other hand, LED printers rely on an array of small LEDs to generate the image, thereby eliminating the need for a scanner. This also translates into far fewer moving parts.

Both OKI Data and Panasonic have been promoting LED printers for several years, touting the virtues and benefits of the long-lasting and highly durable technology. OKI Data designers cite digital LED light sources as being far superior to laser-based systems. They reason that a multiple-LED source consists of thousands of individual solid-state light sources that shine directly through focusing lenses onto the drum surface. As the array stretches directly across the drum, the process eliminates all parallax errors and timing errors. There is also a theory that smaller dot size translates into higher resolution. Laser heads can produce dot sizes around 60 μm while digital LED technology can produce dots as small as 34 μm.

LED print technology is still fairly young and its higher quality and reliability in terms of fewer parts are enticing advantages for volume printers. The only minor drawback is LED printing tends to be a bit slower. Currently, both technologies are in the same ballpark pricewise. If future LED prices plummet as per analyst’s predictions, coupled with possible future environmental mandates, LED printing may go from unique to industry standard.

Tunable Light

The most interesting and challenging applications for light sources of any type involve adjusting the source to generate light within a given spectrum or at a specific wavelength. This adjusting of the light, also called tuning, can range from a fairly simple task to painstaking tedium cubed. Either way, target applications are not particularly in the mainstream’s top five.

Agriculture Apps

Grow lights, designed for inducing and promoting plant growth and health, are light sources tuned to emulate the natural light of the sun. There have been debates over whether photosynthesis in plants requires replication of the sun’s rays or just a consistent and mild form of white/yellow light. Whatever the theory or opinion, grow lights are a big business in agricultural, horticultural, and medical markets.

Grow lights are available in a variety of flavors with incandescent, CCFL, and LED being the most prominent and halogen, high-pressure sodium, and metal halide falling into smaller niches. Although full-spectrum light like the sun is the ideal, each light source has its natural range. Incandescent grow lights operate at a color temperature around 2700°K (fig. 8), white CCFLs operates across a color temperature range from 2700°K to 7800°K (fig. 9), and high-pressure sodium dominates around 2200°K. Metal halide components, depending on the type, span approximately 3200°K to 5500°K. Halogens sit around 3000°K.

FIG. 8: One of the most common types, the incandescent grow light operates at a color temperature around 2700°K.

FIG. 9: A bit more efficient than their incandescent counterparts, CCFL grow lights operate over a color temperature range from 2700°K to 7800°K.

All of these are not true full-spectrum light sources, but are viable for various growing strategies. For example, incandescent grow lights are good for indoor plant growing on a small scale because they are not very efficient and generate significant heat. In some cases though, the heat may be desirable for particular plant types. Fluorescent lights are suitable for indoor growing of vegetables or for jump starting seed blossoming. Usually employed to accelerate growth once a plant has reached mid maturity, high-pressure sodium lights accelerate fruiting and flowering. In the case of incandescents and CCFLs, some degree of color temperature tuning is possible by tinting the outer glass and/or using external lenses and filters. For small grow projects this is fine, but for bigger yields these methods quickly get both cumbersome and expensive.

Versatile LED Solutions

One would think that grooming LEDs with their fixed colors to accommodate the light requirements of the numerous varieties of plants and flowers would be a daunting task (fig. 10). For this particular application however, it may merely be a matter of mixing and matching.

FIG. 10: LED grow lights are amongst the most flexible in that they are available in numerous colors including basic white.

By mixing an array of LEDs, one can assemble a light source that generates just the wavelengths matching the absorption peaks of a plant's ideal photochemical processes. As there are numerous absorption peaks for the chlorophyll and other chemicals and enzymes involved in the photosynthesis process, pairing up a number of different-color LEDs can help cover all the peaks, achieving an all-encompassing spectrum of light for a particular foliage type (fig. 11).

FIG. 11: LED arrays for agricultural apps deliver full-spectrum light via a mixture of LED colors.

Set out and patented by inventors William Grant Anderson, Jr. and Larry Stephen Capen, a rule-of-thumb formula for creating an LED array that promises to maximize plant growth and vitality calls for a 6% to 8% ratio of blue light to red and orange light. For example, assembling an array of 12 red 660-nm LEDs, six orange 612-nm LEDs, and one blue 470-nm LED.

