Low Pressure

Accurate measurement of low pressure with respect to atmospheric reference (typically called vented or gauge reference) requires that pressure sensors breathe under dry, humid and wet conditions. In humid and wet environments, challenges are posed on how to operate the pressure sensor without allowing water into the back end of the sensors, causing the device to malfunction. In submersible water applications, the atmospheric-to-depth temperature differential can be significant for a pumping effect to occur where moist air can be drawn into the sensor via the vent line, causing condensation to attack sensitive electronic components to fail.

Low pressure can be termed as 500PSI (35Bar) or below where accurate measurements are to be made without the influence of altitude or barometric changes. As the full span of the pressure that is being measured increases, the effect of barometric pressure becomes a smaller percentage. Measuring pressure with a 5 PSI pressure transducer and 500 PSI pressure transducer will both have the same effect on their respective diaphragms, but the barometric pressure will change the output signal more on the 5 PSI than the 500 PSI transducer.

Sometimes, in outdoor applications where the pressure sensor is mounted to a water pump or another location that is exposed to the environment, a sealed gage or absolute referenced sensor may be used if the overall accuracy is not of significant importance. For example, a sealed gauge pressure sensor used on a water pump running at 150PSI can experience a 4 to 5 PSI difference based on atmospheric and ambient temperature changes. The 2.5-3.5% error may not be an important to the overall system; however, it does protect the sensor against the wet environment. Since the sensor is sealed, it is protected against water ingress through venting.

Next page

Transducers

Pressure transducers can be sealed in various methods, including those using epoxy and potting compounds. These materials are non-conductive should they contact any sensor conductors or circuitry. Housings that are welded to the electrical connection and sensor can be helium leak tested, pressurized, or examined by X-ray to ensure a complete seal from the external environment.

Cables and connectors are both common installation methods for pressure transducers. Water-tight cord grips can be installed as well as connectors with proven IP ratings. For example, some automotive applications require pressure sensors to be tested to IPX6K by applying a flow of 75 liters per minute for three minutes. The test simulates car wash survivability to ensure the pressure sensor will not have an electrical short during prolonged exposure to high pressure water streaming at the sensor.

Venting For Land-Base Pressure Sensors

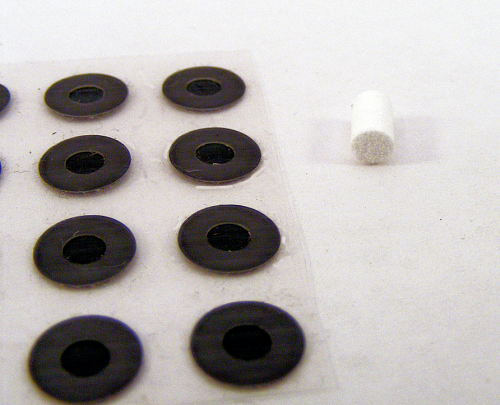

Gore-Tex vent plugs, patches and filters can help vented gauge sensors to breath in humid environments; however, they will not work if submerged in water. While the pore in the Gore-Tex filter is much smaller than the droplet of water, it is much large than the water vapor molecule. These plugs can be very useful as long as they are not abused physically. However, prolonged exposure to wet conditions will allow water vapor to condense inside the sensor if pumping is to occur under temperature gradients based on atmospheric and internal temperatures. See figures 1 & 2.

Fig. 1: This is a Gore-Tex patch that can be used on an enclosure or housing of the sensor.

Fig. 2: Here is shown a Gore-Tex plug that can be inserted into an integral sensor connector to provide venting.

Next page

Submersible Venting Of Sensors

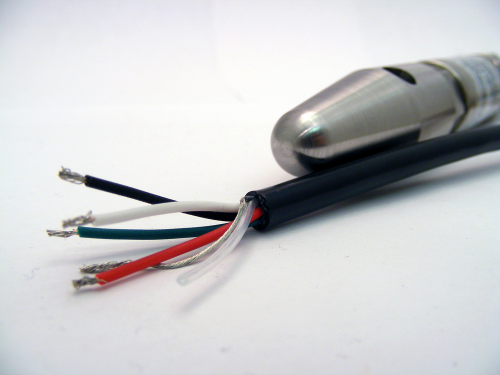

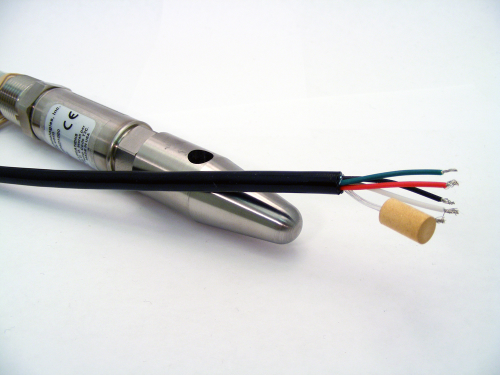

In submersion applications, the solution may not be as easy and requires a combination of cable venting and a special termination technique to avoid water ingress into submersible sensors.

Fig. 3. The vent tube performs as an integral part of the submersible cable. This tube is normally terminated inside an electrical enclosure or junction box that is allowed to breathe dry, non- corrosive gas or air.

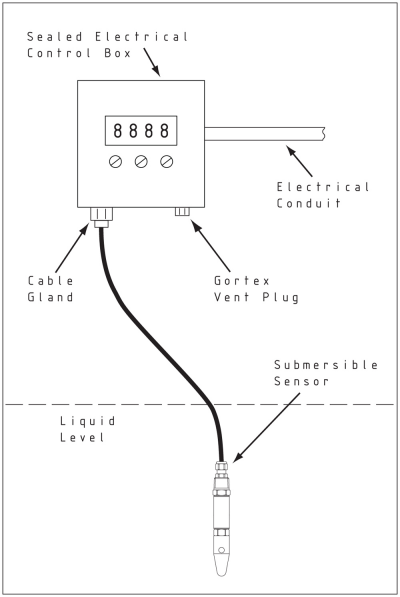

Fig. 4: This figure shows a typical outdoor installation where a Gore-Tex vent plug is used on the underside of the enclosure box to avoid direct water runoff over the vent plug. If the installation is indoors, the Gore-Tex vent plug can be ignored and all venting can be done through the electrical conduit which is normally dry.

In areas where the cable is terminated in a humid environment with some degree of protection from direct rain water or water spray, a Gore-Tex breather jacket can be installed on the end of the vent tube as shown in figure 5.

Next page

Wet-Wet Differential Pressure Sensor

In some demanding applications, like military, aerospace, offshore platforms and compressor pumping stations, wet-wet differential pressure (dP) sensors can be used.

A wet-wet differential sensor consists of two ports: P1 (high) and P2 (low). These devices can successfully measure very low gauge pressures from 0-5 inches (0-13mBar) of water column to tens of PSI on P1 while P2 is vented to the atmosphere. Since both sides of the wet-wet dP has some sort of metallic diaphragms and sealing against the media, there is no need to use Gore-Tex or vent tubes for venting. The metallic diaphragm on P2 protects the sensitive electronics against water and liquid ingress. The use of dPs is gaining more popularity in above ground tanks, steam generators, marine and offshore as the price of these devices decline.

About the Author

Karmjit S. Sidhu is the TE Director of Business Development – Sensors Oil & Gas TE Connectivity (American Sensor Technologies Pressure Sensors)

Related Stories

Easy-to-Use Calculation Tool Ensures Proper Size Selection for Pressure Regulating Valves

Sensing Technologies For Liquid Level And Depth Measurement Applications

Sensorex High-Temperature, High-Pressure Conductivity Sensor for Boilers