Thin-film interference coatings have been used in commercial optical systems since the 1930s for purposes ranging from antireflection coatings to bandpass filters. Created by stacking transparent films of different refractive index materials to create specific reflectance or transmission properties, such coatings, in most cases, have been designed with fixed characteristics. Only recently has a practical technology emerged to create tunable versions of thin-film filters, and this gives rise to a host of applications not only for communications but also for many types of sensors.

The boom in wavelength division multiplexed (WDM) fiber-optic networks in the late 1990s spurred the need for low-cost tunable filters. WDM involves the presence of multiple closely spaced wavelengths of light on a single fiber and so it created a need for tunable optical components. One of the main methods used to make fiber-compatible tunable filters is the MEMS Fabry-Perot approach where two micromachined mirrors are separated by a variable spacer or cavity. A Fabry-Perot filter is limited by its inflexible spectral bandpass shape, a pointed narrow transmission peak with wide sloping skirts shown in Figure 1.

Figure 1. Multicavity thin-film filters have more flexible spectral profiles than that of the simple Fabry-Perot filter shown in this diagram. |

Thin-film multicavity designs, on the other hand, with their more complex alternation of spacers and mirrors, are capable of more varied spectral shapes, including flat-top filters with steep sides or transmission bandpass shapes matched to a specific target spectrum. However, adding tunability to these complex designs appeared impractical for many years because the materials and thin-film deposition techniques in common use were only weakly tunable.

A new thin-film filter technology has emerged that combines strong tunability with the full flexibility of sophisticated multilayer, multicavity thin-film designs. The trick is to include layers of highly temperature-sensitive semiconductor films, such as amorphous silicon or germanium, in the film stack. The resulting filters can then be thermo-optically tuned by internal heater films. Aegis Semiconductor pioneered the development of thermo-optically tunable filters, at first for the telecom industry and more recently for other center wavelengths from 0.8-12.0 µm with tunability of up to 4% of center wavelength.

This device family has now been engineered to meet stringent telecom industry qualification standards including service lifetimes of 20 years at 10 scans/s. This is remarkable robustness in a device technology that calls for cycling microscopic volumes of thin films through hundreds of degrees of temperature change without peeling, cracking, or other failure mechanisms.

Beyond Telecom

Thin-film filters using amorphous silicon are inexpensive to manufacture and are deposited using plasma-enhanced chemical vapor deposition; each wafer yields thousands of filters (see Figure 2).

Figure 2. Thermo-optic thin-film filters are manufactured and tested on a wafer scale using techniques similar to those used to make flat panel displays. |

Recently, Aegis has succeeded in extending tunable filter technology from the telecom band at 1.5 µm to mid-IR wavelengths of 3-12 µm by augmenting amorphous silicon with germanium thin films. This spectral range includes many commercially and environmentally important trace gases, including carbon monoxide, carbon dioxide, methane, sulfur dioxide, nitrogen oxides, and refrigerants.

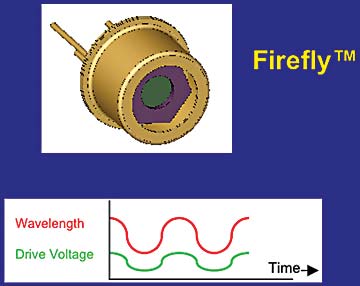

Trace Gas Sensors. Thermo-optic thin-film filters are not tunable over big swaths of spectrum as in conventional spectroscopy. Their key property may be better described as "wavelength-modulated" or "microtunable" filtering over a range of ~4% of center wavelength. For example, a narrow-band filter designed for the carbon monoxide absorption band at 4.7 µm can be tuned over about 4.6-4.8 µm, with millisecond speeds, fast enough to enable advanced signal processing methods such as lock-in detection. The filter can be integrated into a package with a blackbody IR emitter to produce a very narrow-band IR source whose output can be rapidly wavelength-modulated to sense whether carbon monoxide is present in an absorption path, and in what concentration. Using this technique (see Figure 3), Aegis demonstrated a carbon monoxide sensor module able to detect 10 ppm of carbon monoxide (the toxic limit is generally considered to be 50 ppm).

Figure 3. A wavelength-modulated IR emitter scans in a narrow range near the carbon monoxide absorption band for high-precision detection. |

Using the sample principle, a microtunable narrow-band emitter can also be applied to the detection of many other gas or chemical species (see Figure 4).

Figure 4. The microtunable filter integrated with a modulated blackbody is packaged in a TO5 can as a low-cost alternative to a tunable laser. |

Aegis has named this device family Firefly.

Optical scientists know that a tunable laser represents the most sensitive technique for detecting minute quantities of a trace gas. A microtunable emitter based on thermo-optic thin films operates in an analogous mode, but at 1/1000th the cost.

Raman Sensors. Another potential application of the microtunable filter may be as a family of Raman sensors to detect specific liquids or solids with high precision. Raman spectroscopy is a method for detecting the spectral features of chemicals by working in the more convenient visible or near-IR rather than the mid- or far-IR region of the spectrum. It uses the frequency shifts known as "Raman shifts" experienced by a laser beam when it is scattered by a solid or liquid. The information that comes from analyzing Raman-shifted laser light is widely used for chemical fingerprinting over the range of 300-3000 wave numbers, but usually requires high-performance, high-cost laser sources. For this reason even portable Raman instruments typically cost at least $20,000. A Raman sensor, on the other hand, requires only an inexpensive laser (such as those used in CD burners) and scans over a narrow band of Raman shifts-enough to measure the ratio of two molecular components, such as ethyl alcohol versus isopropyl alcohol. This type of sensor can be distributed in large numbers over a physical or wireless network for industrial process control or homeland security.

Temperature Sensors. Other applications of microtunable filter sensors exploit their sensitive response to temperature variations, allowing them to function as remote optical thermometers over a 25°C-500°C temperature range. It is also possible to form 2D arrays of microtunable filters whose individual size might be only 50 µm. These arrays show promise as uncooled thermal imagers more sensitive than microbolometers and they may have a role to play in sensing flow or acceleration or in biochemical reaction monitoring.

Looking to the Future

As the sensor industry moves to integrate new levels of intelligence into homes, power grids, automobiles, factories, homeland defense, and military systems through distributed, optical, or wireless networks, there is increasing demand for next-generation multipurpose sensors that are compact, low cost, rugged, and very reliable. Microtunable thin-film filters-manufactured and packaged inexpensively-bring optical sensing to a new level of simplicity that will match these needs.