Introduction: The Spread of Connected Devices and Sensing

Technology advancements have made it possible to enable connectivity between many different types of devices. What began as a connected smartphone has evolved into a network of connected thermostats, appliances, vehicles and other devices which is referred to the internet of things (IoT). The IoT is comprised of numerous devices transmitting data back and forth through various interfaces, with a wireless cloud interface being the most common interface. As the number of connected devices continues to grow, the demand for more data also grows.

Data is generated through multiple sources, and electronic sensors are typically used to collect data from connected devices. A sensor is a device that translates a physical or environmental characteristic such as temperature and to an electrical signal.

Demand for data has driven growth in markets for sensors of numerous types, such as temperature, humidity, pressure, and proximity sensors to feed the systems with the data they need to work on. As the IoT now brings unprecedented moisture power to crunch data gathered through vast numbers of channels, electronic sensors are set to become even more pervasive. The global sensors market is expected to exceed $38 billion by 2022, according to research by Markets and Markets. The quest to capture more sensor data from more locations will also drive the development of new types of sensors that are smaller, lower power, lower cost, and easy to deploy in large numbers and in tiny spaces.

Electronic Sensor Architecture

Traditional electronic sensors include the same functional blocks, regardless of the specific design of the sensor. The core block of a sensor is the actual sensing element. The sensing element is the portion of the sensor that responds to the sensor environment and translates an environmental condition into an electrical parameter. In addition to the sensing element, sensors require power for the electronic components within the sensor and circuitry for data processing and connectivity.

Most electronic sensors include the sensing element, power block, and data processing block in each sensing node. As the demand for additional sense data increases, the cost to scale to multiple sense nodes becomes a cost barrier for some applications. The physical size of the components necessary for the sensor power and communication blocks restrict the options for small form factor sensors, and the maintenance and environmental concerns associated with battery power sensors also limit the deployment of sensors in some applications. The cost and size of traditional electronic sensors present barriers to scaling sensor networks, or deploying multi-sensor systems or disposable sensors as smart sensing and the IoT spread further into the world.

An alternative approach is needed, that can ideally eliminate reliance on bulky and expensive batteries, MCUs and associated circuitry. Recognizing that many connected sensors spend most of their time in standby or sleep modes to prolong battery life, power and intelligence are only needed during the short and infrequent periods when the sensor wakes to exchange small packets of data with the host system. If sensors could be powered temporarily from an external source, and the bulk of the data processing handled externally as well, these could enable cost-effective scaling of sensor networks and allow multi-sensing or innovations such as disposable sensors to become economically viable.

There is a technology that can provide a solution: Wireless passive sensors can already be loaded with memory, interrogated or over-written using a wireless reader and are activated by energy contained in the reader’s transmitted RF field. Legacy RFID communication standards are proven and robust, and provide a strong platform for the development of a new category of smart passive sensors that separate the sensing function from the power and control circuitry required with traditional electronic sensors.

Smart Passive Sensors

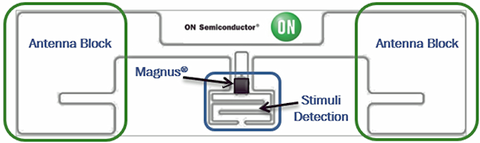

Smart passive sensors can unleash more of the potential of RFID technologies and standards to support convenient and energy-efficient wireless data exchange. By integrating a printed antenna and stimulus-detection loop with an RF IC designed to fulfill the function of a passive sensor tag. Figure 1 shows the key functional elements of a smart passive sensor, comprising the antenna, stimuli detector, and sensor-block control IC.

The smart passive sensor communicates using the industry-standard UHF Gen 2 protocol, and can be read using a suitable RFID reader. Several commercially available readers in fixed or handheld formats have been tested with the tags and their functionality verified. ON Semiconductor’s smart passive sensor ecosystem provides a portable battery-powered reader with built-in antenna, graphical user interface and IoT connectivity, which can be used as a hub to collect data from sensor tags.

