The growing demand for developed property is paralleled by the increasing need for irrigation. In reaction to these trends, local jurisdictions place tighter restrictions on water usage, and the cost of irrigation becomes significant. To reduce the cost of maintaining award-winning greens and fairways, Desert Mountain—a collection of six championship golf courses in the high Sonoran Desert north of Scottsdale, AZ—decided to install a wireless sensor network to take the guesswork out of turf management. With the aid of RF-enabled sensors, the club's director of agronomy, Shawn Emerson, has been able to reduce irrigation costs by 15%–20% and upgrade maintenance practices.

|

The Application

Emerson's primary job is to maintain healthy turf throughout the 1200 acres that make up the club's six golf courses. Until recently, he accomplished this by following old-school practices that relied on training, instinct, and the use of timers and clocks to regulate the courses' irrigation system. But as the cost of water increased to $150,000 per course each year, Emerson sought a more efficient way of controlling the irrigation process. In so doing, he turned to Advanced Sensor Technologies (AST), provider of a newly developed water management conservation technology based on wireless mesh networking and sensing devices customized for golf courses.

The premise of AST's business and technology is to control moisture in the soil profile. "Through the process of working with turf managers and irrigation companies, it became clear to us that having a smart irrigation control system is the wave of the future. We learned through the agronomy team in our company that the best way to make an irrigation decision is through what is going on in the soil. That is when we came up with the premise of a soil-monitoring system that measures moisture, salinity, and temperature levels," says Walt Norley, president and CEO of AST.

Although the use of sensors on golf courses is not new, AST had to develop technology to correct shortcomings of the past. "Historically, sensors have been around the golf business and the irrigated turf world for 20 years," says Norley. "Unfortunately, in the past most sensors were not precise or reliable enough. If you wanted something reliable and precise, you had to pay an extreme amount of money, and the market wasn't willing to do that. Our sensors are specifically calibrated for the turf that we are installing them in.

Checklist |

"The most important thing that we are trying to do is quantify our decision-making process about moisture in the ground," says Emerson. "Instead of using visual monitors, we decided we wanted to quantify everything that we were doing moisturewise."

Because Desert Mountain uses effluent water, Emerson and AST also used salinity sensors to monitor the total dissolved solids, the residual minerals dissolved in water that remain after evaporation of a solution. With sodium, or salts, in the water, irrigation can actually damage plants.

Finally, the application called for the use of temperature sensors to monitor the surface of the greens or fairways to determine the stress the turf is under at certain times of the day or year.

In addition to better irrigation control, the use of these three types of sensors enables Emerson to practice preventive maintenance. "There are certain diseases and environmental stresses that happen under certain parameters, and that's what the sensors can help you predict," says Emerson. "The objective is to predict things sooner than later because it's usually cheaper and more effective to practice preventive maintenance than curative maintenance. Most chemicals and amendments cost more to use in curative procedures than in preventive practices."

Adjusted Practices

The additional data provided by each type of sensor enabled Emerson and his staff to modify their irrigation practices in ways that would reduce the amount of water consumed—and thus lower the club's costs—while still maintaining healthy turf.

When Emerson and AST first installed the sensors, the moisture content of the soil profile was around 20%. They then began a process in which they gradually reduced the water used in irrigation. In so doing, they were able to determine the lowest threshold before the turf started turning brown, which was about 9%. This threshold varies by the season. By setting the watering threshold at 11% or 12%, they could cut the water usage without affecting the health of the turf.

The salinity sensor also comes into play as a tool for saving water. Because of the high salt content of the irrigation water, the golf courses have to "flush" their greens occasionally with extra water to push the salt down through the soil. Most golf course superintendents do this based on a calendar; it's a practice they learned in school and until recently they didn't have a way to quantify the salts.

Initially, the Desert Mountain courses performed this operation for about 90 min. twice a month. With the salinity sensors, Emerson and AST were able to determine that flushing 45 min. once a month removed the salts. Thus, they were able to reduce water consumption by a whopping 75%.

