Network engineers often avoid wireless solutions because they fear transmission interference. This can stem from high temperatures, echoes, vibrations, dust and other airborne particles, electromagnetic forces, and electrical noise. These negative events will make communication on the network unreliable and ultimately contribute to unwanted downtime.

Despite technological advancements in the space, wireless technologies often bring considerable reservations to those working in mission critical applications, since monitoring the network over long distances via wireless local area network (WLAN) connections can be tricky. Industrial environments bring a range of harsh settings and unique challenges that can make it difficult to use sensors, transmitters, and other communication devices in the field.

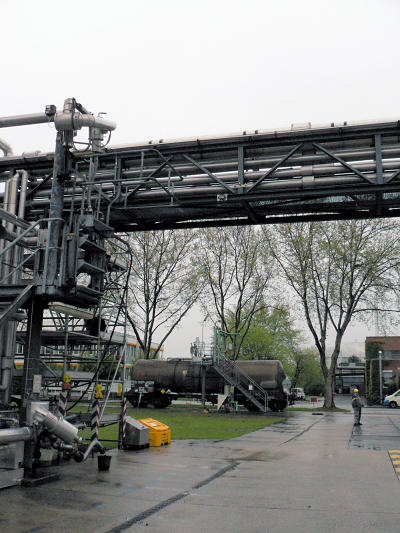

Industrial environments are often harsh, presenting unique challenges.

However, when implemented successfully, wireless technology can improve productivity and energy efficiency and bring a range of benefits to industrial applications. These benefits include:

-

Cost savings: WLANs reduce the need for duplicate personnel, additional local support and set up time, saving companies 10% to 30% on overall costs, depending on the particular application. Replacing connections prone to interference and moving the application toward maintenance-free radio communication also helps reduce costs.

-

Reliability: WLAN connections achieve reliable cable connections in 90% of applications and parallel redundancy protocol (PRP) can be implemented to increase signal transmission reliability even further.

- Competitive advantage: WLANs offer mobile network connections to applications, independent of their location within the production site. This connectivity contributes to shorter startup times, lower breakdown rates, and real-time status updates, which can help companies get a leg up on competition.

To fully leverage the robustness and availability of wireless technologies, engineers must pair them with an appropriate antenna solution. Although requirements differ depending on the particular application, there are several key technical factors to consider when evaluating antenna technology.

Directional vs. Omnidirectional Antennas

Directional antennas point radio frequency (RF) in a specific direction in order to concentrate it within a targeted area. These antennas are typically used for connecting buildings over point-to-point links in outdoor areas and have different opening angles — wide angles for short distances and acute angles for longer distances — in which they bundle the send/receive signals in a unidirectional way, generating a much greater coverage range.

Omnidirectional antennas provide equal coverage in all directions, with a sphere-like coverage pattern. These antennas are typically used for office rooms and interior or exterior open areas, due to their ability to cover a circular area. The particular range is dependent on the sensitivity of the antenna.

Multiple-in multiple-out (MIMO) antennas consist of a single structure containing up to three single antenna elements inside, each antenna actively using reflections and delays in signal propagation to combine more than one stream. This structure ultimately enables higher data rates and a better quality of connectivity in noisy environments.

Frequency Ranges

When specifying an antenna, the first step is to identify how large the coverage area needs to be. Antennas are typically grouped according to the following frequency ranges:

-

Frequency range: 2.4 GHz

- Short range: Up to 200 meters (218 yards) with omnidirectional antennas

- Medium range: Up to one kilometer (0.62 miles) with sector antennas

- Long range: Up to five kilometers (3.11 miles) with directional antennas

-

Frequency range: 5 GHz

- Short range: Up to 300 meters (328 yards) with omnidirectional antennas

- Medium range: Up to three kilometers (1.86 miles) with sector antennas

- Long range: Up to 15 kilometers (9.32 miles) with directional antennas

Does the signal need to cover a wide area such as a factory floor? Do moving clients — phones, laptops, tablets — require uninterrupted coverage of the entire area? Are small breaks in communication acceptable? Is this a simple, low data rate application, or a high bandwidth high-definition video? Understanding the answers to these questions will help decipher which frequency range best suits your needs.

Industrial applications

Ultimately, the type of antenna solution an engineer uses depends upon the particular application at hand. Three common situations requiring wireless technology are large and small industrial production sites and factory automation.

-

Sand loading unit supervision: Large production areas, such as areas for sand loading unit supervision, need maintenance-free solutions that can provide connections to transmit control and measurement data. Since these applications need to reach across areas ranging from 100 meters to one kilometer, directional antennas are an ideal solution as they ensure equal visibility between loading units and the central station along the entire route. Two directional antennas may be required in order to reach the desired coverage area, and they should be mounted on a fixed, central site. These antennas will support a signal-to-noise-ratio (SNR) of 20dB over the whole moving area.

-

SCADA system extension for control over final charging stations: In this application, the charging of process tanks needs to be controlled and monitored, but in order to evaluate the current status of each station, a physical inspection tour is required. In such situations, an omnidirectional antenna ensures wireless connectivity over the complete production area. This choice will greatly extend the coverage area so inspectors don't need to walk to the control unit near the tanks, which is a very hazardous area. By using an antenna that harnesses the power of MIMO technology, engineers can receive small signals from handheld devices and also distribute the signal throughout the desired area with more reliability. This option provides hemispheric coverage and aids in production control by sharing real-time updates and high throughput.

- Seamless connections across the factory floor: In factory automation environments, engineers need complete and redundant coverage of the entire factory, including the back-up system in the event that one part of the network fails. To ensure secure control of the automated guided vehicles, the network design of the factory floor needs to have an overlapping cellular structure. Omnidirectional antennas are the best option for installing these networks above the bearing surface and at high altitudes, usually under roof girders. This also makes it possible to restrict the extent of the radio cell via transmission power in order to achieve an optimal allocation of each radio area.

Antenna system on a typical factory floor.

Conclusion

Industrial environments are unique, and therefore require customizable solutions. Understanding the application's particular needs and challenges and knowing what to look for in an antenna solution, will help keep the network void of environmental interference and ultimately make communication for mission critical applications more reliable.

About the Author

Hans-Joachim Richter joined Belden in 2007, working with Hirschmann and Belden Electronics in the EMEA Competence Centre. Richter's main focus areas are in wireless, technical support, trouble shooting, project implementation, and training. Before joining Belden, Hans-Joachim held positions at a variety of companies, including Anixter, Bluesocket, Cisco, Lancom and ZyXel. If you have any questions, please contact Hans-Joachim Richter via email at: [email protected].

Related Stories

Modem Solutions Designed to Support Reliable, Global Connectivity to the Internet of Things

Fairview Microwave Introduces New RF Power Combiners Operating Up to 6 GHz