Implantable medical devices are becoming safer, more diverse in their functionality and their use becoming more widespread, particularly with the rise of the IoT. Be that as it may, regardless of mainstream use and greater acceptance, implants still pose several risks, the two biggest being the human body’s ability to accept and integrate the implant and the risk of infection. University of Sydney researchers may have made some headway in reducing these risks.

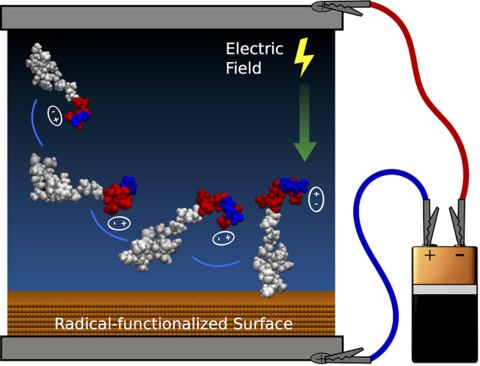

Finding what may be a new class of implantable devices, a team at the Applied Plasma Physics and Surface Engineering Laboratory has found a way to provide biological signals to surrounding tissue for better integration with the body while reducing the risk of infection. They have developed practical techniques to guide and attach peptides to surfaces. The team’s computer simulations and experiments demonstrate control of both peptide orientation and surface concentration, which can be achieved by applying an electric field like that delivered by a small household-sized battery.

Professor of Applied Physics and Surface Engineering Marcela Bilek points out that biomaterial coatings can mask the implanted devices and mimic surrounding tissue, “The holy grail is a surface that interacts seamlessly and naturally with host tissue through biomolecular signaling.” Robust attachment of biological molecules to the bio-device surface is required to achieve this, as enabled by unique surface modification processes developed by Professor Bilek. “Although proteins have successfully been used in many applications, they don’t always survive harsh sterilization treatments - and introduce the risk of pathogen transfer due to their production in micro-organisms.”

Professor Bilek - together with Dr Behnam Akhavan from the School of Aerospace, Mechanical and Mechatronic Engineering and the School of Physics and lead author PhD candidate, Lewis Martin from the School of Physics - are exploring the use of short protein segments called peptides that, when strategically designed, can recapitulate the function of the protein.

Lewis Martin says they could tune the orientation of extremely small biomolecules measuring less than 10 nm on the surface. “We used specialized equipment to perform the experiments, but the electric fields could be applied by anyone using a home electronics kit,” he said.

As per Dr. Akhavan, assuming industry support and funding for clinical trials, improved implants could be available to patients within five years. “The application of our approach ranges from bone-implants to cardiovascular stents and artificial blood vessels. For the bone implantable devices, for example, such modern bio-compatible surfaces will directly benefit patients suffering from bone fracture, osteoporosis, and bone cancer.”

Because of their small size, the peptides can be produced synthetically and they are resilient during sterilization. The main difficulty in using peptides is ensuring they are attached at appropriate densities and in orientations that effectively expose their active sites.

Image credit: University of Sydney.

Using applied electric fields and buffer chemistry, the researchers discovered several new levers that control peptide attachment. Charge separation on peptides creates permanent dipole moments that can be aligned with an electric field to provide optimal orientation of the molecules and the amount of peptide immobilized can also be tuned by the electrostatic interactions when the peptides have an overall charge.

Curiosity levels escalating? More info is available.