The U.S. now inspects 4% of the 6 million shipments arriving at more than 100 ports; before the September 11, 2001, attacks that figure was 2%. About 20% of the cargo passes through overseas ports such as Hong Kong, where U.S. inspectors are being stationed. Cargo worth $1.2 trillion, or half of U.S. imports, arrives by sea. The rest comes in from Canada and Mexico. Given the sheer volume of arriving merchandise, there is a good chance that some shipments will include unwelcome items. But how can they be discovered—and identified—without a lengthy inspection of every container?

|

Current sensor capabilities are fairly limited; in many cases, the best "technology" for practical use continues to be trained "sniffer" dogs. Manufactured sensors are often designed for use in specific environments, and to be selective for only one or two chemicals. The spectrum of potential threats, however, argues for sensor systems capable of detecting a large variety of chemicals. In addition, sensor systems need a number of different subsystems, including sample collection and processing, presentation of the chemicals to the sensor, and sensor arrays with molecular recognition.

In this article we present an electronic nose called the zNose that uses a single solid-state sensor to create an unlimited number of specific virtual chemical sensors for chemically profiling odors in cargo containers. Virtual sensor arrays and recognizable olfactory images for explosives, hazardous substances, illicit drugs, and even the cargo itself can provide a cost-effective screening tool for shippers and inspectors alike.

In support of container security protocols, odor profiles can also be attached to an electronic manifest file and forwarded to authorities at the country of destination for comparison purposes.

Chemical Profiling with High-Speed GC

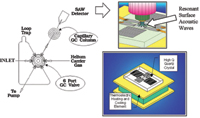

A portable chemical profiling system (Figure 1) incorporating an ultra-high-speed gas chromatography (GC) column, a solid-state sensor, a programmable gate array microprocessor, and an integrated vapor preconcentrator is able to speciate and quantify the vapor chemistry within a cargo container in 10 s.

Figure 1. Portable chemical profiling system incorporating an ultra-high–speed gas chromatograph |

Vapors within the container are sampled by inserting a sampling tube attached to the inlet of the instrument through a small opening in the container door, or through the ventilation ducts of the container (Figure 2).

Figure 2. Vapors are sampled by inserting a probe attached to the inlet of the instrument into a small resealable hole in the container |

The chromatograph system contains a minimum number of parts (Figure 3); temperature-programming a directly heated capillary column at rates up to 18°C/s produces 10 s chromatograms. A small capillary trap filled with Tenax (preconcentrates) samples the vapors and injects them into the capillary column. A key component of the system is a solid-state surface acoustic wave (SAW) detector that has zero dead volume and can detect quantities as small as 1 pg. The sensitivity of the 0.100 x 0.100 in. detector chip is dependent upon temperature, which is electronically controlled by a Peltier thermoelectric element.

Figure 3. Diagram of high-speed gas chromatograph and details of surface acoustic wave detector |

Olfactory Images and Virtual Chemical Sensors

The SAW sensor is nonionic and nonspecific. It directly measures the total mass of each chemical compound as it exits the gas chromatography column and condenses on the crystal surface, thus causing a change in the fundamental acoustic frequency of the crystal. Odor concentration is directly measured with this integrating type of detector. Column flux is obtained from a microprocessor that continuously calculates the derivative of the SAW frequency.

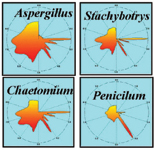

Plotting sensor frequency change (radial) vs. elution time (angle) produces a high-resolution 2D olfactory image called a VaporPrint (Figure 4). These images display the entire odor chemistry and enable the chemical profiling system to recognize complex odors and fragrances based upon their full chemical signatures.

Figure 4. VaporPrint olfactory images of four common microbial life forms |

Because different chemicals have different retention times, hundreds of specific virtual chemical sensors and sensor arrays can be created for trace detection. Virtual chemical sensors (Figure 5), combined with odor profiles, are effective for recognizing the signature of known hazardous materials. Retention-time indices of known chemicals relative to n-alkanes allows the use of an instrument-independent chemical library and electronic odor profiles for quick distribution that can be shared by many users.