LED grow lights have several other advantages. These include significantly lower power consumption than the other types, they produce less heat, and they do not require potentially-noisy ballasts that are prone to failure in the long term. Just a note about power consumption. As LED technology advances, we are seeing a move from 1W LEDs to upwards of 3W and greater. Obvious this will translate into higher power-consumption levels in the future, though not significant when compared to current alternatives as well as the relevant increase in the size of the given applications.

Sophisticated LED Tuning

There are a plethora of situations and applications in which being able to tune LED wavelength (color) more precisely than mixing up a batch of different colors is not only desirable but absolutely necessary. Test and measurement, precision microscopes, aerospace, laser, light sources for machine vision systems, and medical are just a few that come to mind. In these cases, tuning needs to be both precise and reliable.

Color Mixing

One of the most sought goals of LED development is achieving the type of natural, white light similar to that emanating from a traditional incandescent bulb. Other than pleasing the eye of the general consumer, creating natural light becomes critical in lab and other test applications. One solution is to create an LED in the exact color wavelength to suit a particular application, a very expensive solution to say the least if all you need is just a few hundred LEDs. For economic viability, mixing color LEDs in arrays with external control suits the majority of applications.

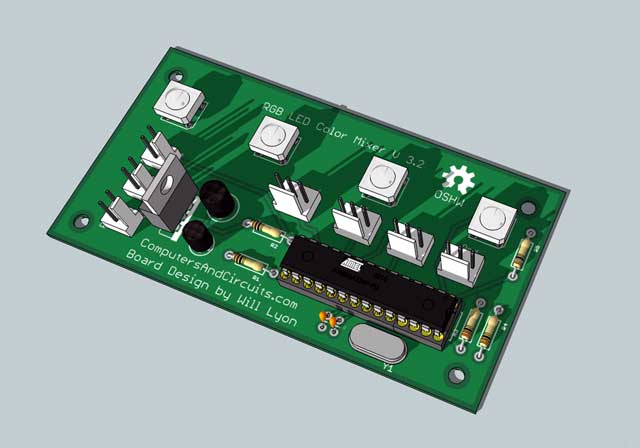

Although there are warm and cool white LEDs available, achieving a more natural light is the product of precisely mixing primary colors¾red, green, and blue (RGB)¾to attain the desired white light. You can actually produce white light by mixing just two primaries but this yields somewhat less than desirable rendition properties. Three-color RGB systems provide more acceptable results and offer the option to add extra colors for more accurate results. Additionally, mixed LED light sources exhibit higher efficiency, longer life spans, and enable better dynamic color control.

Combining primary-color LEDs in organized clusters allows users to not only sculpt natural white light, but near limitless variations of each color. Depending on the LEDs chosen for the task, i.e., warm, cool, bright, super bright, high power, etc., various intensities and subtleties are possible. Although the LEDs are the heart of the mixing array, control comes from external sources that include LED drivers and, in more sophisticated systems, microcontrollers or even a CPU in critical systems. Also, depending on the level of sophistication, high-level software may be involved.

Essentially, a simple mixing system is comprised of an LED cluster with separate LED drivers, integrated within one device, for each primary color (fig. 12). Adding MCU control, users can manipulate and vary drive current and/or duty cycle of each LED to produce changes in luminance and color.

FIG. 12: This simple RGB LED mixing system consists of the board and an integrated LED driver/controller. Software code enables total control.

Mixing systems do have their drawbacks. For one, there’s the part count ranging from minimal to complex. Next, if the system will be in use for a long time, light/color sensors will be necessary to monitor the LEDs since they tend to lose brightness with age. If the output color is critical, any changes in the brightness of an LED in the array will alter the color.

