As more and more electronic components are finding their way into outdoor equipment and remote locations, the need for environmental monitoring around equipment is becoming more valuable. In these remote installations, electronics typically reside in sealed, weather-resistant enclosures or a climate-controlled room or closet. However, it is not always easy or cost-effective to perform physical checks of the environment in a weather-tight enclosure or remote room. Adding remote relative humidity (RH) and temperature sensing capabilities to these locations provides a low-cost means to monitor the environmental conditions around these electronics and prevent damage to equipment resulting from water or temperature ingress.

Consumer home monitoring products can also benefit from environmental sensing. By providing information about in-home humidity and temperature conditions, child care, and security monitoring products give parents and homeowners added peace of mind about the environmental conditions present inside their homes.

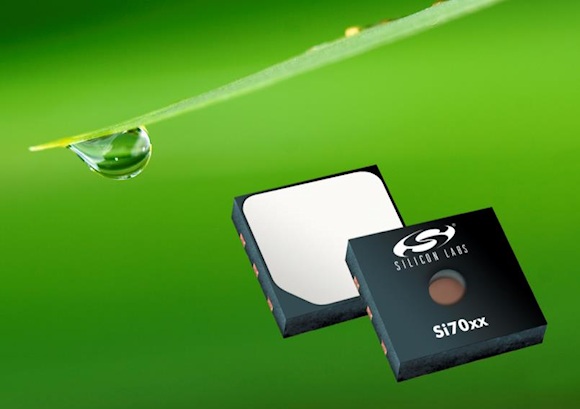

With the availability of integrated RH and temperature sensors such as the Si701x/2x sensor family (see fig. 1), high-precision humidity and temperature sensing capabilities can be added to electronic designs in a simple and cost-effective manner without the need for special calibration equipment, increased design complexity or a large bill of materials.

Fig. 1: Integrated Si701x/2x Relative Humidity and Temperature Sensors

Outdoor and Remote Electronics

Electronics that must operate outdoors require special design considerations to ensure proper operation across a wide range of weather conditions. In addition to supporting wider temperature ranges, it is necessary to prevent water and dirt from contaminating components. In addition, continuous operation at high humidity levels can cause corrosion of device terminals, leading to eventual device failure.

Protection from such elements is achievable by placing components behind protective covers or inside sealed enclosures. Examples of outdoor electronics applications include security cameras, ATM machines, vending machines, lighting and irrigation controllers, seismic data loggers, weather stations, radio equipment for emergency services personnel and military equipment.

Electronics may also require placement in remote installations many miles from the nearest service center or in a room rarely accessed. These installations often include a climate-control system for maintaining a protected operating environment. Examples are remote servers, data centers, telecommunications equipment, and cellular base stations. Due to their remote location, it may not be practical to directly monitor the environmental conditions in these installations on a regular, firsthand basis.

Available for many years now, low-cost thermistor and temperature sensor devices make remote temperature sensing an easy feature to add to most designs. While temperature sensing helps to monitor outdoor and remote electronics, temperature data alone does not provide a complete picture of environmental conditions for these products. Seals and gaskets for weather-resistant enclosures can fail, allowing water to enter the enclosure. Likewise, door and window frames or pipes in remote equipment rooms can leak water into the environment. In each of these cases, the presence of water can cause corrosion and/or flooding, resulting in expensive equipment failure, not detectable by temperature sensing alone until it is too late.

Adding remote RH sensing capabilities along with temperature sensing provides early warning of potentially damaging moisture buildup. In many cases, this sensing information allows enough time to repair broken seals or pipes before extensive damage occurs. Abnormal RH levels in remote equipment rooms can also be a sign of malfunctioning climate-control equipment. Early detection of this condition with RH sensors allows making the necessary repairs before equipment failure becomes a reality.

Consumer In-Home Environmental Monitoring

Consumers have a vested interest in being aware of the environmental conditions inside their homes. Baby monitors are popular products with parents who need to periodically check on their children while sleeping or playing in another room of the house. Adding remote RH and temperature sensors to baby monitors (see fig. 2 application example) gives parents additional peace of mind that their children are safe and in a comfortable environment. The RH measurement is also viable for determining if a humidifier is necessary to further safeguard a child's health.

