The measurement of electric current strength is not always easy, especially  when the measured signal requires further electronic conditioning. Simply connecting an ammeter to an electrical circuit and reading out the value is no longer enough. The current signal must be fed into a computer in which sensors convert current into a proportional voltage with minimal influence on the measured circuit. The basic sensor requirements are galvanic isolation and a high bandwidth, usually from DC up to at least 100 kHz. Conventional current measurement systems therefore tend to be physically large and technically complex.

when the measured signal requires further electronic conditioning. Simply connecting an ammeter to an electrical circuit and reading out the value is no longer enough. The current signal must be fed into a computer in which sensors convert current into a proportional voltage with minimal influence on the measured circuit. The basic sensor requirements are galvanic isolation and a high bandwidth, usually from DC up to at least 100 kHz. Conventional current measurement systems therefore tend to be physically large and technically complex.

Early Solutions

The oldest technique is to measure the voltage drop across a resistor placed in the current path. To minimize energy losses the resistor is kept very small, so the measured voltage must be highly amplified. The amplifiers offset voltage must be as small as possible and its supply voltage must be at the potential of the circuit, often 110 V mains (230 V in Europe) with high parasitic peaks from which its output must be isolated. This requirement increases overall system cost.

Another widespread principle is the transformer. Its construction is mu

ch simpler, but it doesnt allow the measurement of DC signals. Isolation between primary and secondary sides is implicitly given. A problem is the limited frequency range.

Figure 1. In a closed-loop Hall sensor, after the voltage is amplified the current flows through a compensation coil on the magnetic core. A magnetization is thus generated with the same amplitude as that of the primary current conductor but in the opposite direction. The result is that the magnetic flux in the core is compensated to zero [6].

Hall Current Sensors

Hall sensors also measure the magnetic field surrounding the conductor but, unlike current transformers, they also sense DC currents. A circular core of soft magnetic material is placed around the conductor to concentrate the field. The Hall element, which is placed in a small air gap, delivers a voltage that is proportional to the measured current. This sensor also offers a galvanic isolation.

The very small output voltage of the Hall element must be highly amplified, and the sensitivity is temperature dependent and requires adequate compensation. There is an inevitable offset, i.e., a small DC voltage at zero current; the offset amplitude and temperature coefficient are subject to significant fluctuations. The smaller the current to be measured, the higher the offset-induced relative error. Also of note is sensitivity to short current peaks in the circuit: according to the hysteresis properties of the core material, these peaks can cause a static magnetization in the core that results in a permanent remanence, and finally to an offset alteration of the Hall element.

Figure 2. Magnetoresistive field sensors are usually configured as a half or full bridge. The barber poles are positioned such that in the presence of a magnetic field the value of the first resistor increases and that of the second decreases.

The two types of Hall effect current sensor are open loop and closed loop. In the former, the amplified output signal of the Hall element is directly used as the measurement value. The linearity depends on that of the magnetic core. Offset and drift are determined by the Hall element and the amplifier. The price of these sensors is low, but so is their sensitivity.

Closed-loop Hall sensors are much more precise. The Hall voltage is first highly amplified, and the amplifiers output current then flows through a compensation coil on the magnetic core (see Figure 1). It generates a magnetization whose amplitude is the same but whose direction is opposite to that of the primary current conductor. The result is that the magnetic flux in the core is compensated to zero.

(The principle is similar to that of an op amp in inverter mode, for which the input voltage is always close to zero.)

The nonlinearity and temperature dependence of the Hall element are thus compensated but the offset remains. Closed-loop current sensors work up to frequencies of ~150 kHz. They are not cheap, though, and for high currents they become very bulky.

