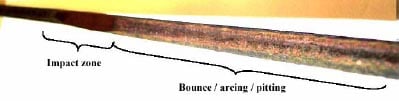

Figure 1. Scrape marks on contact wire, caused by pantographs bouncing due to low-tensioned contact wire |

Figure 2. Cause of vertical impact force due to pantograph hitting cross-span. This was due to low-tensioned OHTE causing abnormally high contact wire uplift |

Figure 3. Example of a kink that resulted in a severe vertical impact force. The arcing caused by the bouncing of the pantograph head as well as the wear caused by the impact force can be clearly seen |

By using force measurements, Spoornet found a way to successfully prevent catastrophic failures from occurring and recurring in the OHTE.

Some of the many benefits conferred by measuring the vehicle/infrastructure interaction contact forces include the ability to identify defective components. It has been estimated that 80% of the railway infrastructure life-cycle costs are spent on the maintenance and renewal phases. Any railway that wishes to reduce life-cycle costs must optimize maintenance methods and strategies. On the rail, commonly measured parameters include the gauge—the distance between the inner, running edges of the rail—and vertical and lateral alignment. On electrified railway systems the most frequently measured parameters are contact wire height and stagger, which is the perpendicular distance between the overhead conductor wire and the centerline of the track. These measurements are used to plan maintenance interventions.

However, you can't identify defective equipment or components solely from geometry measurements. Spoornet developed and implemented a force-based measurement system to detect faults on the OHTE that cannot be detected using traditional methods. The instrumented pantograph measured the dynamic interaction between pantograph and OHTE to study this complex interface. Measured data were used as input parameters into simulation models and the results from the dynamic simulations were used to optimize the OHTE and pantograph settings. In the process of conducting the research, both experimentally with the instrumented pantograph and theoretically with the simulation models, the company found that it could detect defective components or identify components in need of readjustment.

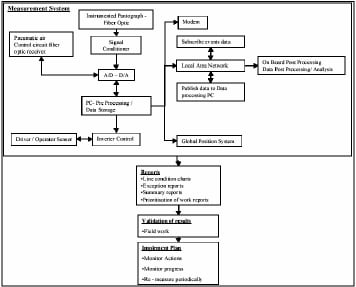

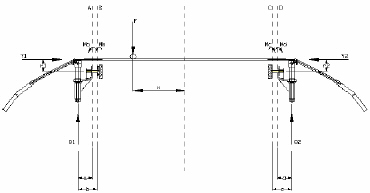

After this initial success, the company developed an overhead condition monitoring system to plan overhead maintenance. Figure 4 shows the block diagram of the system. The following parameters were measured: the triaxial contact force between the pantograph head and the contact wire consisting of the vertical (Q), longitudinal (L) and lateral (Y) contact forces (Figure 5), the contact wire height above the rail, and the stagger of the contact wire.

Figure 5. Free body diagram of pantograph head illustrating load cell position and input forces |

Special load cells needed to be designed and built to enable the measurement of these parameters. FISO Technologies fiber-optic strain gauges were bonded to the load cells to create the sensing element. The gauges, with their immunity to electromagnetic interference (EMI), their robustness, and their high sensitivity, gave accurate and repeatable measurements even when exposed to electrical and electromagnetic interference, mechanical vibrations, and climatic stress.

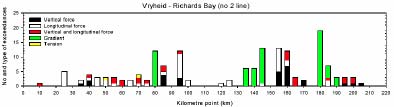

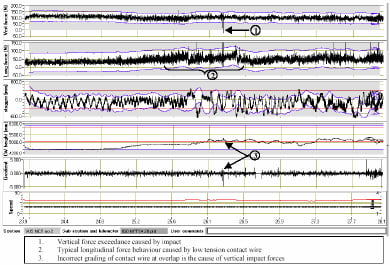

Three overhead condition monitoring systems are currently being used in the Spoornet network. The first is a 25 kV AC locomotive that has been specially modified and fitted with the measurement system. The second, a mobile system, can be fitted to any class of electrical locomotive operating in South Africa. A third system has been fitted to Spoornet's track geometry recording car. Once the measured data have been postprocessed, a detailed report, together with detailed graphical reports, summary graphs, and exceedance lists is compiled (Figures 6 and 7).

Figure 6. Example of a detailed graphical report showing some exceedances (Click image for larger version) |

To facilitate the interpretation of the measurements, the company developed software to process and display the data in real time. The program uses multiple threads to execute three functions simultaneously: data acquisition, processing, and storage; GPS polling and distance calculation; and monitoring of the control signals. An example of a summary graph is shown in Figure 7. This summary is used by the maintenance planner to prioritize scheduled maintenance. Glancing at such a summary, he can identify the locations that need priority corrective interventions. He can then refer to the detailed graphical summary to determine the exact cause/nature of the fault to prevent recurring faults. This allows the planner to efficiently schedule and allocate the resources that are necessary to perform the corrective maintenance at a particular location. The methods that have been developed can be easily extended to identify faults on the track structure as well.

FISO is represented in the U.K. by Sequoia Technology Ltd., Reading; +44 (0)118-976-9000, [email protected].