As a systems integrator that services refineries and chemical plants in Louisiana, we find that the biggest maintenance headache our customers have is temperature sensor replacement. Rigid temperature sensors, used routinely inside thermowells for the past 20 to 50 years, are the nightmare of every maintenance department. Problems using rigid sensors include stocking difficulties, finding suitable replacements, ordering the correct length and size, and being unable to install a replacement sensor in an existing thermowell.

Flexible temperature sensors, on the other hand, offer a solution to these maintenance dilemmas. A flexible sensor fits nearly everywhere, can be cut to the correct length, and reduces the number of spare parts a plant has to keep on hand.

Rigid Sensor Challenges

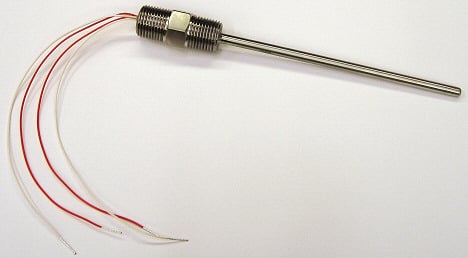

A standard rigid temperature sensor consists of a sensor element—thermocouple or RTD—protected inside a rigid SS shaft (Figure 1). These fixed-length sensors are either spring-loaded (for use with thermowells), welded to a hex nipple for a fixed immersion length into a process, or sealed with epoxy, exposing the sensor leads for external measurement connections.

Figure 1. A rigid temperature sensor incorporates a thermocouple or RTD and a SS shaft |

Typically, the thermocouple or RTD element is embedded inside the bottom 2 in. of a SS tube, which is then filled with mineral insulated powder (MGO) and sealed with epoxy to prevent moisture penetration. This assembly fits into the thermowell beneath the connection head. The wires from the sensor are terminated in the enclosed head and connected to extension wires using a terminal block or attached directly to a transmitter. Wiring is run back to the control room, usually encased inside conduit for long wire runs.

Normally, to replace a rigid sensor, a maintenance technician must follow several steps: remove the enclosure cap; disconnect the wires from the transmitter or terminal block; disassemble the union, conduit, and fittings attached to the transmitter and thermowell; and then move them out of the way before pulling the rigid sensor out of the thermowell. Depending on the age of the installation, the degree of corrosion on the conduit or junction, and the amount of room available, this can be an arduous task, particularly on the top of towers or columns, or in confined areas.

Determining the correct length of the replacement sensor can also be a problem. In many cases, a maintenance technician may know that the sensor needs to be replaced, but doesn't know the exact length of the rigid sensor. If the control loop involved is critical, the plant may not want to pull out the old sensor yet. Instead, they will make the necessary measurements first, order a new sensor, and wait for it to arrive.

In this case, the technician will have to make multiple visits to the sensor—first to determine as much information about the installation as possible, including sensor type, connection style (e.g., nipple union nipple, direct thread, lagging length, and approximate insertion length)—and then go back to stores to try to find a best fit, probably returning with a number of different sizes to avoid a third trip. Of course, the unused sensors then have to be returned to stores (another trip)!

In other cases, the technician leaves the old system intact, calls a sensor representative, and the two of them make an educated guess, based on a thermowell's length, size of the union, length of nipples, etc. At least one sensor manufacturer we deal with admits that they get it right only about 85% of the time when they have to guess. Alternatively, a maintenance tech can carry 8–10 spare sensors out into the plant in hopes that one of them will be the right size.

Maintaining proper documentation by recording the size and type of each temperature sensor for future reference could prevent these problems. However, this can be a daunting task, considering that some plants have hundreds if not thousands of temperature sensors. Plus, engineering drawings do not always represent the "as built" installation.

Once a replacement sensor is found, ideally it will simply slide back into the thermowell. Unfortunately, thermowells can cause other problems. Some thermowells will "sag" (bend) when exposed to high temperatures over prolonged periods, such as in flare stacks (Figure 2). While it may be possible to extract the existing sensor from a sagging thermowell, it is usually impossible to install a new rigid sensor into it. Instead, the thermowell itself must be replaced.

Figure 2. When exposed to extreme heat, thermowells can bend or "sag." You may be able to extract a temperature sensor from a sagging thermowell, but it is nearly impossible to install a new rigid sensor. A flexible sensor usually fits |

Thermowells can also accumulate debris. In areas with high humidity, such as in Louisiana and other southern states, thermowells can fill up with assorted contaminants that condense out of the air. When the rigid sensor is removed, this debris can then prevent a new sensor from being fully inserted back into the well.

