Frameless resolvers and ring encoders are usually the engineer’s first choice for accurate angle measurement of large diameter shafts. As soon as a shaft or through bore diameter is larger than 2 or 3 inches, the choice of angle sensor shrinks and price increases sharply. This can lead some engineers to ‘indirect’ arrangements using a small shaft encoder, driven off a large shaft through gears or pulleys. Such arrangements can work well if requirements for precision or dynamic motion are modest but high-performance motion control will need direct measurements from a large bore or hollow shaft angle sensor.

This article discusses frameless resolvers and ring encoders; compares their merits and suggests an alternate approach. It’s particularly relevant for engineers designing gimbals and electrical actuation systems for high performance motion control.

Frameless Resolvers

A resolver whose axial height is small compared to its diameter, can be referred to as either a frameless resolver, a slab resolver or a pancake resolver. Strictly speaking ‘frameless’ simply means that the resolver’s housing has been eradicated but many engineers will use the term frameless when referring to a resolver with low height and big diameter.

Nowadays, most resolvers are brushless rather than brushed, but are all based on transformer principles. In other words, they are inductive angle sensors. As the position of a resolver’s rotor varies relative to its stator, the electromagnetic coupling between the rotor and stator varies. This be the resolver’s output signals vary relative to the excitation or input signal.

Some resolvers are termed ‘single-speed’, ‘two-speed’, ‘four-speed’ etc. This refers to the number of times that the resolver’s output uniquely varies over 1 revolution. A single speed resolver’s output is unique over 1 rev; a two-speed resolver’s output is unique over any 180 degrees within 1 rev; a four-speed resolver’s output is unique over any 90 degrees within 1 rev and so on.

Resolvers have an excellent track record in safety related applications – notably in civil aerospace. There are various reasons including non-contact operation; insensitivity to environmental conditions and ‘friendly’ failure modes.

In many safety-related or safety-critical applications, the most dangerous type of failure is not one which results in no output signal but rather one which produces a credible but wrong output signal. As an example, consider aircraft aileron control – a wrong but credible angle measurement could have catastrophic consequences. Given the construction and operation of a resolver, the probability of a failure which produces a credible but wrong signal is vanishingly small.

Resolvers will be the first option for many older generation engineers in the aerospace, defense, oil & gas sectors because they know the resolvers’ track record as well as the corresponding AC analogue electronics. Some knowledge of analogue electronics is required to specify and select the electronics required to power a resolver and decode its signals in to a digital format. Younger generation engineers are more familiar with digital electronics so they will struggle to specify a suitable resolver.

The perceived complexity of analogue electronics has been a significant factor in the demise of resolvers since the 1990s. This has led to a gradual reduction in the number of companies producing resolvers and an increase in the number of companies producing optical encoders.

Perhaps surprisingly, this reduction in availability of resolvers has led to a disproportionate increase in their price and of large diameter resolvers. Lead times of >6 months are not uncommon for high specification resolvers in the aerospace and defense sectors.

Advantages:

- Reliability; Robust

- Wide environmental operating envelope

- Accuracy (in multi-speed arrangements)

Disadvantages:

- High Cost; Heavy; Bulky

- Complicated electrical interface

- Limited availability, Tight installation tolerances

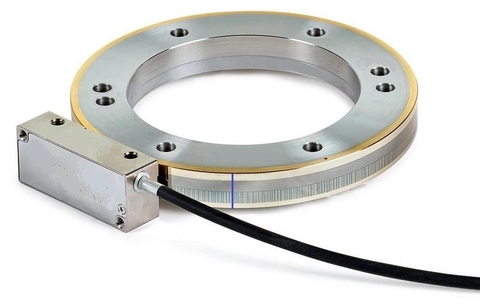

Ring Encoders

Ring encoders are also known as large hollow bore encoders or large through shaft encoders. As with frameless resolvers – all such terms refer to an encoder whose axial height is small compared to its diameter.

An angle ‘encoder’ is strictly defined as a device which translates (i.e. encodes) angle or change in angle in to an electrical signal. Although this may be true, the term ‘encoder’ is thought by many engineers to mean an optical angle sensor that produces a digital signal, most usually in the form of pulses. Whilst incorrect, nevertheless, most large bore encoders do use an opto-sensor as the basis of their measurement. Typically, a read head shines light on to an optical grating arranged around the periphery of a ring. The grating modifies the light reflected in to the read head’s opto-sensor and the pattern of light indicates angle or change in angle of the ring relative to the read head.

Modern etching or printing technology can produce microscopic features repeatedly on the optical grating. In turn, this allows optical encoders to offer theoretically high angular measurement performance. This sensitivity acts as both an advantage and disadvantage. The advantage comes from the optical sensor’s ability to measure small changes in angle – in other words, high resolution measurement – but the disadvantage comes from the potential for dirt or foreign matter (notably water and condensation in particular) interfering with the optical signal and causing a misread. The sensitivity of high resolution opto-sensors typically also limits their environmental envelope and they are generally not suited to applications with extreme temperatures or high shock and vibration.

More practically, the high measurement performance stated in the datasheet requires such tight installation tolerances that the claimed accuracy figures are unattainable unless two read heads are employed (and paid for). This is often not realized by many engineers until the angle encoder is compared against a higher accuracy calibration system.

Advantages:

- Accuracy (in arrangements with multiple read heads)

- Widely available

- Easy (digital) electrical interface

Disadvantages:

- Sensitivity to dirt and moisture

- Tight installation tolerances

- Restricted limits for temperature, shock & vibration

Inductive Encoders

Inductive encoders – or more commonly ‘incoders’ – use the same fundamental physics as resolvers but offer the same digital electrical outputs as an optical encoder. This means they offer the same robustness and reliability as a resolver but with an easy to use, electrical interface.

Unlike a resolver, all the electronics required for operation are inside the incoder’s stator. This means that the electrical interface is typically a low voltage DC supply which produces a digital data output representing absolute angle or change in angle.

Unlike a ring encoder, the incoder’s measurement is not just made at one point but rather across the full planar faces of rotor and stator. This means that incoders are much less susceptible to inaccuracies from non-concentric rotation, thus making their installation relatively easy.

Incoders are particularly well suited to applications such as gimbals and turntables where low axial height is required as well as a large through bore.

Incoders are available in absolute and incremental formats with high resolution digital outputs (up to 4million counts per rev) such as SSI, SPI, BiSS-C and A/B pulses. Some devices are also available as replacements for potentiometers with 0-5V and 0-10V outputs.

Advantages:

- High accuracy without tight tolerance installation

- Easy to specify and use; Insensitive to dirt & moisture

- Proven track record

- Less costly than optical encoders or resolvers of equivalent performance

Disadvantages:

- Higher cost than the very cheapest optical encoders

About the author

Mark Howard is a co-founder and the Managing Director of Zettlex. A mechanical engineering graduate with a master’s degree in systems engineering, he has spent much of his 30-year career in international sales and marketing. For more information or to discuss your application with a position sensor expert, contact Zettlex directly or speak with your nearest local representative. Chicago Office 1603 Orrington Avenue, Evanston, 60201, USA. Contacts: Mark Howard or Darran Kreit Email: [email protected] Telephone: +1 (847) 563 2314 Web: www.zettlex.com.