On top of all that, they are able to make correlations between water reduction and green speeds and green firmness. If they have a low-handicap guest coming in, they can adjust the moisture content of the green to achieve a desired speed and firmness.

The System

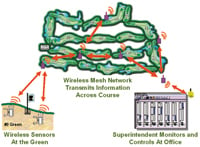

The sensors provide precise and reliable data collection, but the overall system lacked a means of delivering the data to the golf courses' central control center. This is where CrossBow Technology's wireless mesh network provided critical functionality.

Figure 1. Installation of in-ground sensor node |

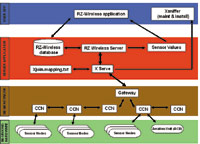

The system consists of in-ground sensor nodes (Figure 1), aboveground communication control nodes, the proprietary mesh networking stack, server middleware, and the back-end system, which allows the golf courses' staff to access the data in real time and control the monitoring system (Figure 2).

Figure 2. System architecture |

Each green and fairway equipped with the monitoring system has three in-ground nodes (Figure 3). These contain a 1 W radio, a battery, power management circuitry, and two sensor probes. Each probe contains a moisture, salinity, and temperature sensor, so the green or fairway has a total of 18 sensors monitoring the conditions.

Figure 3. In-ground node, which includes a radio, battery, power management circuitry, and sensor probes |

The radios are based on CrossBow's XMesh protocol (a proprietary mesh networking stack), and can transmit their data about 200 ft. The battery unit, with the aid of the power management capability, powers up and leaves sleep mode only to transmit data every 10 or 20 min. Battery life for the unit is expected to be five years. The radios are linked to the sensor probes by a hard-wired connection.

Figure 4. Communication control node |

The in-ground node transmits its data through the soil and then on to the aboveground communication control node (CCN). The CCN (Figure 4) consists of a 1 W radio, which has a range of 1.5 mi., and is powered by electricity drawn from the irrigation system. These nodes are on all the time. Most CCNs are mounted on an irrigation pedestal, which is about 3 ft. above the ground. Running the XMesh protocol, the CCNs form a mesh network, which links the units on individual greens and fairways back to the central base station located at the clubhouse (Figure 5).

Figure 5. Functional overview |

The mesh architecture is superior to peer-to-peer configurations in that the network cannot be brought down if a lightning strike or mechanical failure renders a CCN inoperable. Mesh networks reconfigure themselves if one of the network nodes fails; instead of relying on a single-point link between one of the radios and the clubhouse, they can actually relay messages over multiple, redundant paths, across a much longer distance.

The base station in the clubhouse is linked with a server running the XServe middleware, which manages the entire network. When network nodes are deployed and powered up, the middleware identifies them and decides whether or not to allow them to join the network. It assigns properties to each network node, manages the bidirectional flow of messages, and monitors the messages sent every 10 or 20 min. to indicate the health and operation of each node. This string of messages is like a heartbeat; it contains information on battery voltage and how many "neighbors" the radio can use to route messages to the base station. The middleware's Web interface allows you to monitor the health of the network via the Web.

The middleware also enables Desert Mountain staff to turn on sprinklers and adjust other irrigation controls. Through the software, the staff can change the sensors' sampling rate—how often the underground nodes wake up and transmit the sensor data. Through the server, the staff can reprogram not only the radios but also the sensors in the mesh network.

Finally, the middleware provides the network with a standards-based application programming interface (API). Thus, you have a complete XML API that allows you to easily integrate with other XML-based applications. This provides full access to all XML-based applications without requiring the user to learn the details of the message format used in the mesh network. That level of the protocol is abstracted for the user through the XML API.

The Payoff

AST's system has allowed Desert Mountain's golf courses to carefully tailor their irrigation practices, reducing water consumption and lowering maintenance expenses while ensuring healthy turf. The system also enables the staff to practice preventive care.

"The biggest thing that I've gained is my ability to verify decisions on green and fairway care through the use of sensor data," says Emerson. "Now I can quantify conditions."

Tom Kevan is a freelance writer specializing in technology. He can be reached at [email protected].