The automobile is one of the harshest electromagnetic environments there is. A multitude of sensitive electronic circuits are fitted near many sources of noise. High-voltage ignition systems, electric wiper motors, and even simple turn signals – to name but a few – result in the emission of interferences that can wreak havoc on the systems in the vehicle. If we add to that the noise generated by cellphones, communication radios, high-voltage power lines and even from nearby vehicles, the noise levels get even worse. And if that is not enough, cars are always on the move at varying speeds, with different equipment switched on, and in different places, meaning that the noise environment the in-vehicle systems are exposed to is continuously changing and unpredictable.

There was a time when in-vehicle electromagnetic interference (EMI, also referred to as electromagnetic compatibility or EMC) was little more than an annoyance, leading to audible noises on the car radio but no more than that. However, the rapid progress of vehicle technology means that cars today are fitted with large numbers of ECUs (Electronic Control Units) driving high-bandwidth digital data streams, many of which are responsible for safety-critical functions. As the car of the future becomes a reality today with the introduction of autonomous technologies, the number of electronic systems continues to grow and the potential risks from EMC-related failures dramatically increase.

There have been numerous instances of vehicle failures in the recent past caused by electromagnetic interference, or to be more precise, by a lack of EMC robustness. From airbags firing when cellphones ring, to ABS braking issues caused by radio transmitters, and even complete vehicle shutdowns when passing by weather radar stations, a lack of immunity to external noise sources can have potentially catastrophic effects. The risks also arise from in-vehicle systems emitting noise to their surroundings, as the currents flowing in the wiring harness generate radiated magnetic fields and as such, introduce alien crosstalk to adjacent wires. This is compounded by the ever-increasing bandwidth in the car, as faster data rates lead to higher signal (clock) speeds that emit more noise than before and make the systems more susceptible to the effects of external noise.

Without doubt, automotive OEMs and Tier-1s have, over the years, greatly improved the EMC performance of in-vehicle systems and, with data rates still low, this has been achieved without the need to move to shielded cables. However, as data rates now move to 1G and beyond, the requirement to use shielded cables seems inevitable. When implemented correctly, shielding provides a barrier to RF (radio frequency) noise, both radiated and conducted. But shielded cables also bring with them many drawbacks:

- Shielded cables are heavier than unshielded, adding to overall vehicle weight and resulting in lower fuel efficiency and/or battery range

- Shielded cables are more expensive than unshielded, as are the connectors needed for these cables

- Shielded cables are less flexible than unshielded, and have a larger diameter, which can lead to routing issues within the vehicle and installation complexities

- Shielded cables may create ground loops, which themselves introduce noise into the cable and lead to signal degradation. To prevent this occurring, engineering teams are required to create a total system design which is tailored to a complete shielding concept, and this in turn results in increased costs and complexity.

So, faced with a need for more and more high-speed data links, OEMs are being driven to use large numbers of shielded cables which are expensive, difficult to work with and heavy. Far from the ideal approach for in-vehicle connectivity. But there is another solution for the EMC challenge.

A New Approach with HDBaseT Automotive

For years, HDBaseT has been the leading major connectivity solution provider in different markets including consumer electronics, professional audiovisual (ProAV), industrial automation and healthcare. Developed by Valens – who is also the chip vendor – HDBaseT technology converges multiple data types to run over a single, unshielded cable carrying multi-gigabit data. Realizing the importance of driving a standard solution, Valens were one of the founders of the HDBaseT Alliance, a not-for-profit organization comprising more than 200-member companies who develop and use the technology.

HDBaseT Automotive brings to in-vehicle connectivity many benefits including:

- Convergence of multiple data protocols to a single HDBaseT data stream

- Multi-gigabit bandwidth which can be either symmetrical or asymmetrical

- Networking capabilities to create complex architectures and topologies

- The use of a single, unshielded twisted-pair (UTP) cable – up to 15m/50ft long – as the transmission medium, even under the challenging automotive EMC-rich environment

The last point may come as a surprise but, unlike other high-speed in-vehicle connectivity solutions, HDBaseT Automotive is specifically designed to work over unshielded cables. That is not to say that it cannot work over shielded cables – it can – but it is the ability of HDBaseT Automotive to meet the exacting EMC requirements of the automotive industry on unshielded cables that is helping OEMs and Tier-1s to redefine their connectivity systems.

