There is little disagreement that technology innovation continues to improve our lives on many levels. Socioeconomic trends are forcing changes that constitute actual opportunities for consumers, entrepreneurial companies of all sizes, and investors. In health care, an increasingly aging population means that the demand for health care services will continue to expand, and so will the pressure to find efficient ways to deliver those services. Discoveries in the life sciences that enhance the quality of life and extend its length continue to flow from research labs to the mainstream. Consumers want to take control of improving their health, and we have the technology that allows them to do so, including hardware, software, and cheaper-by-the-day data storage and access solutions.

In consumer electronics outside health care, the Internet of Things (IoT) is finally catching on in more tangible ways, due to improvements in interoperability. We are moving closer to implementing functional platforms where all our devices are connected as needed, and operate in harmony with each other. Smart home gadgets, smart cars, automation, augmented reality (AR), virtual reality (VR), connectivity, machine learning and its diverse applications, and more solutions for handling big data – all make for an exciting time to experience them all.

Following on these trends, emerging applications in medical, consumer electronics, robotics, industrial, and automotive markets increased the demand for simple, accurate, flexible, and low-cost sensing solutions. Researchers and engineers in academia and industry alike developed a dizzying array of sensors based on piezoelectric, resistive, capacitive, and optical techniques. This article describes super-capacitive Flexible IonTronic Sensing (FITS) technology, which meets the requirements mentioned above.

TacSense Inc. of Northern California developed flexible, transparent, pressure-sensitive ionic materials and structures embedded with a continuous conductive sensing layer. The resulting nanoscopic iontronic film (i.e. “ionic” + “electronic”) integrates seamlessly next-generation sensing technology with state-of-the-art microelectronics, and is ideally suited to pressure and force mapping applications of various surface topologies and geometries, for medical, consumer, industrial, robotics, and automotive applications.

Not only is the proprietary iontronic film flexible, ultrasensitive, and transparent - its fabrication process is also fully compatible with the industrial-scale manufacturing processes. Its response time is within a millisecond range, at least an order of magnitude faster than conventional flexible sensors. The overall device packaging can be as thin as 100 micrometers, with an optical transparency greater than 90%.

In a recent development, we configured an iontronic material into a thin-film capacitive sensing architecture for flexible and rapid response detection. Its interfacial capacitance relies on the formation of an electrical double layer in which electrons on the electrode and the counter ions from the iontronic film accumulate and attract to each other at a nanoscopic distance, which leads to an ultrahigh device sensitivity, more than a thousand times greater than that of the traditional solid-state counterparts. The sensor exhibits excellent repeatability even after more than hundreds of thousands testing cycles, and great thermal stability under temperatures varying from 25°C to 50°C.

To demonstrate its capabilities, we tested the iontronic film in different formats. Its flexibility and conformability makes it perfect for wearable sensor applications, as the iontronic film takes the shape of the curved and deformable body surface it touches. When attached to a smart watch, our sensor allowed us to record real-time blood pressure waveforms of a radial artery before and after a physical workout. We’ve also recorded the blood pressure waveform from a temple location. When integrated with fitness or other garments, the iontronic film can record a person’s breathing pattern with high accuracy. With the iontronic fabric easily mounted onto a fingertip, we could resolve raised dots characters in a Braille textbook.

In another medical application, a sensor array was incorporated into compression garments to measure the interface pressure distribution data in real-time, for periodic or continuous monitoring of interface pressure necessary to guide compression therapy for the management of chronic venous disease.

Consumer electronics such as touchscreens, touchpads, and biometric devices should greatly benefit from our iontronic sensing technology and its characteristics, including high electrical sensitivity, low power consumption, fast response time, compact circuit layout, and simple device construction.

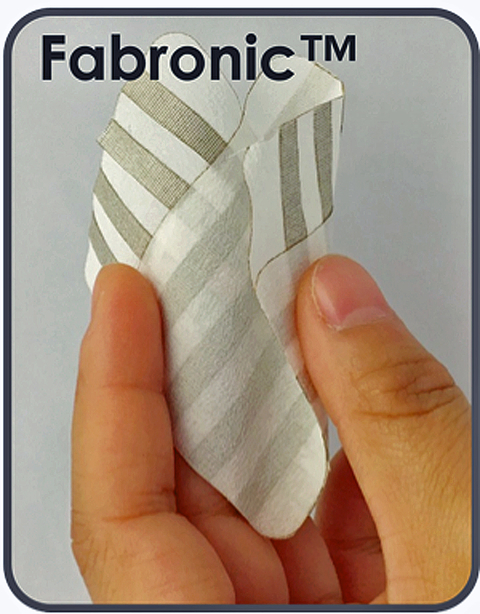

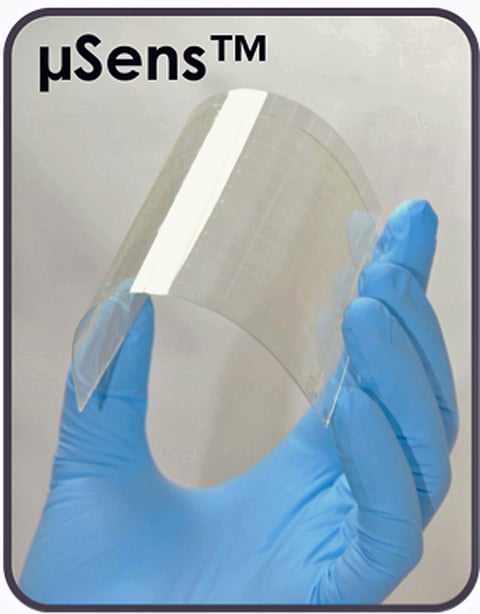

Currently, TacSense produces and markets sensors under its Fabronic (Fig. 1) and μSens (Fig. 2) product lines, with additional products in development. Our sensors are ready to be integrated into commercial products targeting areas such as sleep monitoring, baby monitoring, elderly care, vital signs monitoring applications, cardiovascular and other medical devices, robotic systems for dangerous environments, surgical robotics and other remote sensing applications, various consumer electronics, and infotainment systems.

automotive, wearables, and other consumer applications.

touchscreens, biometric devices, robotics, medical,

robotics, automotive applications, and more.

In closing, this article introduced what we believe is the world’s next-generation flexible pressure sensing technology with the highest sensitivity reported and discussed some of its applications.

About the authors

Gabriela Lee, MS, MBA, is a Business Development Consultant at TacSense Inc. She received her MS in Biomedical Engineering and MBA degrees from UC Davis. Contact info: [email protected].

Tingrui Pan, PhD, is the Founder and Chief Scientific Officer of TacSense Inc., and Professor in the Department of Biomedical Engineering at UC Davis. His research interests span a wide range of topics, including flexible sensing/ wearable technologies, microfluidics/ lab-on-a-chip, nanomaterials/ biofabrication, mobile and personalized medicine. Prof. Pan has authored over 100 articles in peer-reviewed journals and conference publications, and has over 20 US patents and patent applications. He received his MS degree in Biomedical Engineering, MSEE degree and PhD degree in Electrical Engineering, from the University of Minnesota. Contact info: [email protected].