When I first learned of MEMS technology, years ago, visions of great advancements in every field danced through my mind. For example, the idea of one day soon, a micro-electro-mechanical system (MEMS) of microscopic proportions could be injected into humans and animals for either routine diagnostics or non-invasive surgery. A device that could barely, if at all, be seen by the eye, injected into a person locates a point of concern, assembles itself into a surgical tool, performs the necessary operation, breaks down to its original state, and returns to the original injection site for easy removal.

Since that day of enlightenment, though somewhat dimmed by lofty expectations, MEMS devices have found their way into many applications. Of course, most of these have been commercial and consumer oriented with some usage in the biomedical arena. And despite a wide array of suitable applications, MEMS is really not quite mainstream yet. One reason is, MEMS devices are a bit more expensive than standard components. Also, they sometimes require unique design strategies that may add a few pennies to the cost of the end product. However, like any other technology, the price will go down eventually.

MEMS Rhymes & Reasons

Rather than philosophize, suppose, assume, or, even worse, guess about MEMS’ current state and where it will go, it’s always best to consult the experts. For example, Sensors Online hosted a webinar titled “Sensors/MEMS Marketing: Oxymoron or Opportunity”, presented by acknowledged MEMS marketing expert, Roger Grace. Expanding upon his eight-part series of the same title, Mr. Grace beamed light upon many of the reasons why MEMS OEMs do not reach their full potential and profitability. Along with those reasons, Roger offered many viable solutions.

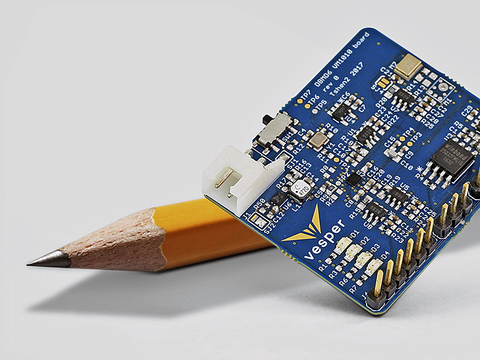

For this diatribe, we tap the mind of another MEMS expert. Mr. Bobby Littrel is the CTO and co-founder of Vesper, a company that employs piezoelectric materials to create advanced MEMS microphones. According to Vesper CEO Matt Crowely, “Bobby pioneered Vesper’s piezoelectric MEMS microphones, the first MEMS microphones that are rugged enough to keep working if you boil them in oil, immerse them in Boston Harbor, or expose them to other harsh environmental conditions. Bobby also led the design team for the VM1010, the first ZeroPower Listening MEMS microphone for battery-powered devices.”

Uniquely different than capacitive MEMS microphones, piezoelectric MEMS microphones directly convert mechanical sound energy into electrical energy. For example, Vesper’s VM1010 emerged as the industry’s first wake-on sound piezoelectric MEMS microphone that enables voice activation in a wide range of battery-powered devices. It is the first such device that uses sound energy to wake the host system up from a full power-down mode.

consumption of 6 µA in wake-on-sound mode and 90 µA in operation.

As a side note, the Vesper engineering team took top honors at 2017’s Sensors Expo West in San Jose, CA. The Engineering Excellence Award for best engineering team went to a six-designer crew at Vesper. The fruit of their labors, that which snagged the award for them? You guessed it, the VM1010.

What Vesper Has To Say About MEMS

To garner greater insight into the ways of MEMS, I recently asked Bobby Littrel a series of questions, which he graciously answered offering much food for thought on the subject.

Mat Dirjish (MD): From early on, MEMS was/is a technology that draws great interest in the engineering community. Probably more than any other technology, MEMS is intermittently touted as being the next big thing, however, in comparison to other technologies, there seems to be much less in the way of new products coming from the MEMS market. Do you find that to be true or is it just a matter that MEMS designers do not announce all their wares upon market release?

Bobby Littrel (BL): MEMS has always been an exciting and interesting technology for the engineering community, but it has remained a stubbornly difficult technology to develop into products. Because each MEMS device requires a custom wafer process, the development of a new MEMS requires several separate subprojects including MEMS process development, MEMS design, ASIC design, custom package design and custom test development.

As the foundry and OSAT infrastructure has matured this has gotten somewhat easier, but compared to software or digital semiconductor the product development is just far more difficult. In addition, because each of these subprojects must be successful to have a project, a holdup in one area will prevent the product from shipping. The “S” in MEMS stands for system, so you are really developing a microscale system through the entire technology stack from basic material science and chemistry to algorithms and system implementation. I suppose this is a long way of saying that the initial excitement in the MEMS early days to the sobering realization of how difficult MEMS are to develop.

MD: Currently, what are the most fruitful markets for MEMS devices, i.e., manufacturing, audio, video, medical, aerospace, etc.

BL: The good news is that once you have developed a successful MEMS process platform it should be extensible into multiple markets. I do believe that the next wave of technology will have information transducers, i.e., sensors, as a critical component. The diversity of applications extends into almost any electronic device you can imagine. Healthcare, automotive, smart cities, hearables, industrial and smart homes are all huge growth opportunities for MEMS.

MD: What are some of the MEMS devices that find application in those markets?