Magnetoresistive Field Sensors

|

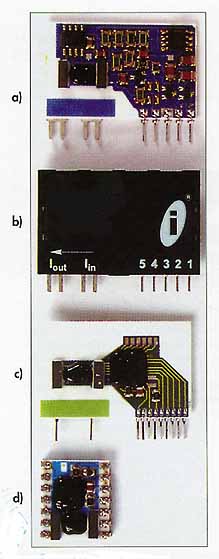

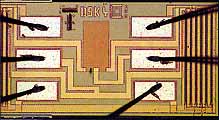

| Photo 1. Practical realizations of magnetoresistive current sensors include the opened hybrid circuit (A); the packaged standard element (B); a new ASIC sensor (C); and a dual in-line SMD component that can be used with different current conductors (D). |

Practical magnetic field sensors based on the magnetoresistive effect (see The Magnetoresistive Effect) are easily fabricated by means of thin film technologies with widths and lengths in the micrometer range. They have been in production for years in many different executions [1,2,3,4]. To reduce the temperature dependence, they are usually configured as a half or a full bridge. In one arm of the bridge, the barber poles are placed in opposite directions above the two magnetoresistors, so that in the presence of a magnetic field the value of the first resistor increases and the value of the second decreases (see Figure 2).

For best performance, these sensors must have a very good linearity between the meas uredquantity (magnetic field) and the output signal. Even when improved by the barber poles, the linearity of magnetoresistive (MR) sensors is not very high, so the compensation principle used on Hall sensors is also applied here. An electrically isolated aluminum compensation conductor is integrated on the same substrate above the permalloy resistors (see Figures 3 and 4). The current flowing through this conductor generates a magnetic field that exactly compensates that of the conductor to be measured. In this way the MR elements always work at the same operating point; their nonlinearity therefore becomes irrelevant. The temperature dependence is also almost completely eliminated. The current in the compensation conductor is strictly proportional to the measured amplitude of the field; the voltage drop across a resistor forms the electrical output signal.

Magnetoresistive sensors, as are Hall elements, are very well suited for the measurement of electric currents. In such applications it is important that external magnetic fields do not distort the measurement. This is achieved by forming a full bridge made of four MR resistors, where the two arms of the bridge are spatially separated. The barber poles have the same orientation in the two arms, so that only a field difference between the two positions is sensed. This configuration is insensitive to external homogeneous perturbation fields. The primary current conductor is U-shaped under the substrate, so that the magnetic fields acting on the two arms of the bridge have the same amplitude but opposite directions. This way the voltage signals of the two half-bridges are added.

The sensors have been in production for several years [5]. In the examples shown in Photo 1A, B, and C, a ceramic plate is used as the substrate, onto the back of which the primary conductor is glued to achieve an isolation of several kilovolts.

The sensors require neither a core nor a magnetic shielding, and can therefore be assembled in a very compact and cheap way. The have a linearity error of <0.1%, gain error <0.2%, offset voltage <10 mV, and temperature drift of the gain <100 ppm/K. The output signal is calibrated to 2.5 V at nominal

current by a laser trimming process or by a digital calibration. The rise time (10%90%) is ~1.7 ms, which corresponds to a frequency bandwidth (1 dB) >50 kHz; this value results from the speed of the regulation. The sensor is powered by a standard bipolar voltage of ±15 V and the power consumption is 320 mW to 640 mW, depending on the measured current value.

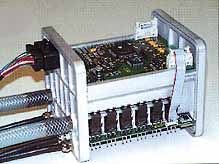

Photo 3. Three current sensors are shown here in a frequency inverter.

The size of the actual MR sensor chip with the four permalloy strips on silicon is 1 mm by 2 mm2, the distance between the two arms of the bridge being 1.6 mm (see Photo 2). It is mounted with the electronics on a 23 mm by 35 mm2 single in-line hybrid circuit designed for through-hole PCB mounting with very low profile. The NT-xx product family from Sensitec includes sensors for nominal currents of 5 A, 15 A, 25 A, and 50 A.

Figure 3. Magnetoresistive current sensors detect changes in magnetic fields but are insensitive to homogeneous fields. The orientation of the barber poles on the two arms of the bridge has been modified from the configuration shown in Figure 2.