When the reader initiates communication, the self-tuning sensor IC detects moisture or pressure by measuring impedance changes in the stimuli loop, and transmits this data, as well as digitized temperature data from the on-chip temperature sensor, to the reader. The sensor monitors several parameters, including received signal strength (RSSI) to detecting proximity, motion or presence, temperature, and moisture. Each sensor also has a programmable EPC code for unique identification. The RFID front end automatically compensates for changes in the environment to sense moisture, pressure, and other parameters.

Typical Applications

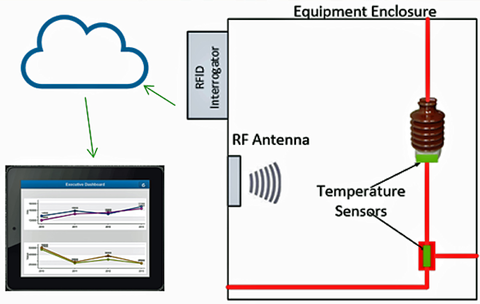

A wide variety of important applications can benefit from the availability of low-cost or disposable passive sensors. Monitoring temperatures at multiple locations inside datacenter server racks or on high power circuit breaker connections within industrial power switchgear, for example, can monitor temperature trends and quickly detect evidence of unusually elevated temperatures that may indicate a need for preventative maintenance or corrective action. Smart passive sensors attached directly to parts such as a metal enclosure, component packages or heatsinks can respond to periodic interrogation by a reader positioned within RF range of all the sensors.

Figure 2 presents a monitoring strategy based on smart passive sensors and an RFID reader/interrogator connected to the Cloud. This can provide a more immediate and cost-effective means of protecting equipment than other approaches such as manual temperature measurement or thermal imaging.

Passive smart sensor tags are also suited to digital farming applications, such as livestock monitoring to check for diseases or verify ovulation cycles. Farmers have used RFID tags successfully for simple purposes such as animal identification and tracking, and Industry standards for injectable tags are well established. Smart passives sensors now give the opportunity to further improve animal well-being and increase farming yield in breeding stock with incremental investment in equipment or systems.

Similarly, moisture or pressure detection using smart passive sensors has applications in scenarios such as healthcare, industrial testing, and automotive comfort and safety. In healthcare, for example, moisture sensors can be unobtrusively attached to hospital bed linen to detect patient occupancy and restfulness, and non-invasive temperature sensors can be attached to a patient’s skin (see figure 3) and monitored wirelessly using a nearby reader.

Further applications include water leak testing in the automotive industry: an array of smart passive moisture sensors can be installed quickly and efficiently in a vehicle before leak testing begins, and can eliminate labor-intensive manual probing, while also simplifying data collection and analysis.

Also, moisture and pressure sensing, with additional proximity sensing to detect seatbelt status, can enable more intelligent vehicle-occupancy detection than traditional in-seat wired or bladder systems can achieve. Smart passive sensors allow differentiation between a human occupant and an object simply placed on the seat, and sensing can be scaled easily at minimal extra cost to cover rear passenger seats and removable seats.

Smart passive sensor tags can be used for many other leak-detection, occupancy-sensing, and temperature or moisture-level monitoring duties in numerous applications from home automation and the connected car, to industrial controls, quality testing, agriculture, healthcare, construction, supply-chain management, and more.

Conclusion

Smart passive sensors introduce new options for ubiquitous sensing. Pressure, temperature, moisture or proximity can be monitored, eliminating bulk, power consumption and cost concerns that are associated with conventional smart sensors. Equipment designers can now extend the power of smart systems and the IoT into areas and applications that have historically been inaccessible, whether due to size constraints or economic barriers.

About the author

Greg Rice is the Technical Marketing Manager for ON Semiconductor’s Business Unit. He has more than 20 years experience within the semiconductor industry, with a focus on high speed analog and RF products. Greg has held positions in design, product engineering, applications engineering, and now Technical Marketing Management. At ON Semiconductor, he is currently working to bring to market a new Smart Passive Sensor technology that has the potential to revolutionize the sensor industry.