Fig. 2: Baby Monitor Application with Integrated Humidity and Temperature Sensor

When homeowners are away from their residences, motion detectors and security cameras can detect break-ins, theft, and damage. Adding RH and temperature sensing to home security monitoring products not only provides an additional data point to suggest a possible broken window or door, but can also warn of an HVAC unit failure. This is a valuable early-warning capability in cold climates where freezing temperatures can cause broken pipes as well as in humid climates where high humidity can incur mold growth. Teaming with Internet-enabled monitoring applications, the value of in-home RH and temperature sensing increases by providing access to measurements from any Internet-connected device or phone at any time.

Design Challenges for Adding Relative Humidity Sensors

Traditional RH sensors consist of a discrete resistive or capacitive sensing element along with an external drive circuit to interface the sensing solution to an MCU. Until recently, adding RH sensing to a PCB design was a difficult process for the following reasons:

- RH sensing elements are often bulky and are not compatible with surface-mount technology (SMT) pick-and-place PCB assembly processes.

- If discrete RH sensors are to operate over a wide temperature range, additional components may be necessary to perform temperature compensation of the sensor response.

- Achieving reasonable accuracy requires end-of-line calibration with special equipment.

- During operation, discrete RH sensors can be susceptible to vibration and mechanical shocks.

- Due to the large number of analog components in the circuit design, traditional RH sensors may suffer from long-term drift of accuracy, further reducing sensor accuracy.

Given the multitude of factors to consider when adding RH sensing to a PCB design, it is understandable that designers may be reluctant to do so unless absolutely necessary to ensure the system's long-term reliability.

Integrated Relative Humidity and Temperature Sensors Simplify Designs

Thanks to new integrated RH and temperature sensor solutions such as Silicon Labs' Si701x/2x family, it is now a relatively simple and straightforward process to add robust and reliable RH and temperature sensing to PCB designs. State-of-the-art integrated sensors combine all the functions of a discrete RH sensor element, a discrete temperature sensor element, and related interface circuitry and temperature compensation into a single integrated circuit (see fig. 3).

Fig. 3: Example of Integrated RH/Temperature Sensor

The industry-standard I2C interface eliminates the need for a dedicated analog-to-digital converter (ADC) input when interfacing to MCUs. Packaged in industry-standard DFN packages, these integrated RH/temperature sensors are fully compatible with SMT pick-and-place assembly processes and are not susceptible to vibration. For battery-operated products, integrated RH and temperature sensors offer lower power consumption than their discrete counterparts. Best of all, these devices are fully factory calibrated, which eliminates the need for costly end-of-line calibration.

While in the past designers would have included temperature sensors in outdoor electronics applications and remote equipment, it is now practical to add RH sensing without any penalty in terms of PCB area or manufacturing complexity. For outdoor electronics, this provides a constant viewpoint of the conditions inside the sealed enclosure without the need to physically inspect the unit. For remote installations, integrated RH and temperature sensors enable much more frequent monitoring of the remote environment than would be practical with physical inspection. In either case, the small incremental cost of adding RH sensing in addition to temperature sensing can easily be justified through reduced maintenance costs and lower risk of equipment failure.

For consumer products, integrated RH and temperature sensors make it easy for designers to add RH and temperature sensing to consumer home monitoring products. With an extremely small PCB footprint, negligible bill of materials cost and an I2C interface, integrated RH and temperature sensors add value to in-home monitoring products with only a small increase in total system cost. Thanks to the low power consumption of these sensors, remote sensors can operate for years with just an inexpensive coin cell battery.

Summary

Whether designers are building electronics for outdoor applications, remote locations, or consumer in-home monitoring, integrating RH and temperature sensing to these products provides a more complete picture of the environmental conditions than temperature sensing alone. For outdoor electronics and remote installations, RH and temperature sensing can help prevent costly equipment failure.

For consumer in-home monitoring devices, RH and temperature sensing offers added value to parents and homeowners who will be using these devices. Thanks to current RH and temperature sensors like the Si701x/2x sensor family, designers can add RH and temperature sensing to embedded designs for a small incremental cost and without the need for complex and expensive calibration during PCB assembly.

ABOUT THE AUTHOR

Bill Simcoe serves as a product manager for Silicon Labs' environmental sensor products, focusing on the Si70xx relative humidity and temperature sensor family. He joined Silicon Labs in 2004 as an applications engineer and holds an MBA from The University of Texas at Austin and a bachelor's degree in Electrical Engineering from Georgia Institute of Technology.