For many years, spectroscopy has been used to identify materials through their characteristic optical absorption or emission lines in applications ranging from astronomy to chemical analysis in laboratories. This article describes two families of spectral imaging that take this concept one step further and allow the user to visualize the variation of a material’s composition caused, for example, by localized contamination, or to discriminate between materials where this is not possible with the naked eye. We then describe some novel designs of spectral imaging sensor currently under development.

Spectroscopy And Hyperspectral Imaging Sensors

A wealth of information is available in the optical reflection or fluorescence spectra of many materials, and spectroscopic analysis is a well-established family of techniques used to analyze composition. Classical spectroscopy generally involves recording a single, averaged optical spectrum over part of the surface of an object under test and in its raw form is unable to identify or discriminate spatial variation.

Hyperspectral imaging (HSI) sensors are being used increasingly in a wide range of industries to record digital images which capture information on the optical spectrum detected at each pixel. Collecting hundreds of optical wavelengths, from ultra-violet to infra-red, applications include:

- satellite imaging of the earth’s surface (discrimination between land types, sea, vegetation, etc.); this was one of the earliest applications of the technology,

- environmental monitoring (detection of gas leaks, pollution, etc.) and

- medical imaging (diagnosis of diseases).

In all these applications the key enabler is the ability of HSI to capture high quality spectral data from and, hence, infer chemical composition at each pixel in an image.

There are multiple approaches to design of an HSI system and no one technology can claim outright superiority. Trade-offs must be made between spectral bandwidth and resolution, physical dimensions, spatial resolution, optical loss/throughput and (computational) image processing time; these are all performance factors which must be considered when selecting an imaging approach.

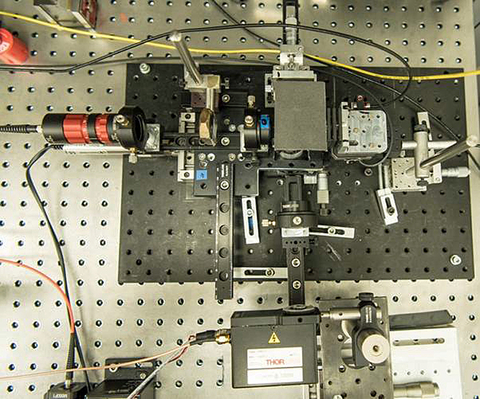

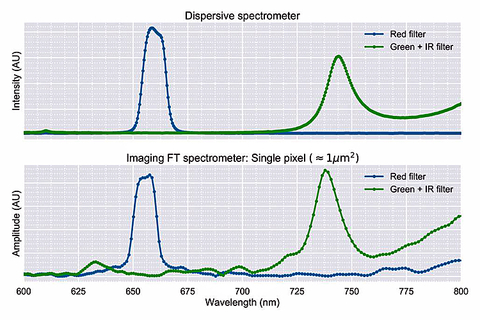

Typically, the HSI sensor is configured as a high-performance device for collection of high quality spectral data in a controlled laboratory environment. AS an example, Cambridge Consultants is developing a range of high performance 1D (so-called push-broom configuration) and 2D hyperspectral imaging sensors based on a new design of Fourier Transform (FT) Spectrometer. This approach offers several advantages over conventional devices:

- Robustness: the unique optical configuration makes the sensors particularly suitable for use in demanding environments.

- High resolution: The technology enables high resolution 2D (typically 5-μm spatial, 1-nm spectral) or medium resolution 1D (typically 20-μm spatial, <10-nm spectral) hyperspectral imaging at visible to near infrared wavelengths.

- High efficiency: High optical efficiency and signal to noise ratio (SNR) offers high speed and/or wide dynamic range measurements.

- Flexibility: The sensor can be designed for near- or far-field imaging, or for coupling via optical fibres to a remote sensing location.

- Reduced cost: The simplified design minimizes cost.

Applications that could benefit from this FT Spectrometer approach include those requiring high spectral and spatial resolution such as Raman and fluorescence imaging, multi-channel spectral photometry, and multi-spectral droplet fluorescence measurements.

Multispectral Imaging

The Hyperspectral Imaging approach provides flexible, high-performance acquisition of spectral information and is ideally suited to laboratory measurements. However, for industrial applications it is often over-specified and uneconomical. In a manufacturing environment for example, the requirement may be to detect just a few pre-determined materials and so measurement at just a small number of wavelengths may be sufficient. A Multispectral Imaging (MSI) approach can provide an economical means of recording images at a smaller number of pre-determined wavelengths. Typically, three to ten wavelengths are used, tailored to the materials/contaminants or conditions of concern. These can be provided by multiple LEDs or optical filters.

MSI offers a simpler, lower-cost, application-specific approach than a full HSI system. This approach has been proven in agricultural and personal care applications as follows:

- inspection of food (crop ripeness and size)

- precision agriculture (mapping of crops)

- personal care (foundation matching and sunscreen coverage)

Personal Care – ‘Skintuition’

Using off-the-shelf camera technology and integrated algorithms, the Skintuition platform technology images human skin at up to 12 different wavelengths simultaneously. This allows imaging in the UV and infra-red using a low-cost smartphone camera and a ring of LEDs.

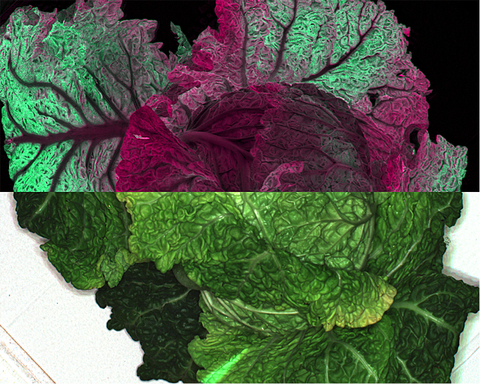

Agricultural Crop Mapping

The Skintuition platform was adapted to predict agricultural crop yields based on in-field imaging. LEDs were selected to target chlorophyll and the resulting images were analyzed to discriminate between the core plant “head” and surrounding leaves. This approach allowed for accurate size estimation in real time for each individual plant in a field. For the operator this enables generation of a size distribution curve and yield map, allowing for greater optimization of the supply chain and hence more informed price negotiations with customers.

HIS/MSI For Lab And Practical Industrial Applications

To select the most appropriate approach for an application it is useful to consider the pros and cons of each:

|

HSI |

MSI |

|

Pseudo-continuous spectrum (100s of wavelengths) |

Several discrete wavelengths (typically 3-10) |

|

Greater flexibility and resolution |

(Fixed) wavelengths selected according to specific application |

|

1-10 frames per second image capture |

Faster data acquisition (30 frames per second) |

|

Higher cost and complexity |

Lower cost, increased robustness |

|

More data processing required |

Reduced data processing requirements |

|

Better suited as a research/science tool |

Well-suited to repetitive, production/industrial applications |

Overall, HSI has traditionally been used in scientific and laboratory applications due to its higher cost and flexibility. With the advent of lower cost, simpler designs, such as those from Cambridge Consultants, there is now great potential for its adoption outside the laboratory. However, for many industrial applications, materials of interest are well-defined and as such MSI is well-suited, as has been demonstrated by Cambridge Consultants in several agricultural and personal care examples.

About the author

Andrew Strong is a Physicist, Chartered Engineer (CEng) and Fellow of the Institution of Engineering and Technology (FIET) in the Industrial & Energy group at Cambridge Consultants, based in Cambridge, UK. He brings over 30 years’ experience in a variety of optical sensing and industrial applications, from academic research to commercialization and deployment of novel sensor types. He can be reached via at [email protected] and/or telephone at +44 1223 420024.