Among the advantages of these sensors are:

Significantly smaller volume and weight compared to conventional current sensors, permitting greater flexibility in application-specific design

No remanence in the event of overload

Measurement of DC and AC currents without additional loss

Photo 2. The actual sensing element consists of magnetoresistive Permalloy strips integrated onto a silicon chip.

Wide frequency range due to low inductive design

No auxiliary supply necessary on the level of current to be measured

Low system costs

Initially developed for use in inverters (see Photo 3) and servo-regulators, MR current sensors have a broad range of other applications: energy distribution; power electronics systems such as inverters and mains receivers; battery management (charge and discharge currents); solar technology; electrical vehicles; uninterruptable power supplies; robotics; automotive (e.g, drive-by-wire); and safety devices.

The signal conditioning electronics of the NT-xx family is adiscrete circuit; in the new NTS-xx

family, it has been integrated into an ASIC operating at frequencies up to 100 kHz. The output signal is scalable to meet the requirements of external A/D converters. Additional functions are a comparator I/O with adjustable trigger level for short-circuit detection, an open-drain concept that permits three-phase monitoring, and a true rms output for power measurement and protection. These sensors are supplied with a unipolar voltage of +5 V, compatible with most digital interfaces. Since no core is used to concentrate the magnetic field, there is no remanence, which means that overcurrents produce no permanent offset changes. The compensation method guarantees a high linearity. The profile on the PCB board is low, and the mounting is very easy.

Figure 4. In this cross section of a magnetoresistive sensor with compensation, the isolated aluminum compensation conductor can be seen above the Permalloy strips and barber poles.

The ASIC allows digital calibration of the current measurement system even after installation in an application. The calibration data are stored on the chip. The MR sensor is located on a second chip. A co-integration of sensor and interface electronics on the same silicon substrate is possible but is not yet cost effective. The principal application areas will be in electronic systems for the automotive industry (see Current Sensors in Tomorrows Cars), motion control,

automation, or energy management in buildings.

Figure 5. The magnetic field lines and the position of the two sensing elements are shown in a cross section of a sensor capable of measuring a broad range of currents simply by adapting the geometry of the conductor.

In the standard sensor types described thus far, the nominal current is set by the geometry of the primary conductor that is part of the system and by the distance between the MR chip and the conductor. Recent investigations, however, have demonstrated that the high-current bus bar need not be interrupted or guided through a hole, as required with Hall transducers. Instead, it can simply be shaped in the form of a bus bar plate. A sensor module realized as a dual in-line surface mount device component can be mounted on the power PCB board placed above the bus bar plate so that the current flow can be directly measured.

A very clever and cost-effective solution for the measurement of high currents, especially in series applications, was presented at PCIM99 in Nuremberg, Germany, where it drew considerable attention. In this execution, the current is directly measured in the primary conductor (flat conductor,

PCB) and the sensor module is then simply clipped into a slot made in the conductor (see Photo 4). The result is a differential field measurement system that is insensitive to homogeneous external magnetic perturbations. The sensors and the ASIC are mounted on an appropriate substrate and encapsulated in a plastic package (see Figure 5). With this sensor, a broad range of currents can be measured simply by adapting the geometry of the conductor. Potentially heterogeneous perturbation fields can easily be shielded.The advantages are obvious: these current sensors are not only small, compact, and light, but also cheap and easy to mount. The primary current conductor can be part of the application and need not be mounted separately. This opens the way to completely new construction possibilities for developers of power electronic modules and devices such as for mains receivers and frequency inverters.

Photo 4. The latest type of magnetoresistive current sensor is placed into a slot in a straight conductor, in this case a 200 A copper bus bar.

Long before chip or even thin film technologies were developed, simple wires drawn of NiFe were known to possess an orientation of their magnetization, a magnetic moment, along their linear axes. Interestingly, it was found that changing the orientation of the magnetic moment in the wire caused a current passing through it to change correspondingly. The orientation could be changed by applying an external magnetic field, and generally an increase in current (i.e., a decrease in resistance) was observed. This phenomenon was called anisotropic magnetoresistive effect.