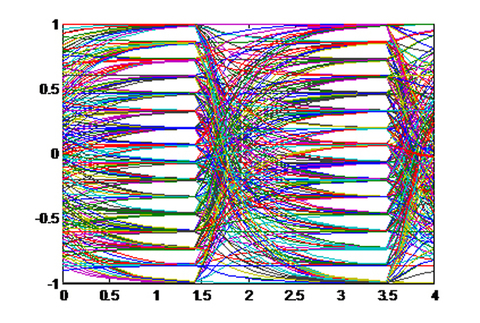

So how does HDBaseT Automotive transfer multi-gigabit data across unshielded cables without being affected by radiated and conducted EMC emissions or Bulk Current Injection (BCI)? Key to this is the architecture of the HDBaseT chipset which employs dedicated, highly-advanced analog front-end circuits that work in conjunction with hard-wired DSP (Digital Signal Processing) mechanisms. These structures allow for the HDBaseT data to be transmitted using PAM-16 coding, where each of the sixteen voltage levels on the cable encodes four bits of data (figure 1). By transferring so many data bits on each clock cycle, very high data bandwidth can be achieved using slower clock speeds than would be possible with a different coding scheme. And as was mentioned earlier, the slower the clock speed the lower the radiated emissions and the lower the susceptibility to external noise.

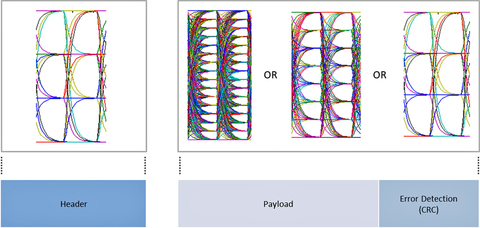

To protect the essential packet headers and critical data, HDBaseT employs subset modulation which encodes different data types with different numbers of PAM levels (such as PAM-8 and PAM-4). The lower the number of PAM levels, the greater the robustness of the data transfer and the lower the likelihood of critical data being received with errors (figure 2).

However, the use of PAM-16 signaling is only part of the answer. Unlike other technologies that avoid EMC interferences (for example, by relying on shielded cables), HDBaseT actually ‘learns’ the noise and, therefore, adapts to the noise environment. This is achieved using a fast-adaptive noise canceller that can greatly reduce the effects that external noises have on the HDBaseT link.

Should noise make it through the canceller, additional mechanisms are employed to ensure data corruption does not happen. HDBaseT is a packet-based technology, and each packet has a checksum (CRC) added to it for error checking in the receiver (figure 3).

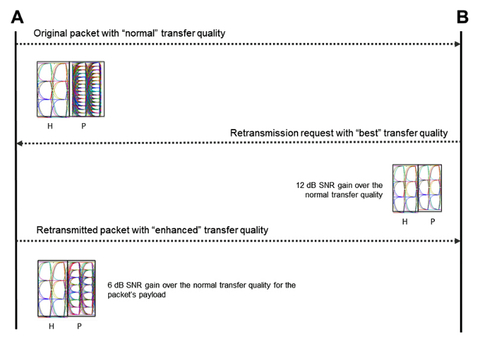

If the receiver detects a packet error, it sends a request to the transmitter asking for the bad packet to be retransmitted. However, since the retransmission uses a lower PAM level than the original packet, the probability of the retransmitted packet being received with errors falls to near zero. This Dynamic Modulated Local Retransmission (DMLR) is a highly efficient error correction technique and enables HDBaseT to provide excellent performance while operating under very noisy link conditions (figure. These different mechanisms that are employed to protect the data prove especially important during the time it takes for the noise canceller to adapt itself to changing noise levels.