BL: The best inspiration I have for how MEMS will be used is the natural world and how living organisms use their sense capabilities to understand and react to the environment. For example, microphones can be thought of as generalized acoustic sensors. Historically they were used to record music and speech so that it could be stored and transmitted. Now we see microphones that are primarily used for interfacing with a virtual assistant such as Alexa or Siri. In the future we will see acoustics used more for acoustic event detection and predictive maintenance. All of these are things that humans already do with our ears. In some cases, we can even exceed natures capabilities. For example, most animals have two ears to get some directional information about sound sources. New systems like the Amazon Echo use seven microphones to take this ability to a new level.

MD: In terms of emerging markets, there is without doubt great opportunities for MEMS devices. Right now, the three areas showing the greatest potential and generating the most heated debates are artificial intelligence (AI), virtual reality (VR), and augmented reality (AR). Right on the heels of these technologies is autonomous vehicles and any and all health/fitness/medical devices. Obviously, each one of these offers great opportunities for innovative MEMS designers. Which ones do you find the most interesting and those you feel will provide the greatest latitude for MEMS innovation and market growth?

BL: I personally think that generalized AI is still a way off, but the capabilities of deep learning system are so impressive that they almost seem magical. Deep learning systems use vast amounts of data to train DL algorithms to vastly improve speech recognition and other tasks. One trend of major importance that has been missed by the mainstream technology industry is how fast the amount of data generated by sensors will grow and how ubiquitous they will become. DL researchers should consider that the total data generated by sensors is increasing exponentially and this has huge implications for DL. Data is becoming the world’s most valuable commodity and sensors make data. The total amount of data generation will soar.

AR is an interesting market although we still need to figure out the dominant form factor; phones or head mounted. I think hearables are a market poised for rapid growth and that, as a smartphone accessory, can reach smartphone levels of volumes. VR, drones, robots and autonomous cars are all interesting, but will not approach smartphone volumes in the near term. The smart home and IoT can achieve huge volumes, but it will take time.

MD: What impedance, if any, do you see challenging the acceptance and use of more MEMS devices in emerging products and systems?

BL: At Vesper we are addressing two of the biggest obstacles, reliability and power consumption. Many new applications have small batteries and cannot continuously power active sensing and transmitting. Our ZeroPower Listening technology uses quiescent sensing to almost completely power down systems in the absence of the sensor stimulus. Also, many new applications need to last +10 years in any type of environment. Our inherent ruggedness addresses this.

The other major obstacle I see is that many smaller companies have good product ideas, but don’t have the internal engineering expertise in audio design or algorithm development. This is an industry wide barrier to wider adoption. Vesper’s strategy here is to partner with semiconductor and algorithm companies to develop turnkey solutions. So instead of burning engineering dollars on microphone location, a system developer can focus on their own unique value proposition.

MD: If you can speak about it, what do you and your award-winning design team have in the works at Vesper?

BL: Right now, we are focused on expanding our microphone product line to address more applications. Digital output and more varieties of ZeroPower Listening are coming very soon. Longer term, we are still investing in the core piezoelectric material and MEMS process to enhance energy transduction and increase SNR and other aspects of performance.

MEMS In A Nutshell

Based on our sit-down Q&A, we can walk away with some conclusions leading to aspirations. We can conclude that the need for custom design services, power consumption, and reliability are the main obstacles MEMS technology needs to improve and resolve. Another challenge, which appears to be industry wide as well, is the shortage of skilled engineers, creative designers well versed in the ways of MEMS.

In terms of aspirations, MEMS has the potential to solve many problems in almost every area from medical to aerospace. As we would say in Brooklyn, “it ain’t just audio man.” So, where’s that MEMS injection?

Just A Bit More

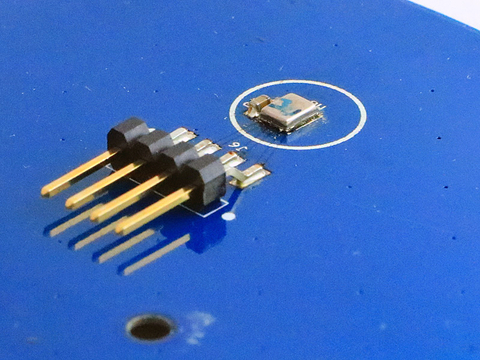

On the bootheels of the VM1010, Vesper has launched the VM2000 MEMS microphone for speech recognition. The device is a piezoelectric MEMS microphone that is immune to environmental contaminants, i.e., dust, water, humidity, oil, and particulate matter. According to the company, the component is highly stable. Its microphone arrays always stay in sync, ensuring consistent beamforming performance of the array.

Additionally, the VM2000 is immune to stiction, which causes complete voice-interface failure, and it offers reliable RF protection and dynamic range. Other features include ultra-low noise, low part-to-part variation, wide dynamic range, viability as a drop-in replacement for existing capacitive MEMS microphones, and a compact package measuring 3.76 mm x 2.95 mm x 1.1 mm.

About the Author

Mat Dirjish is the Executive Editor of Sensors magazine. Before coming on board, he covered the test and measurement and embedded systems market for Electronic Products Magazine, after which he spent thirteen years covering the electronic components market for EE Product News and Electronic Design magazines. He also has an extensive background in high-end audio/video design, modification, servicing, and installation.