Viscosity, the resistance of a liquid to flow, is an important measurement requirement in industrial process control and OEM applications. Viscosity describes the retarding force that is proportional to the rate of deformation. This so-called shear rate has units of s–1 and describes the cross-stream gradient of the flow speed.

One of the most undesirable aspects of conventional viscosity measurement methods is that either the sensor mechanism or the liquid must be in motion. This requirement is true for flow-based systems such as capillary tubes, Coriolis force tubes, efflux cups, falling balls, moving pistons, and rotating spindles. While MEMS technology, and specifically lab-on-a-chip devices, may miniaturize this class of measurement device, fundamental physics and engineering factors complicate their use for embedded process control monitoring in which flow rates, particulates, and pressures play a crucial role.

Measuring Viscosity with a Surface Acoustic Wave Sensor |

There has been a long-standing effort to introduce solid-state technology for viscosity measurement. Several research projects have demonstrated prototypes of two sensors that take advantage of acoustic waves. One uses the popular thickness shear mode (TSM) quartz crystal device (see Figure 1) and tracked resonance damping and frequency shift in an advanced electronic circuit. The other uses a less well-known waveguide mode of a quartz plate and combines the TSM device's sensing mechanism with the wafer scale manufacturing capability of surface acoustic wave sensors.

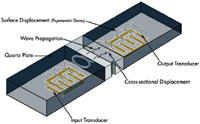

Figure 2. Differential measurements help reduce the circuit parasitic effects that plague low-cost thickness shear mode sensors. This viscometer incorporates an acoustic wave guide with electrical transducers on one surface; the other surface is in contact with the liquid of interest. |

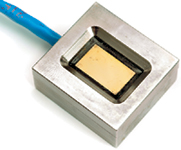

A new viscosity sensor developed by BiODE refines both sensor structures, overcoming challenges in design, reproducibility, and measurement range. This monolithic piezoelectric sensor offers the simplicity of the TSM while having distinct input and output ports for differential measurements. The benefits are enhanced reproducibility and minimized circuitry effects. This multireflective acoustic wave device blends the features of resonators and delay lines to offer a wide dynamic range (air to several thousand centipoise) in a single sensor, overcoming the major pitfalls of the earlier prototype designs (see Figure 2). ViSmart, a robust, reliable, portable, and cost-effective SAW solid-state viscometer (see Figure 3), is designed for integration into inline, real-time monitoring and process control systems. Aside from the atomic-scale vibration of the surface, ViSmart has no moving parts and, due to the high frequency of the vibration (several million vibrations per second), is independent of flow conditions of the liquid and immune to environmental vibration effects.

Figure 3. The solid-state ViSmart sensor is designed for inline, real-time monitoring and process control systems. |

Operating Principle

The advantages offered by ViSmart and other acoustic wave sensors lie in their principle of operation. Whereas one class of mechanical devices measures kinematic (flow) viscosity and the other measures intrinsic (friction) viscosity, acoustic wave sensors measure acoustic impedance:

where:

v = radian frequency (2πF)

r = density

h = intrinsic viscosity

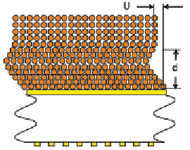

Placing the quartz crystal resonator into contact with the liquid of interest achieves the viscosity measurement. The liquid's viscosity determines the thickness of the fluid hydrodynamically coupled to the sensor surface, which is in uniform motion at frequency ω = 2πF, with amplitude U. The frequency is known by design, and amplitude is determined by the power level of the electrical signal applied to the sensor. The shear wave penetrates the fluid to a depth, d, determined by the frequency and the liquid's viscosity and density (see Figure 4):

Acoustic viscosity is calculated using power loss from the quartz resonator into the fluid. The unit of measure is acoustic viscosity:

|

The acoustic wave resonator supports a standing wave through its thickness. The wave pattern interacts with electrodes on the lower surface, which is hermetically sealed from the liquid, and interacts with the fluid on the upper surface. The bulk of the liquid is unaffected by the acoustic signal and a thin layer (on the order of microns or microinches) is moved by the vibrating surface.

|

Shear-rate-dependent effects are significant in acoustic wave sensors; they exhibit shear rates from a few thousand to several million inverse seconds. By comparison, rotary viscometers cover a range of <1 to ~10,000 s–1 . In contrast, lubricating oils experience shear rates of hundreds of thousands to tens of millions in today's engines.

Kerem Durdag, B.S. Applied Physics, M.S.M.E., can be reached at BiODE, Inc., Westbrook, ME; 207-856-6977, [email protected] , www.biode.com.