In last month's article, "On-Site Trace Chemical Detection, Part 1: Understanding Ion Mobility and Differential Ion Mobility Spectroscopy", we covered the basics of traditional ion mobility spectroscopy (IMS) and the new differential mobility spectroscopy (DMS) and the reasons for the success of each technology. This article will cover these two discrete mobility spectroscopy technologies when integrated as a system.

First, let's begin with a quick review. Why do threat detection applications rely on mobility spectroscopy technologies? Because IMS and DMS offer the greatest sensitivity with the fastest detection time in comparison to any other detection technology used today for threat detection. In simple terms, IMS and DMS save lives in life-and-death situations by giving quick, actionable information. Although another technology can provide definitive data, the cost for this is time. Today, the U.S., U.K., and German governments all use IMS and DMS, in next-generation instruments, to protect people in the field by measuring the concentration of chemical warfare agents (CWAs), toxic industrial chemicals (TICs), toxic industrial materials (TIMs), explosives, and other chemicals.

A Brief Technology Review

I believe, as do many of Sionex's research and development people, that IMS and DMS are complementary technologies. IMS measures the time it takes a certain chemical ion to move through a uniform, low DC electric field. In theory, this is represented by Equation 1:

| (1) |

where:

| υi | = | Velocity (IMS determines time as velocity = distance/time) for chemical ion i to move through a uniform, low DC electric field |

| Ki | = | Coefficient of mobility of ion species i |

| E | = | Electric field strength |

This means that the velocity of a specific ion species is based on the coefficient of mobility of an ion in a given low electric field multiplied by the electric field strength. DMS identifies and detects chemicals based upon the chemical species' ion mobility in both low and high electric fields. Whereas IMS measures the ion's velocity in a given electric field, DMS measures its change of velocity (mobility) when exposed to low and high electric fields. DMS distinguishes one chemical species from another based on the target ion's overall change in movement, or distance traveled, when exposed to the different electric fields. This is represented by Equations 2 and 3:

| (2) |

| (3) |

where:

| υdown | = | Velocity for chemical ion i to move through a uniform, low electric field |

| υup | = | Velocity for chemical ion i to move through a uniform, high electric field |

| Kdown | = | Coefficient of mobility of ion species i, low electric field |

| Kup | = | Coefficient of mobility of ion species i, high electric field |

| Emin | = | Electric field strength, low electric field |

| Emax | = | Electric field strength, high electric field |

DMS measures the change in mobility (Δs, where s is distance), so we know that Equation 4 represents a given time.

| (4) |

where:

| si | = | Distance |

| ti | = | Time |

Therefore Equation 5 holds true:

|

(5) |

This change over time, between up and down cycles, is also known as an alpha parameter (αi). The αi is unique to each chemical species.

IMS and DMS theoretically are complementary. Consider Equation 6, the determination of the comprehensive coefficient of mobility (K(E)) of an ion species, which is an analytical fingerprint used for ion identification:

| (6) |

where:

| Ki(E) | = | Comprehensive coefficient of mobility of ion species i |

As you can see in Equation 6, Ki[E ~ 0] is an attribute of IMS and [1+αi(E)] is an attribute of DMS.

Therefore, to summarize:

- IMS and DMS should be considered as complementary methods

- IMS operation is based on the ion coefficient of mobility (Ki[E ~ 0])

- DMS operation is based upon the ion alpha parameter ([1+αi(E)])

- Combining IMS and DMS techniques enables determination of the comprehensive coefficient of mobility (K(E)).

Designing a Hybrid Detector

What would a hybrid DMS/IMS detector look like? Let's review some of the pros and cons of each technology. IMS uses a discrete pulsed flow and consequently uses only 1%–2% of the available ions while DMS uses a continuous flow and uses 80%–90% of the available ions. IMS is mono-polar and uses sequential polarity switching to see both positive and negative ions while DMS sees both positive and negative ions simultaneously. As a result, there is a benefit to using first DMS and then IMS. Because DMS generates both positive and negative ions simultaneously, we use two discrete IMS flow chambers, one of which has a positive polarity and the other has a negative polarity. A schematic of Sionex's DMS/IMS2 is shown in Figure 1.

Figure 1. A schematic of the hybrid DMS/IMS2 detector |

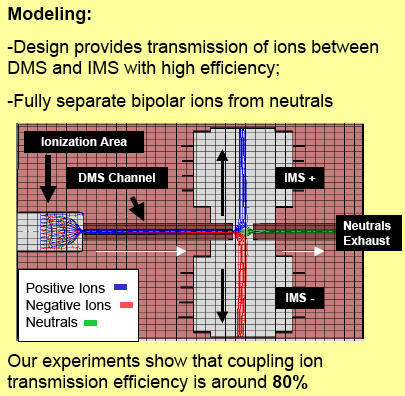

The design is optimized using the company's proprietary microDMx modeling software. In ion modeling studies (Figure 2) of the Sionex DMS/IMS2 detector we see that the design takes advantage of DMS's continuous sample flow, achieves complete bipolar separation from neutral species, provides ~80% ion transmission efficiency for each polarity. The tandem IMS detectors get a prefiltered, neutral-free sample of DMS-selected ions, resulting in greater sensitivity. Furthermore, by using Sionex-designed microelectromechanical systems (MEMS) technology, we can shrink the length of the IMS drift tubes to roughly 15 mm.