The Future of Tunable Lighting

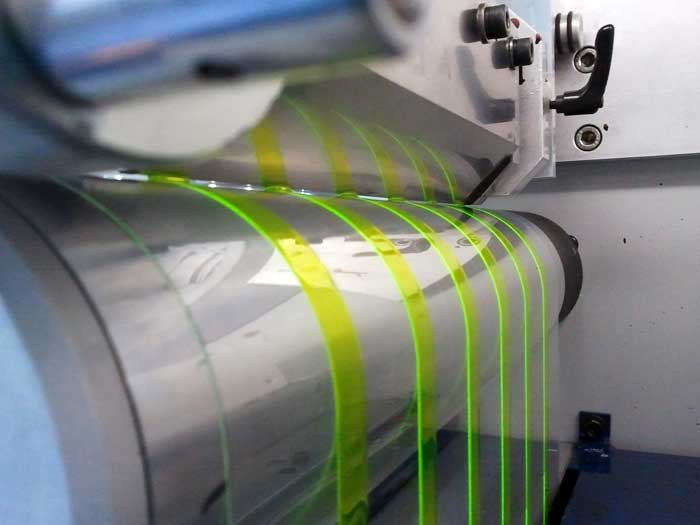

At the very least, there’s always something happening in lighting technology that always involves some permutation of the LED. One of the most interesting items on the drawing board right now is devices, or components, called electrochemical light-emitting cells (LECs). Described as alternatives to organic light emitting diodes (OLEDs), LECs have the same advantages as OLEDs plus a few unique features of their own like a very low turn-on voltage. Being solid-state devices, LECs generate light from electric current. They consist of two metal electrodes connected by an organic semiconductor containing mobile ions, about the only physical item that separates them from OLEDs (fig. 13).

FIG. 13: Alternatives to organic light emitting diodes (OLEDs), electrochemical light-emitting cells (LECs) generate light from electric current and consist of two metal electrodes connected by an organic semiconductor.

Another LEC advantage, it is possible to fabricate both electrodes from the same material because there’s no difference in electrode functionality. In addition to gold, emerging materials like graphene, carbon nanotubes, polymers, and blends of materials are viable. Notably, thickness of the active electroluminescent layer is not critical. Therefore, LECs can be manufactured using inexpensive printing processes.

All these advantages are very nice on paper, but the real kicker in the realm of light apps is this. Scientists, Jiang Liu, Isak Engquist, Xavier Crispin, and Magnus Berggren from Linkoping University in Norrkoping, Sweden are combining LECs with transistors to create light-emitting electrochemical transistors (LECTs). As a result, they can demonstrate spatial control of the light-emitting zone in these devices.

Spatial control means users can control the location from where light emanates. In turn, this forecasts highly tunable lighting and displays. Spatially controlling LEC light entails controlling the position of the light-emitting p-n junction. When applying voltage, the p-n junction forms and causes ion movement towards the LEC electrodes, leading to p- and n-doped regions. Where the doped regions meet, the charge carriers recombine and emit light.

Magnus Berggren forecasts potential applications of spatial control that include controlling the color, assuming the distribution of different colors laterally along the area between the two electrodes. Berggren also predicts that LECs occupying a place alongside OLEDs in future lighting technology.

Producing LECs is another marvel to observe. Recently, Professor Ludvig Edman and PhD Andreas Sandström at Umeå University produced organic LECs using a roll-to-roll compatible process under ambient conditions (fig. 14). Executing all necessary steps, i.e., ink prep, coating of the constituent layers, and the final device operation under ambient air means LEC technology is viable for low-cost fabrication of large-area light emitting devices.

FIG. 14: LECs are producible using a low-cost roll-to-roll compatible process under ambient temperature conditions.

Beyond The Normal Fringe

Stated at the onset, LEDs and their derivatives thereof are certainly infiltrating virtually every electronic product and application. There’s no doubt LED lighting will squeeze incandescents and CCFLs into the nostalgia bin at some point. In the medical arena, LED lighting has become the accepted medium for exam and operating rooms.

Tuned light sources currently outfit numerous applications you may or may not hear about on any regular or irregular basis. For example, you’ll find tuned LED systems in an array of healthcare and alternative medical designs. Skin treatments, muscle healing, and tissue mending are just a few. Whether they are viable or successful is the topic of heated debates that are inappropriate here.

Regardless of external factors, LEDs are offering imaginative designers and developers numerous paths to innovation and profit. The yellow-brick road to that end is most likely illuminated with ruby red LEDs. However, in terms of general home, business, and automotive lighting, someday, hopefully, LED makers will get it right and create light that is actually useable. ~MD

RELATED STORIES:

LIVALL is the first smart and safe cycling helmet

Polar introduces Polar Loop 2 activity tracker

Global Quantum Dots Market to Witness 30.4% CAGR During 2015 – 2020

Graphene-based film can be used for efficient cooling of electronics