Today, the ferromagnetic materials can be deposited as thin films and structured into small strips that are typically 40 nm thick, 10 mm wide, and 100 mm long. A magnetic field is applied during the process. In modern device fabrication an alloy commonly called Permalloy (81% Ni, 19% Fe) turns out to be the best compromise in terms of device sensitivity, longevity, and reproducibility. In the most general case, the electrical resistance of AMR material depends on the angle, u, between the direction of the magnetization, M, and the direction of the current going through it. This dependency can be described by the relative change in resistivity, DR/R being proportional to cos2u. This means that when the current and magnetic moment, M, are parallel, the resistance of the strip is greatest; when they are at a 90° angle to each other, it is smallest. Disregarding the influence of film thickness, the maximum relative change in resistance is a material constant. In Permalloy it is typically 2%3%.

As can be deduced from Figure 6, the characteristics of a simple strip make it less than desirable for measurement applications. The reasons are that it exhibits a vanishing sensitivity at low fields; that the direction of the external field cannot be determined; and ex Adding small structures made of a highly conductive material such as aluminum to the strip creates a barber pole configuration. In the simplest case, barber poles are just tiny blocks of material sitting on top of the Permalloy. Their typical linear dimension in all directions is a couple of microns, and they are arranged at an angle of <45° to the long axis of the strip. Serving as local shorts for the Permalloy, they force the current to flow through it at that angle. Thus, an angle of 45° between current flow and magnetization, M, results when no external field is applied. This gives the barber pole device the desired maximum sensitivity at zero field and a corresponding linearity around the working point. Working at roughly an average value between maximum and minimum resistance of a simple strip, the barber pole device reacts in an unequivocal way to changes in the external field direction. In the majority of practical applications AMR sensor chips are composed of barber pole devices wired as Wheatstone bridges. AMR chips have significant advantages over other technologies such as Hall devices: They can be used at high frequencies (some MHz are no problem) and high temperatures such as those in automotive environments (continuous service at 150°C, peak values at 190°C), and exhibit low and stable offset values. Due to their high sensitivity (~10 3 that of Hall devices) they can be used to detect very weak fields (the present limit is ~10 nT). The anisotropic magnetoresistive effect (AMR effect) is known to be present in a whole family of ferromagnetic alloys. Most of these alloys are composed of iron (Fe), nickel (Ni), and chromium (Cr), and may be binary (two components) or ternary (three components). They have in common a more or less strong anisotropy in their magnetic properties. Whenever these materials are exposed to a magnetic field during crystal formation, a preferred orientation in magnetization will result. The same happens when the materials are forced into shape, i.e., a mechanical anisotropy is imposed. Long before chip or even thin film technologies were developed, simple wires drawn of NiFe were known to possess an orientation of their magnetization, a magnetic moment, along their linear axes. Interestingly, it was found that changing the orientation of the magnetic moment in the wire caused a current passing through it to change correspondingly. The orientation could be changed by applying an external magnetic field, and generally an increase in current (i.e., a decrease in resistance) was observed. This phenomenon was called anisotropic magnetoresistive effect. Today, the ferromagnetic materials can be deposited as thin films and structured into small strips that are typically 40 nm thick, 10 mm wide, and 100 mm long. A magnetic field is applied during the process. In modern device fabrication an alloy commonly called Permalloy (81% Ni, 19% Fe) turns out to be the best compromise in terms of device sensitivity, longevity, and reproducibility. In the most general case, the electrical resistance of AMR material depends on the angle, u, between the direction of the magnetization, M, and the direction of the current going through it. This dependency can be described by the relative change in resistivity, DR/R being proportional to cos2u. This means that when the current and magnetic moment, M, are parallel, the resistance of the strip is greatest; when they are at a 90° angle to each other, it is smallest. Disregarding the influence of film thickness, the maximum relative change in resistance is a material constant. In Permalloy it is typically 2%3%. As can be deduced from Figure 6, the characteristics of a simple strip make it less than desirable for measurement applications. The reasons are that it exhibits a vanishing sensitivity at low fields; that the direction of the external field cannot be determined; and except for the region around 45°, there is nearly no signal linearity. To make a usable device, a trick shown in Figure 7 is applied. Adding small structures made of a highly conductive material such as aluminum to the strip creates a barber pole configuration. In the simplest case, barber poles are just tiny blocks of material sitting on top of the Permalloy. Their typical linear dimension in all directions is a couple of microns, and they are arranged at an angle of <45° to the long axis of the strip. Serving as local shorts for the Permalloy, they force the current to flow through it at that angle. Thus, an angle of 45° between current flow and magnetization, M, results when no external field is applied. This gives the barber pole device the desired maximum sensitivity at zero field and a corresponding linearity around the working point. Working at roughly an average value between maximum and minimum resistance of a simple strip, the barber pole device reacts in an unequivocal way to changes in the external field direction. In the majority of practical applications AMR sensor chips are composed of barber pole devices wired as Wheatstone bridges. AMR chips have significant advantages over other technologies such as Hall devices: They can be used at high frequencies (some MHz are no problem) and high temperatures such as those in automotive environments (continuous service at 150°C, peak values at 190°C), and exhibit low and stable offset values. Due to their high sensitivity (~10 3 that of Hall devices) they can be used to detect very weak fields (the present limit is ~10 nT).The Magnetoresistive Effect

