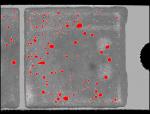

The C-SAM model DF2400Z acoustic micro imaging system automatically images and analyzes IGBT module defects. It employs the company’s inverted transducer, placed beneath the module to prevent water from reaching module circuitry. Once a routine for scanning has been defined, the factory automation interface controls the operation step by step as follows:

1. A conveyor loads two IGBT modules onto the two (for high throughput) system stages.

2. The two ultrasonic transducers, one for each stage, raster-scan each module. Ultrasound is pulsed into the module and echo signals are received from gap-type defects at the depths of interest.

3. At the conclusion of scanning, accepts and rejects are stacked in separate locations.

Accept/reject criteria are also written by the user of the system.

Sonoscan Inc.

Elk Grove Village, IL

847-437-6400

[email protected]

http://www.sonoscan.com

Contact Info