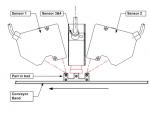

Duhamel DTI’s bench for testing magnetic circuits of electrical contactors employs the LJ-G Series 2D laser displacement sensor by Keyence. The system tests 4,000 to 5,000 parts per hour with a 1-micron level accuracy. A conventional method consists of using ultrasonic sensors that require measurements to be taken in an oil bath, which is cumbersome at the desired speeds. In addition, it entails many adjustments that impair the clarity and stability of the measurements. Duhamel DTI’s concept consists of using four LJ-G sensors to obtain four measurement lines that are used to derive four measurement segments for inspecting the poles and four measurement segments for inspecting the pole gaps. Each resulting contactor profile consists of 500 measurement points that are used to model flatness with the least-squares method. All measurements are compared against a master profile recorded beforehand in the system. The LJ-G5000 is a 2D laser displacement sensor. It features a unique E3-CMOS (Enhanced Eye Emulation CMOS) sensor that has a dynamic range that is 300 times wider than that of conventional sensors. For more details, visit http://www.keyence.com/dti

Keyence Corporation of America

Itasca, IL

888-539-3623

http://www.keyence.com

Contact Info