Figure 2. Results of software modeling showing the paths followed by negative and positive ions and neutral species |

To explore the benefits derived from this hybrid system, we can look at some sample data. IMS-based gas analyzers are deployed to detect trace levels of CWA and explosives because of their excellent sensitivity and relatively good selectivity. They can also operate at ambient pressure, making them suitable for field deployment. As the number of terrorist threats increases, these threat detection technologies are more widely

Figure 3. A two-dimensional ion plot shows the presence of nerve agent stimulant in air |

Stand-alone IMS and DMS systems provide one-dimensional data whereas the hybrid DMS-IMS detector provides two-dimensional data. Consider the detection of a nerve agent stimulant, dimethyl methylphosphonate (DMMP). Figure 3 shows a two-dimensional DMS-IMS topographic positive ion plot for 5 ppb DMMP in air. In the tandem system, the DMS provides compensation voltage (Vc) separation while the IMS provides the drift time separation. At least three ion species are evident: background ions (RIP) (td = 2.15 ms, Vc = 9.2 V), monomer (td = 2.45 ms, Vc = 3.2 V), and dimer analyte ions (td = 3.2 ms, Vc = 2.5 V). Each isomer and dimer has both discrete time of flight (IMS) identifiers and discrete compensation voltage (DMS) identifiers. Therefore, if IMS detects a known monomer at td = 2.45 ms, DMS could quickly verify the presence of the monomer by adjusting to a Vc = 3.2 V and looking for a response, reducing the chances of a false positive.

Reviewing Figure 3, we can also see how chemical interferents in IMS could be identified and mitigated by detecting their presence in DMS and vice versa. IMS and DMS each have strengths and weaknesses but the two technologies are complementary when used together.

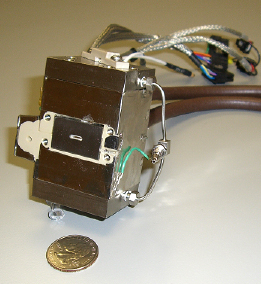

Figure 4. A photo of the Sionex DMS/IMS2 system |

Detector Applications

So what applications exist for such a detector? The hybrid detector's distinguishing attribute is its ability to provide two-dimensional data as well as discrete DMS and IMS data, resulting in both greater sensitivity and fewer false positives at very fast analysis times. Two applications that place a high premium on speed of analysis and minimal false positives are threat detection and medical diagnosis through breath analysis. Both of these also benefit from the small form factor that a DMS-IMS combination offers.

One important application is battlefield monitoring for CWAs, TICs, and TIMs. In a battlefield situation, the detector commonly would be subjected to interference from other chemicals in the environment, such as diesel and aqueous fire fighting foam (AFFF), which can dramatically complicate the task of detecting the target CWAs, TICs, and TIMs. The DMS/IMS detector would provide two data points to determine whether diesel or AFFF was masking a target CWA.

As in battlefield applications, first responders often need to distinguish the presence of toxic chemicals from among the confusing array of chemical mixtures that may result from a fire or an explosion, for example. The dual detector runs in discrete DMS and IMS modes as well as in a combined mode, allowing the collection of multiple forms of data to identify the chemical and determine its threat level.

Hybrid DMS-IMS technology is being used today to monitor high-asset buildings and plants, such as governmental buildings, financial institutions and banks, and power plants. Financial institutions and banks require monitoring systems that definitively identify threats to the health of their workers. A dual detector provides more information to confirm whether a chemical threat detected is an actual threat or a false positive. The data provide more information to enable an informed decision. Should an attack occur through a building's HVAC system, speed of analysis and confirmation is of utmost importance.

Breath analysis is an interesting emerging application used for diagnosis or as a therapeutic in identifying and curing diseases. It can also be used in threat detection monitoring to assess whether individuals have been using explosives or to determine where they have traveled. As in battlefield and first-responder applications, chemical interference is a major challenge in breath analysis: human breath contains thousands of volatile organic compounds at extremely low levels that cause enormous interference problems. Again, the dual detectors allow for greater sensitivity and selectivity of the target compounds.

In conclusion, a dual DMS and IMS detector enables identification and confirmation of compounds in the presence of interfering chemicals or complex matrices (i.e., samples with numerous chemical components) in seconds. It provides greater selectivity because it selects compounds based on compensation voltage and time of flight. Further, it gives fewer false positives and confirms the presence of a target chemical based on two data points rather than one.