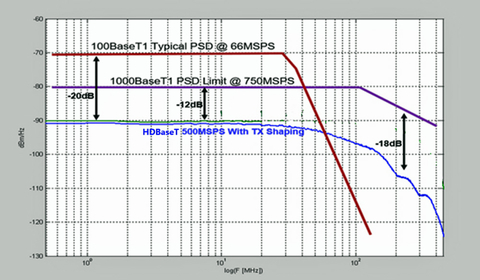

The final part of the HDBaseT EMC solution relates to the power spectral density (PSD) of the transmitted signal. PSD describes the power present in the signal (energy) as a function of the signal frequency. Since HDBaseT is highly robust in terms of immunity from external noises there is no need for it to transmit a higher power signal to overcome the effect of that noise – and this lower power signal directly correlates to lower EMC emissions from the HDBaseT link (figure 5).

When taking all the different elements of the HDBaseT solution into consideration, the adaptation to noise together with the retransmission mechanism provides ~40dB immunity gain to compensate for the lower transmitter PSD and the small voltage difference between PAM-16 levels. That means HDBaseT attenuates the common-mode noise from its input by a factor of 100, and that is why it can achieve outstanding performance and reliability on the simplest and most cost-effective unshielded cables.

Moving From Theory to Practice

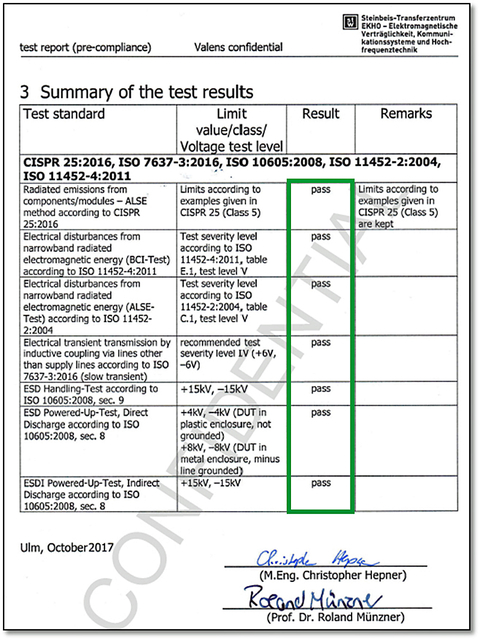

HDBaseT Automotive EMC performance is not just theory. Valens chipsets have been tested for EMC immunity and radiation at Steinbeis Transferzentren GmbH an der Hochschule Ulm (Ulm University of Applied Sciences) in Germany, a leading test house for automotive EMC. Many scenarios were tested at the ECU level according to ISO and CISPR Standards. The HDBaseT chipsets passed all tests, as can be seen from the summary of the test report below (figure 6).

Beyond the ECU-level, HDBaseT Automotive chips have already passed in-car testing for multi-gigabit data rates over UTP cables at one of the company’s automotive customers, and is the first multi-gigabit technology to pass in-car testing at a leading OEM. HDBaseT continues to be tested by many other OEMs and Tier-1s, and the results continue to impress the industry.

The use of unshielded cabling and connectors while maintaining best-in-class EMC performance at multi-gigabit link speeds is a crucial factor in reducing system costs and, therefore, total vehicle cost. Further, EMC robustness is a central element towards realizing the dream of the autonomous car. Addressing each of the different challenges of in-vehicle connectivity – high-bandwidth, cabling weight, different interfaces – is crucial. However, without the proper technology to handle the increased risks from electromagnetic interference expected with the growth of electronic systems in our cars, the reality of the autonomous car will not become a reality. HDBaseT Automotive is the one technology with in-built mechanisms to neutralize electromagnetic interference, and guarantee a smooth ride toward autonomy.

About the author

Daniel Shwartzberg, Director of Customer Experience at Valens Automotive.