Piezoelectric transducers are based on electro-ceramic materials that convert mechanical power into electrical power and vice versa. There are two effects: when a force is applied, an electric charge is generated (direct piezo effect), and when an electric field is applied a dimensional change occurs (inverse piezo effect). While the inverse piezo effect can be used for motion control applications, the direct piezo effect or a combination of both effects lends itself to the manufacture of sensors.

No Wear

The piezo effect is based exclusively on displacements within the crystal lattice of the piezoelectric element and not subject to any mechanical friction or wear. It is also highly sensitive – the smallest deformations produce a measurable charge displacement, and potential changes as small as microvolts can produce sub-nanometric motion – after all, atomic force microscopes use the piezo effect. This opens up a multitude of potential applications, including ultrasonic, force or acceleration sensors, and complex adaptive systems.

Generating and detecting ultrasound, for example, is a classic piezo application because AC voltages make piezo elements oscillate. Oscillation frequencies of up to 20 MHz are feasible. Ultrasound is sound above the human hearing range, typically starting with frequencies above 20 kHz. This frequency range is used for many purposes in industry, medical engineering and research. Ultrasonic piezo transducer applications include distance measurement, object recognition, filling level or flow measurements, high-resolution material tests, and medical diagnosis and therapy.

Flexibility in Frequency and Geometry

In order to adapt the transducers to different applications, manufacturers need to be able to modify the piezo formulation and mechanical design – starting with the piezo powder, and maintaining full control over all manufacturing steps, allowing for fully customized components, assemblies and systems. There are two basic classifications: sensor applications for frequencies of up to 20 MHz, and power ultrasound with much higher energy densities.

With power ultrasound, the piezo elements carry out considerable mechanical work – they crush kidney stones, for example or remove plaque, provide the mechanical energy for ultrasonic cleaning baths, as well as for industrial welding and bonding. The typical frequencies of power ultrasound are between 20 and 3,000 kHz.

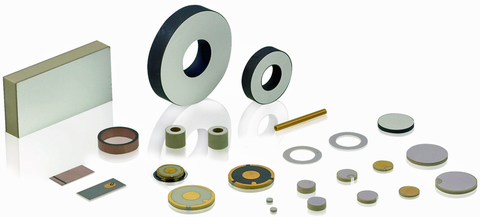

A great variety of geometries and resonant frequencies can be realized, in addition to the material selection, for the respective application (Fig. 1). To work efficiently for an OEM, standard components such as piezoceramic rings, piezo tubes and shear elements need to be stocked or made available on very short notice on the basis of semi-finished products.

To measure the flow, filling level, and force or acceleration, customized sensor components need to be easily integrated in the respective application.

Level Measurement

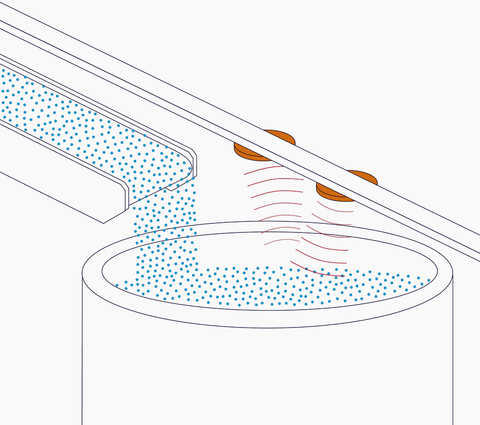

A common application of ultrasonic piezo transducers is the measurement of filling levels (Fig. 2). Here, the ultrasonic delay measurement makes use of both the direct and inverse piezo effect. The piezo transducer is placed outside of the medium to be detected and works as a transmitter and receiver. It emits an ultrasonic pulse that is reflected by the filling medium. The propagation time is a measure of the distance travelled in the empty part of the container and inversely proportional to the filling level. This principle allows non-contact measurements for both liquids and solids, for example, in food or material silos. The accuracy depends on the reflectivity of the respective surface.

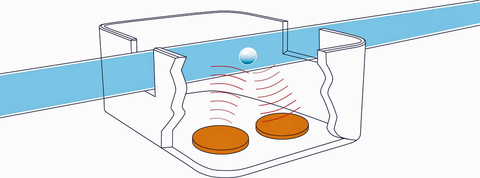

Piezo elements placed at different heights in submersible transducers or tuning-fork sensors can also be used as level switches in containers (Fig. 3). The piezo transducers excite a tuning fork at its natural frequency.

When it comes into contact with the medium, the resulting shift in the resonant frequency is detected by an electronic circuit. This method is very reliable and completely independent of the type of filling medium.