Figure 5. Virtual chemical sensor arrays |

Profiling Cargo Container Odors

Explosives. The SAW sensor's nonspecificity allows it to detect and quantify the vapor concentration of virtually any explosive, independent of its chemical makeup (e.g., nitro or non-nitro). The probability of detecting explosives from fugitive emissions (vapor phase) depends strongly on the temperature of the cargo container, the vapor pressure of the chemicals, and the way they are packaged. Explosives such as Semtex and C4 contain high-molecular-weight chemical explosives (e.g., PETN and RDX), which are rarely detectable by vapor phase measurements. However, by international accord all manufacturers of "plastic" explosives must now include a volatile taggant compound such as DMNB or MNT, which enables dogs and vapor detection systems like the zNose to detect these explosives (Figure 6).

Figure 6. Chemical odor profile of C4 explosive |

Not all explosives have a nitrogen base, preventing detection by conventional explosive trace detectors. One example is triacetone triperoxide (TATP), which has the explosive power of RDX and yet contains no nitrogen. This compound was used by the shoe-bomber Richard Reid and is also favored by Israeli "human bombs." TATP is very volatile—as are NG, DNT, and TNT—and fugitive emissions from these explosives can now easily be detected in cargo containers.

Contraband Drugs. Some contraband drugs such as methamphetamine and marijuana produce odiferous compounds such as terpenes that can easily be detected in the vapor phase by canines and the SAW-based chemical profiling system. Other drugs, including cocaine and heroin are much more difficult to trace because their vapor pressure is extremely low. An array of virtual sensors can be created using odors from samples of the target drugs or by selecting the specific, more volatile compounds from the system's chemical library. For example, a natural by-product of cocaine is methyl benzoate, commonly called doggy-cocaine (Figure 7) because it is used to train canines to detect it. Whereas long sample preconcentration time and elevated temperatures were previously required, the presence of cocaine in a cargo container can now be detected using these more volatile compounds.

Figure 7. Volatile compounds in cargo container at room temperature |

Hazardous Chemicals. Many flammable organics, if properly sealed, may not be detected in a cargo shipment. But even a small leak can create a dangerous and even explosive vapor within the container. Vapors from gasoline and JP-8 aviation fuel are complex, containing many volatile organics, and are not easily separated by a single chemical sensor. They do, however, produce distinctly different olfactory images (Figure 8). Gasoline has more volatile compounds than JP-8. Creating virtual chemical sensors specific to both would be an important application for odor profiling in and around airports where JP-8 is a common background odor.

Figure 8. The chemical profiles of gasoline and JP-8 produce easily recognizable olfactory images and can be separated using arrays of virtual chemical sensors |

Biological Substances. Virtually all living organisms produce detectable volatile organics. Human cargo smuggled inside cargo containers might be discernible from the odor of human waste, with its high percentage of E. coli bacteria. E. coli produces a very recognizable olfactory image dominated by the chemical indole. Various molds and fungi that can contaminate, and some types of cargo as well, produce distinctive olfactory images and unique chemicals called microbial volatile organic compounds that can also be detected.

Security with Sensors

Cargo and port security are key components of the nation's homeland protection strategy. Helping in this effort is the zNose, a nonspecific sensor that, coupled with chromatographic separation, can produce high-resolution 2D olfactory images that can identify explosives, illicit drugs, hazardous chemicals, and biological nuisances such as molds and fungi. A single sensor can be used to create an unlimited number of specific virtual chemical sensors and can thus quickly adapt to changing threat vapors. Virtual sensor arrays and the olfactory images they produce provide a cost-effective screening tool for shippers and inspectors alike.

VaporPrint and zNose are registered trademarks of Electronic Sensor Technology Inc.

Edward J. Staples, PhD, can be reached at Electronic Sensor Technology Inc., Newbury Park, CA; 805-480-1994, [email protected] , www.znose.com.