The anisotropic magnetoresistive effect (AMR effect) is known to be present in a whole family of ferromagnetic alloys. Most of these alloys are composed of iron (Fe), nickel (Ni), and chromium (Cr), and may be binary (two components) or ternary (three components). They have in common a more or less strong anisotropy in their magnetic properties. Whenever these materials are exposed to a magnetic field during crystal formation, a preferred orientation in magnetization will result. The same happens when the materials are forced into shape, i.e., a mechanical anisotropy is imposed.

Figure 6. The Permalloy strip has an orientation of the inner magnetic moment, M0, parallel to its long axis. When an external field is applied, the total magnetization of the strip is turned at an angle, u.

Figure 6 shows the position of a Permalloy strip. As does the wire, the strip has an orientation of the inner magnetic moment, M0, parallel to its long axis. When an external field is applied, the total magnetization, M, of the strip is turned at an angle, f.

Figure 7. To detect the direction of an external magnetic field, the Permalloy strip is augmented with small structures made of a highly conductive material to create a barber pole configuration.

cept for the region around 45°, there is nearly no signal linearity. To make a usable device, a trick shown in Figure 7 is applied.

This change, though, would overload the conventional 12 V car generators and batteries. Rather than increasing the current and corresponding cable cross-sections, it makes more sense to make 42 V the future standard. One immediate consequence will be a combined starter-generator placed directly on the crankshaft. Prototypes of this unit were presented by Mannesmann-Sachs AG at the 1999 IAA car exhibition in Frankfurt, Germany. The unit is a three-phase synchronous engine using a permanent excitation. It is integrated into the flywheel of the clutch and can be used as either a starter or a generator. Efficiency is increased significantly in both modes of operation. On one hand, the engine is started at a higher starter speed, and on the other, the new generator will produce much more electric power without increasing power demand on the combustion engine. Very effective start/stop systems can thus be realized: The engine is switched off whenever the vehicle stops and started again automatically when the driver wants to go on. These measures should lead to fuel savings of around 30% compared to todays vehicles. A prototype of the starter-generator control unit made by Mannesmann-Sachs (see Photo 5), requires the use of three-phase MOSFET alternators. For control and safety reasons, these alternators need current sensors for at least two of these phases. Mannesmann uses a customer-specific version of Sensitecs NTS-xx system, in this case an NTS-xx hybrid without a