Air Bubble Detection and Flow Measurement

In monitoring dosing and filling systems, it is often necessary to ensure an undisturbed flow without air or gas bubbles. This is especially important in highly sensitive medical applications such as dialysis or blood transfusions. This is achieved with ultrasonic bubble detectors. The piezo elements in these sensors serve to generate and detect ultrasonic waves. The sensors are mounted on the outside of tubes and operate without contact to the transported medium. There is no interference with the flow rate, nor is there any danger of contamination.

Similar advantages are found with flow measurement. This is based on the time difference during the alternate transmission and reception of ultrasonic pulses in and against the flow direction (Fig. 4).

reception of ultrasonic pulses in the direction of flow and in the opposite direction.

Here, two piezo transducers operating as both transmitter and receiver are arranged diagonally to the direction of flow. When using the principles of the Doppler effect, the phase and frequency shift of the ultrasonic waves which are scattered or reflected by liquid particles are evaluated. The frequency shift between the reflected wave, front-emitted, and received by the same piezo transducer is proportional to the flow speed.

Acceleration Sensors

Piezoelectric acceleration sensors operate at lower frequencies than most ultrasonic transducers. At their heart is a piezo element that is connected to an inert seismic mass. When acceleration occurs, the inert mass amplifies the mechanical deformation of the piezo disc increasing the measurable electric voltage created by the piezo effect.

These highly dynamic sensors detect accelerations in a broad frequency range with a nearly linear characteristic over the complete measurement range. They provide high resolution and are available for tensile, pressure, and shear forces.

Adaptive Systems Technology

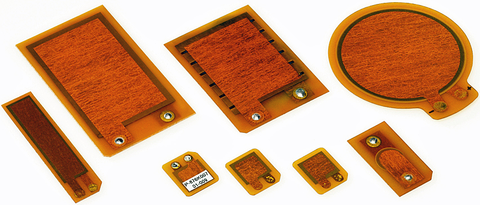

With the DuraAct patch transducer (Fig. 5), developed by Physik Instrumente (PI), a very versatile piezoelectric device is now commercially available that finds applications in industry and research. The thin, lightweight transducers can be integrated into a structure or simply just be glued to a surface. A special manufacturing method makes the ceramic extremely bendable, which allows it to be attached to moving structures, where it gets deformed and thereby generates charge transfers.

In adaptive systems technology, the bendable transducer is used as both sensor and actuator. These systems measure interfering vibrations and compensate them at the same time. Another application – structural health monitoring – involves generating vibrations and measuring their propagation through solid structures. A changed vibrational pattern shows failures in the structure even before fissures arise, for example in machine parts, bridges, and aircraft wings.

At the heart of the transducer is a piezoceramic film with an electrically conductive layer applied to each side. This construction is then embedded in a flexible polymer strip. The advantages of this design are multiple: the piezoceramic is electrically insulated, mechanically preloaded, and, out of the basically brittle ceramic, a unit is created which is so robust that it can be affixed to surfaces with bending radii as low as 20 mm (Fig. 6).

Transducers for Hydroacoustics and Sonar

Sonar (sound navigation and ranging) is the maritime counterpart to radar; however, it replaces radio waves with sound waves – which explain why it is sometimes also called echo sounder. High-power piezo transducers are used here to generate the ultrasonic sound waves, which bounce off of fish, objects, vessels, or the bottom of the ocean. Again, electronics convert the delayed signals into information such as distance, size and shape. In addition to measuring applications, hydroacoustic piezo transducers can also be used for underwater communication. A diverse range of piezoelectric elements is used here, with compact disks or plates at the lower end of the spectrum, and stacked piezo ceramics and complete arrays of transducers for high-end applications.

for sonar applications.

Versatility

Piezoceramic transducers, used in ultrasonic sensor and power applications, have become increasingly important for implementing critical mechanical operations, such as in medical engineering, welding, and flow and level measurement. They have proven their versatility in a broad spectrum of applications. As piezo research expands the shapes, dimensions, capabilities and product offerings of piezo components, so will continue to expand the opportunities for piezo ultrasonic use in diverse industries.

About the authors

Frank Moeller is sales manager at PI Ceramic, in Lederhose, Germany. He holds an MS in physics and has 25 years of experience with piezo ceramics manufacturing and electro ceramics applications.

Stefan Vorndran is VP of marketing and tactical engineering at PI (Physik Instrumente) LP. He holds an MS in EE and brings with him over 25 years of experience with nanopositioning and piezo motion applications.