The Human-Appliance Relationship

How we interface with our home appliances has changed dramatically over the years. Clunky knobs and switches have been replaced by sophisticated, and sometimes not so sophisticated, touch controls and more elegant control panels with attractive visual displays and indicators. But it's not only convenience that has improved. Cookers, for example, are now much easier to clean thanks to smooth surfaces and the elimination of control knobs that can gather grime behind them.

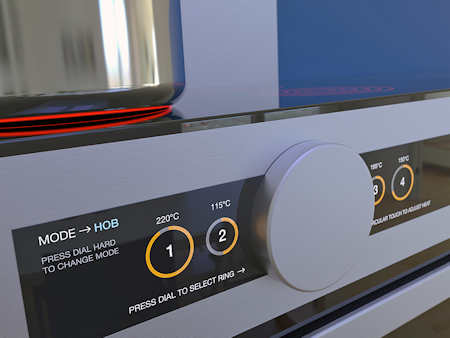

The more effectively we control our appliances, the safer they become. Accidentally turning them on can be disastrous, so some of the latest cookers adopt controls that require a firm press to switch them on and just a light touch to vary the temperature of hobs and ovens. Overall, the human machine interface (HMI) is evolving to become much more intuitive and less confusing, even as the functions available on appliances have become more numerous.

And there's more to this trend than usability. Electromechanical components such as knobs and switches are notoriously unreliable. They wear out and are the most common cause of breakdowns. If you can eliminate these components, the overall reliability of an appliance — one measure of which is mean time between failures (MTBF) — increases dramatically. That means fewer call-outs for manufacturers, less frustration for users, and greater protection for a brand's reputation.

Enter Force Sensing

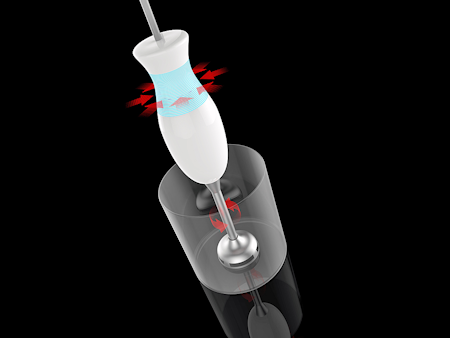

Force-sensing touch controls are on the ascendency. They have no moving parts so they're much more reliable and can let an appliance company know they're ageing, facilitating predictive maintenance. Force sensing has started to find its way into products like hand blenders, the speed of which can be controlled simply by squeezing the handle. But it's a tough call for appliance makers to figure out exactly what consumers want — they often don't know until they've experienced it, and then over a reasonably long period. Think about tablet computers. There was no obvious demand when Apple launched the iPad. Now tablets are everywhere.

This is why customer research rarely uncovers a demand for functions that don't already exist in some form or other. Product designers and developers therefore need to use careful judgment when creating HMI designs to help companies win market share. The risk is that their ideas are rejected by customers for being too different from what they are used to. Agility is the key here. If new concepts can be developed and tested with customers quickly, and then swiftly adapted in response to customer feedback, the companies that create them will win a competitive edge. Working closely with supply chain partners that share this agility is an essential requirement for success.

Next page

What's New?

So, what's the next technology breakthrough going to look like? QTC, or Quantum Tunnelling Composites can be used to create uniquely thin, responsive and reliable long-life buttons and controls.

QTC printable ink contains semiconductor particles in a polymer binder that leverage quantum mechanics to create a low-cost, flexible, force-sensing material. This material can be as thin as 50 microns, less than the average thickness of a human hair. The greater the force applied, the more quantum tunnelling effects increase electron flow through the polymer barrier, decreasing the resistance of the material from 100 KΩ to 100 Ω range. The pressure effectively transforms a dielectric into a conductor. Removing the pressure reverses the phenomenon with negligible hysteresis. What's more, there's no current flow when no pressure is applied, so it's a particularly energy-efficient sensing technology.

At their simplest, QTC sensors can be used as pressure switches or as potentiometers. No microcontroller is needed to decode intended touch, so the technology is both economical and easy to integrate into current designs. It may also unleash a wave of creativity in the next generation of user interfaces for appliances.

For example, QTC sensors can be used to create multi-function switches where setting or adjusting the control is a one-finger operation. It could be a circular outline on the smooth surface of a hop top or front panel that requires a firm press to switch the oven or hob ring on. Pressing the same button then sets the temperature, perhaps pressing the top part for up and bottom part for down. Press harder to make fast changes, or less forcefully for delicate, precision control.

Fig. 1: Force touch sensors can improve and simplify oven controls, giving a safe and intuitive user experience.

Users feel an instantaneous response when they touch even the most complex sensor arrays of QTC sensors. Low latency eliminates irritating uncertainty about whether the appliance has registered an intended action. It's something we often experience with poorly implemented touch and force technologies.

Next page

Acceptance Rising

There has already been some integration of display touch technology in a few domestic appliances, but not a holistic approach to the overall user experience. This is most likely due to the limitations of existing touch-sensing solutions, and the fact that capacitive touch works with a feather-light touch, offers no control through applied pressure, and performs poorly when the surface (or finger) is wet or greasy. These are not ideal characteristics for kitchen appliances that can become dangerous if users don't know when they're on or off.

Furthermore, today's product designers don't just want to map force. They also want to be able to detect the location of applied force so that they can sense several instances of gripping, twisting, or turning.

QTC sensors scan numerous touch points at the level of resolution needed for the application, from 1500 to 15,000 dots-per-inch or more. This multi-touch, multi-force capability opens up a vast range of options for those defining and designing new home appliances and consumer electronics products. At its most basic, multi-force is used to make current touch panels for stoves, ovens, microwaves, and blenders safer because the user has to press with a certain force level to activate a function.

When capacitive touch is used alone, accidentally turning on an oven is about as easy as pocket dialing someone — creating a material safety hazard if users don't apply a safety lock function that requires them to switch things on or off twice. Integrating force sensors is a simple fix for that problem.

Fig. 2: Both the function and form of domestic appliances is enhanced by QTC-based force sensors which can be used under ergonomically-curved surfaces.

The Penultimate Word

Finally, one of the most interesting uses of QTC-based sensors currently being evaluated by appliance manufacturers is integrating them with display technologies to create interactive and adaptable user experiences. By integrating with both curved and rigid flat displays, QTC force sensors greatly simplify button panels, scrolling controls, tumblers, grips and sliders.

Force sensing makes the surfaces more intuitive to use, and the displays enable user experience (UX) designers to simplify and improve the control surface layouts on many of today's appliances. Perhaps most importantly, force-touch display interfaces give brands the ability to create a 'signature' user interface – not only in look, but in the feel of its operation.

Appliance designers are only now starting to embrace true tactile sensing technologies like QTC, and it may not be long before we look back and wonder how we ever managed before the force-touch revolution transformed our relationship with electrical appliances and other electronic devices.

About the Author

Jon Stark is the CEO at Peratech, where he leads a team that's advancing the next generation touch technology solutions with Quantum Tunnelling Composites (QTC) technologies. He holds a BA in Political Science from the University of Rochester, New York.

Related Stories

Peratech collaborates to improve human-to-notebook PC interfaces

TE Connectivity Unveils Wireless Pressure Sensing Technology With Interactive Display

Sensors Enable Portable, Pro, And Private Percussion