The conductor in Photo 6 is configured as a 0.8-mm-thick copper bus bar. At the location of the NTS-xx, the bar takes a U-shaped configuration to generate the necessary magnetic field gradient. For this application, the NTS-xx is mounted directly above the bar and electronically calibrated in situ. This arrangement has many advantages. Production is much easier because there is no need to break or disconnect the conductor carrying the working current or even feeding it through the NTS-xx itself. Furthermore, because this version of the NTS-xx can be used for practically all measurement ranges (e.g., 10 A, 100 A, or 1000 A), provided the busbar is adapted correspondingly, a great reduction in manufacturing cost can be realized. Fuel efficiency firstthis is the present motto of automotive development worldwide. Not only the combustion engine, but all other automobile components as well are being optimized to achieve this goal. Many components that are at present powered by the cars engine will in the near future operate on electricityair conditioning compressors, water pumps, oil pumps, and the like. Due to continuously changing engine speed, these components have rather poor efficiency ratings. Electric motors have the capability of optimizing their operation, independent of engine speed. This change, though, would overload the conventional 12 V car generators and batteries. Rather than increasing the current and corresponding cable cross-sections, it makes more sense to make 42 V the future standard. One immediate consequence will be a combined starter-generator placed directly on the crankshaft.

Prototypes of this unit were presented by Mannesmann-Sachs AG at the 1999 IAA car exhibition in Frankfurt, Germany. The unit is a three-phase synchronous engine using a permanent excitation. It is integrated into the flywheel of the clutch and can be used as either a starter or a generator. Efficiency is increased significantly in both modes of operation. On one hand, the engine is started at a higher starter speed, and on the other, the new generator will produce much more electric power without increasing power demand on the combustion engine. Very effective start/stop systems can thus be realized: The engine is switched off whenever the vehicle stops and started again automatically when the driver wants to go on. These measures should lead to fuel savings of around 30% compared to todays vehicles. A prototype of the starter-generator control unit made by Mannesmann-Sachs (see Photo 5), requires the use of three-phase MOSFET alternators. For control and safety reasons, these alternators need current sensors for at least two of these phases. Mannesmann uses a customer-specific version of Sensitecs NTS-xx system, in this case an NTS-xx hybrid without a conductor for the working current. The conductor in Photo 6 is configured as a 0.8-mm-thick copper bus bar. At the location of the NTS-xx, the bar takes a U-shaped configuration to generate the necessary magnetic field gradient. For this application, the NTS-xx is mounted directly above the bar and electronically calibrated in situ. This arrangement has many advantages. Production is much easier because there is no need to break or disconnect the conductor carrying the working current or even feeding it through the NTS-xx itself. Furthermore, because this version of the NTS-xx can be used for practically all measurement ranges (e.g., 10 A, 100 A, or 1000 A), provided the busbar is adapted correspondingly, a great reduction in manufacturing cost can be realized.Current Sensors in Tomorrows Cars

Fuel efficiency firstthis is the present motto of automotive development worldwide. Not only the combustion engine, but all other automobile components as well are being optimized to achieve this goal. Many components that are at present powered by the cars engine will in the near future operate on electricityair conditioning compressors, water pumps, oil pumps, and the like. Due to continuously changing engine speed, these components have rather poor efficiency ratings. Electric motors have the capability of optimizing their operation, independent of engine speed.

conductor for the working current.

Photo 5. A three-phase alternator designed for an automotive starter-generation was introduced in prototype in 1999.

Photo 6. An application-specific NTS-xx sensor features a conductor configured as a copper bus bar.

References

1. H. Lemme. 1998. Magnetfeld-Sen soren-vielseitige Helfer, Elektronik, H.3, S.40.

2. A. Petersen. 1985. Magnetoresistive Sen soren im Kfz, Elektronik, H.10, S.99102.

3. G. Reiniger. 1986. Drehwinkel mes sung mit Magnetfeldsensoren, Elektronik, H.23, S.129.

4. E. Dettmann and V. Loreit. 1997. Center Assembly for Measuring Current as a Function of Magnetic Field Gradients. U.S. Patent No. 5,621,377.

5. J. Rühl and T. Walther. 1993. Strom sensor als Mikrosystem, Elektronik, H.20, S.42.

6. W. Göpel et al. 1989. SensorsA Comprehensive Survey, VCH-Verlag. Weinheim.