From Photographic Plate To CMOS Imager

Lens-free microscopy is a technique that can yield images with a resolution of 1 &mucro;m or below over a field-of-view that is orders-of-magnitude larger than in traditional microscopes. In addition, focusing, capturing the image, and interpreting it are completely digital. There is no need for manual intervention or mechanical calibration.

The principle behind lens-free imaging is holography. It was first formulated by the Hungarian-born engineer Dennis Gabor in the late 1940s, and eventually earned him a Nobel Prize. On a photographic plate, e proposed to capture the interference pattern between the light that illuminates an object and the light that diffracts of the object. This hologram contains both amplitude and phase information, and allows for reconstructing the image, including depth information.

Only recently, with the advent of powerful CCD- and CMOS-imagers, Gabor's photographic plate could be replaced with a fast high-resolution digital image sensor. And computers have become powerful enough to do the image reconstruction within a reasonable time. So labs around the world have started experimenting with lens-free holographic microscopy as a replacement and extension of traditional microscopes.

Specializing in image sensors and electronics integration, imec also set out to develop lens-free microscopy, but with a special aim. From the start, we were looking to make an industrial-strength solution. A solution that could be mass-produced and integrated, e.g., in tools that allow fast microscopic inspection of large surfaces.

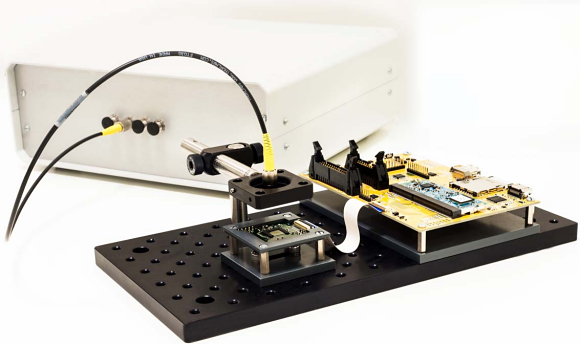

Fig. 1: Imec's CMOS-based lens-free microscope is designed to be mass-manufacturable and suitable for use in commercial labs and industrial environments. Characterized by a very large field of view, high resolution, fast reconstruction software, and excellent scalability, it offers the easy integration, e.g., in large-surface industrial inspection apps, bio-incubator environments, and micro-sized lab-on-chips.

There is much interest in such tools, particularly in the world of display manufacturing where forever larger displays are produced with ever smaller pixel sizes. Here, using automated inspection with traditional microscopes may slow down the manufacturing speed because the small field-of-view requires zillions of mechanical movements. Therefore, inspection by trained people is sometimes preferred over automated inspection.

Another notable domain where lens-free solutions bear great promises is biotechnology and life sciences. What attracts experts is the possibility to inspect living transparent cells, to monitor cultures and tissues, and to automate cell identification and inspection with smart image processing. In addition, lens-free technology is also a promising road for use as on-chip microscope integrated in future lab-on-chip technology.

Besting Phase-Contrast Microscopes

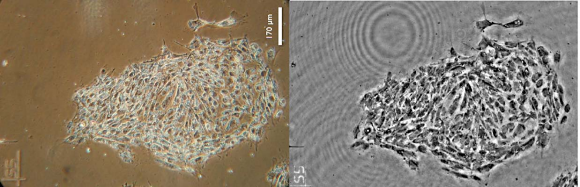

With the ability to look at living transparent cells, the lens-free microscope is pitted against phase-contrast microscopes. In these microscopes, however, you either have a fine resolution (looking at one cell), or a large field-of-view (looking at a colony)—never both at the same time.

Not so in a lens-free system, where the field-of-view and resolution are not mutually interdependent. For a wide field of view, you need a large-size imager, in our case a state-of-the-art monochrome 10-Mpixel imager. And the resolution largely depends on the imager's pixel size, 1.67 µm for our imager. With this setup and a fiber-optics coherent light source, we obtained a field-of-view of about 30 mm² for a 1.23-µm resolution, similar to the resolution of a phase-contrast microscope with 10x objective, but with a field-of-view that is 14 times larger.

Such a large field-of-view is especially useful in cell culturing applications where automated growth monitoring is needed. For these applications, you need a good enough resolution to observe single cells, but also cellular outgrowths and density variations in the whole colony. To do this with a phase-contrast microscope, you'd need mechanically moving stages, which may disrupt the colony, and image stitching.

Fig. 2: Stem cells seen through a phase contract microscope (left) and through imec's lens-free microscope (right).

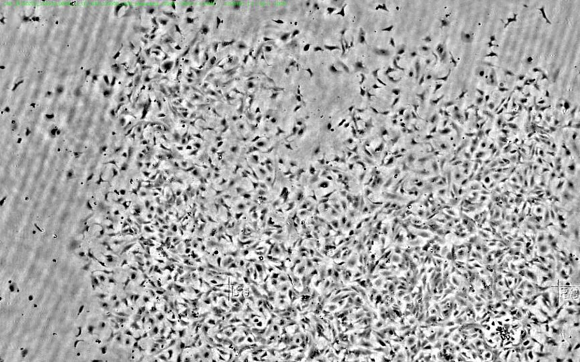

A second application we looked at is in-vitro drug testing. Currently a hot topic in drug discovery is to try and test potential new drugs on cells and tissues grown in the lab. An example is layers of contracting heart cells, which are infused with potential drugs to see if and how the contraction changes.

To monitor contracting heart cells and follow the speed of conduction from one cell to the next in a monolayer of cells, you need to look at the changing shape of a relevant number of cells. So you need a very large field-of-view, however, you don't necessarily need to see all the details of the cells.

But to see the changes in contraction, which may be subtle, you need a high imaging speed. The imec system manages an imaging speed of almost 300 frames per second, with higher speeds definitely possible.

Fig. 3: Horizontal view of a cardiac cell culture, approximately 2 mm.

A New Paradigm In Microscopy

With the exciting evolutions in biotechnology, we see many reputed partner companies involved in microelectronics or biotechnology, looking into this technology and challenging us to try and match our microscopes to their applications. As an R&D lab with design and fabrication capabilities, imec engineers are able to implement and integrate application requirements into working prototypes.

The result are compact solutions, mechanical robust, with little or no system recalibration or realignment, and requiring no maintenance. They can be scaled to a multi-microscope system with very large field-of-view. This is crucial in applications such as upscale stem cell production, lowering its cost and enabling more therapeutic applications. That way, lens-free microscopes are a new building block for innovative biotech applications, allowing these to grow to a level that would not be possible with traditional microscopy.

About the Authors

Andy Lambrechts received a MS and Ph.D. degree in electrical engineering from Leuven University. He is currently leading the integrated imaging team and is working on hyperspectral imaging, lens-free microscopy and other activities that combine imec's process technology with systems and software knowledge to enable new applications in the vision domain.

Jan Provoost is science editor at imec. Jan got his MA in languages in 1989 and his MS in computer science in 1993, both from the KU Leuven. He writes about imec's R&D for international magazines.

Related Stories

Endoscope with an oxygen sensor detects pancreatic cancer

Olympus 3D microscope used to recover data from damaged optical media

Agilent Adds ILM and STM Capabilities to Atomic Force Microscope