Next-Gen Medical Devices Benefit From TMR Tech

by Tanios BouRamia, Product Line Manager – Sensors & Switches at Coto Technology

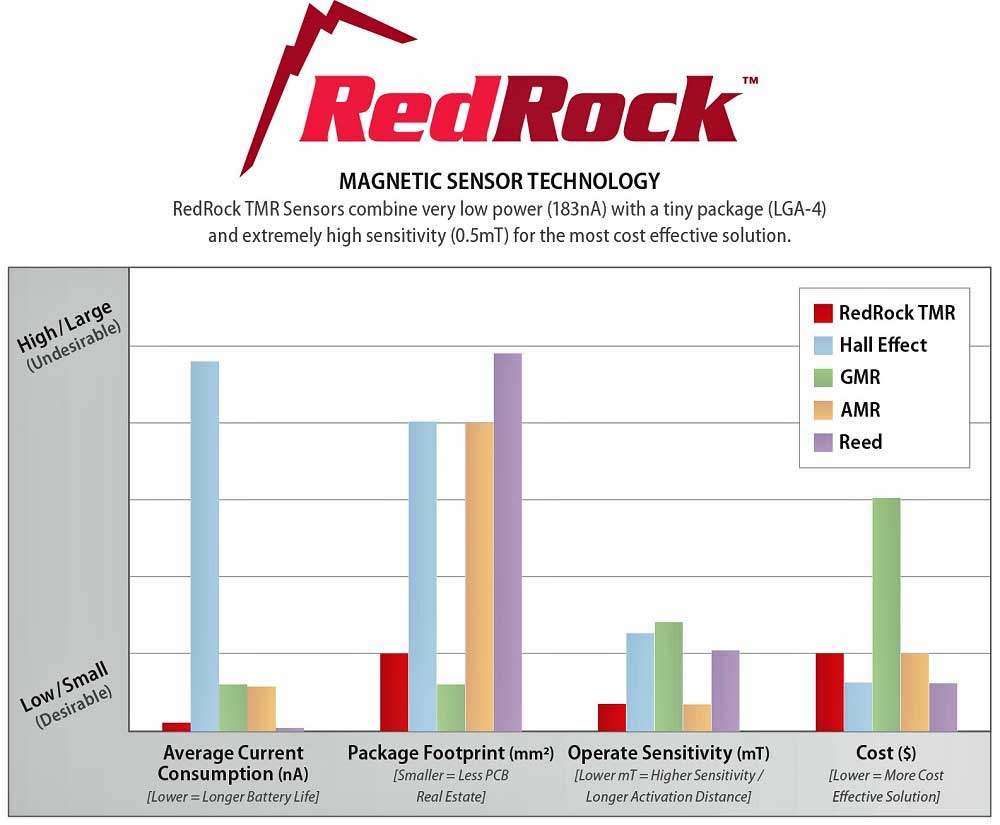

Three of the most critical factors for electronic sensors used in next-gen medical devices are low power, sensitivity and size. Tunneling magnetoresistance (TMR) is quickly becoming the preferred technology to address those requirements.

Many advanced medical devices rely on limited battery power, yet may be left in inventory for months before being used with a patient. Design engineers must minimize battery drain during that waiting period, lest the device not function when it’s finally turned on. One might think the easy solution would be to utilize a larger battery; however many of these devices are implanted, ingested, or carried on a patient, making size another critical factor that has to be minimized for functional or ergonomic reasons.

Yet another common requirement is the need to have a hermetically sealed device to maintain isolation between sensitive electronics and bodily tissues and fluids. That then requires a means of toggling the device without direct contact. While various magnetic sensing technologies offer solutions to that last hurdle, it becomes readily apparent, one technology in particular, tunnel magnetoresistance (TMR), is better suited than all others for solving ALL of the problematic design requirements of cutting edge medical electronic devices.

TMR sensors offer low power, high sensitivity, and incredibly tiny size. The technology itself is relatively simple in concept: two ferromagnetic layers, separated by a thin insulating layer that electrons can tunnel through, form a magnetic tunnel junction (MTJ) that functions much like a variable resistor. Without a magnetic field present, the two ferromagnetic layers are out of alignment, which leads to a low rate of electron tunneling and a relatively high resistance across the junction.

When a magnetic field is applied, the ferromagnetic layers align, increasing the rate at which electrons tunnel across the insulator so that the resistance drops significantly. The tunneling magnetoresistive effect is more than 1000x stronger than the Hall Effect, allowing far more sensitive devices, at smaller sizes and, because less amplification of the effect is needed to make a useful signal, significantly lower leakage current.

Other magnetic sensing technologies struggle with design trade-offs in one form or another. For years, bare glass reed switches were the staple of magnetic sensing applications demanding ultra-low power consumption, but their size reduction has reached the limit.

Hall Effect sensors’ reduced size meets the demands of compact modern electronics, but does so at the expense of high leakage currents and low sensitivity. Anisotropic and giant magnetoresistance technologies hinted at what might be possible but still struggled with relatively high leakage current.

Now with TMR sensors, design engineers can have the ideal magnetic sensor without giving up other desirable qualities. Low power, high sensitivity, and incredibly tiny size are all possible with TMR.

Coto Technology’s line of RedRock TMR sensors and switches offer a full complement of solutions for the next generation of medical devices. The RR110 series analog sensor is ideal in multipoint sensing applications such as liquid level sensing (e.g. insulin pumps with replaceable reservoirs or programmable dosage insulin pens). The RR120 series digital sensor offers seamless integration for “waking up” a microprocessor. The RR130 series digital switch can toggle larger control signals, providing a safety buffer of low voltage signaling between the human interface and high voltage power paths.

Coto will showcase its RedRock TMR technology at the upcoming Medical Sensors Design Conference in Newton, MA. Coto will lead a Learning Lab Interactive session on Monday, May 8 from 1:00pm - 2:00pm. Coto will discuss the technology of TMR, demonstrate how that technology is transformed into useful devices, and show where those devices are providing solutions for the next generation of magnetic sensing applications.

Attendees will experience Coto’s RedRock line of TMR analog and digital sensors and switches. Demonstration boards will be available for all to experiment, investigate, and learn, both guided by Coto engineers and independently during the session, which is expected to be highly interactive between both presenters and fellow attendees.