As industrial applications increasingly use process control systems utilizing sensor feedbacks to monitor various operating parameters, energy sources and consumption are becoming major factors of a system. In cases where power for a control system is generated from a local transformer or generator, operators do not need to worry about a few tens of milliamps of current.

However, if systems operate from a battery or solar panel-lithium source, power conservation must be maximized to extend power source life. Depending on application and environment, battery life expectations range from a minimum of a few months to ten years, in cases of remote oil and gas pipeline facility.

About 4 mA to 20 mA Two-Wire Loop Power

In cases where local power is abundantly available for sensors and processes, the 4 mA to 20 mA two-wire loop-powered system will still dominate over three-wire voltage outputs such as 0 to 5 Vdc or 0 to 10 Vdc. The 4 mA to 20 mA two-wire loop power has many advantages such as noise immunity over long cable runs, the ability to transmit over high impedances without loss of signal (assuming one has enough voltage drive to overcome the line impedances), and ease of current to voltage conversion.

Many manufacturers of programmable logic controllers (PLCs) and distributed control systems (DCS) have electronics cards that can drive and accept 4 mA to 20 mA inputs. For wireless and custom micro-controller (MCU) based systems employed and powered by solar panel-lithium battery combinations in remote oil and gas instrumentation, very few options exist for 4 mA to 20 mA since most of these device operate from 3.3 Vdc or 5 Vdc power supplies. Here, every milliamp of current counts and tight operating voltages are the norm.

Next page

Lower Power Requirements

Low power applications can be divided into two categories: continuous power or pulsed power that can dictate functional life based on a battery or solar panel-lithium combo. In flow and pressure measurements where readings are needed to monitor rapid changes, continuous power is applied. Here, devices need to operate at low power levels.

Fig. 1: A pressure transmitter designed to operate at less than 2 mA while operating at a 5V supply and ambient temperature changes from -40°C to 85°C (-40°F to 185°F).

Fig. 2 Here is a remote gas well with low power pressure sensors and wireless telemetry system with a solar panel-lithium battery power unit.

In pulsed power applications, typically the speed or response of the system is not needed. Here, the change in measurements take place over longer periods of time.

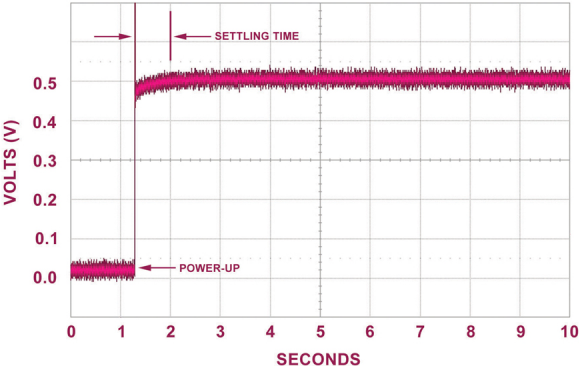

For example, levels do not change rapidly for a water holding tank, industrial gas cryogenic cylinder or fuel tank on a stand by generator. In these applications, operators can use two AA size batteries, operating at 3V, to run systems and still get plenty of life from the system. In these cases, the sensor is pulsed with power for a period of few hundred milliseconds to two seconds, depending upon the warm up time in the electronics, to take a stable reading before shutting the power to the sensor.

Fig. 3: The graph shows the settling time of the output of pressure sensor when power is applied. In this application, power is applied for two seconds to the sensors to extract data and transit it via wireless link.

About the Author

Karmjit Sidhu is vice president, Business Development, for American Sensor Technologies, now part of the Sensor Solutions team at TE Connectivity, where he spearheads sales and marketing and also focuses his efforts on the conceptual design of new products. Prior to co-founding AST, Karmjit was Chief Transducer Engineer for Measurement Specialties, responsible for the growth of their pressure sensor business. In addition to holding a BS in Electrical & Electronics Engineering and a MS in Industrial Measurement Systems from Brunel University, England, Karmjit is also a Doctoral candidate at New Jersey Institute of Technology (NJIT). Karmjit can be reached at [email protected] or 973-448-1901. For more information on American Sensor Technologies, visit www.astsensors.com.

Related Stories

TE Connectivity MS8607-02BA01 PHT Sensor Performs Accurate Environmental Monitoring

Semtech LoRa Wireless RF Technology Adopted by A2A for New Smart City Initiative