Finally, the length of a rigid sensor can affect the accuracy of the measurement: A rigid sensor inside a short, 2–3 in. thermowell may not

Figure 3. A flexible sensor, such as the WORM from Moore Industries, slides into thermowells without requiring complete disassembly of the conduit, unions, and fittings. The sensor wires can be trimmed to fit almost any installation or application |

Flexible Solutions

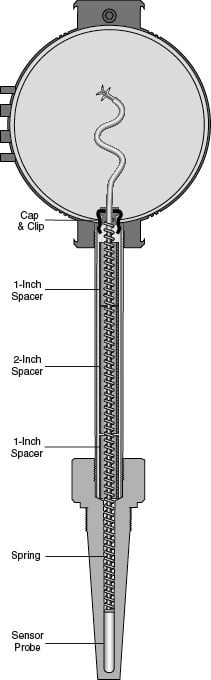

Even if an application specification calls for a rigid sensor, a flexible sensor can fill the requirement. A flexible sensor typically consists of a 1 in., SS sensor element and lead wires that are protected either with Teflon or with fiberglass insulation. The flexible sensor wires can be trimmed to the correct length depending on assembly (Figure 3).

A spring at the top of the thermowell holds the sensor element in place (Figure 4) and keeps the sensor in constant contact with the bottom

Figure 4. A flexible sensor includes a 1 in. thermocouple or RTD probe, flexible Teflon or fiberglass insulation, and a spring, which holds the sensor in place. If the wires must be rigid, spacers can be used |

Replacing a flexible sensor in the field is a much simpler proposition. The technician removes the cap, disconnects the sensor wires, removes the transmitter or terminal block, and pulls out the old sensor. It is not necessary to disassemble the union, conduit, or any other fittings. Because a flexible sensor can be trimmed to the correct length, a technician has to carry only a single sensor to the field. Flexible sensors typically are available in various lengths to accommodate nearly every size of thermowell or application.

In the case of a sagging thermowell, if the rigid sensor can be removed, a flexible sensor can be installed without replacing the old thermowell. We usually purchase flexible sensors that are slightly smaller in diameter than rigid sensors. The most popular rigid temperature sensors built in the U.S. have a 0.25 in. o.d. metal shaft. Most thermowells installed today have a 0.260 in. internal bore (7 mm in Europe). We order flexible sensors with a 6 mm o.d., slightly smaller than 0.25 in., making it easier to slide into a sagging well, or into dirty thermowells that have built-up or caked-on debris inside them.

Because a flexible sensor has a 1 in. sensor with flexible fiberglass or Teflon insulated lead wires and a spring, it can be trimmed to fit even the smallest of thermowells. And finally, since the spring and lead wires don't conduct ambient temperatures to the sensor, the outside measurement errors are eliminated. Like the tire plant noted earlier, we've had several applications on other flare stacks where, after installing flexible sensors, the process engineers were surprised to find that their stacks were operating at much higher temperatures than the previous (rigid) sensors had indicated. The resulting energy savings and reduced/lower fuel costs obtained from operating these stacks at the proper temperatures paid for the replacement sensors many times over.

Intriguing Applications Flexible sensors offer several interesting ways to approach temperature measurement applications and their problems. For example, the intense humidity in Louisiana causes "green rot" at the wire termination points with thermocouples, so engineers and technicians try to avoid as many termination points as possible. Because a flexible sensor can be made with any length of wire, we now have several plants in the area that do not use terminal blocks any more; instead, they run the wires directly to temperature transmitters located in a separate cabinet. The sensor wires run inside rigid or flexible conduit, all the way from the thermowell to the remote mounted transmitter, without using any intervening termination blocks. This eliminates one major source of failure.

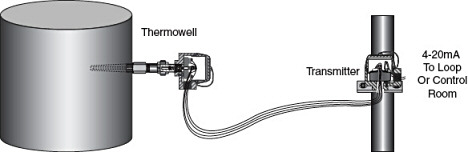

Another plant noted that since the sensor wire did not carry any dangerous voltage or current, encasing it inside conduit was unnecessary. Therefore, all their sensor cables run directly from the thermowell to a remote transmitter without conduit (Figure 5). The flexible insulation covering the sensor wires is sufficient to protect it from most environments, but SS braid or flex armor can be added at very little cost.

Figure 5. Some refineries are using flexible sensors without conduit. This allows them to install transmitters at the bottom of columns, tanks or towers |

In one application, a plant had a burner with dozens of temperature sensors, but none of them could be replaced without shutting down the entire burner. It was simply too hot for a technician to walk into the burner while it was operating. By using flexible sensors inside long protection tubes attached to the points of measurement, it was possible to slide a flexible sensor in and out of the tube from a safe location without shutting down the burner.

In a similar situation, a refinery had a problem calibrating and replacing sensors with transmitters located on top of columns or towers. It was physically dangerous to climb to such heights while the hot process was running, and to try to work with rigid conduit, fittings, and transmitters safely. The refinery replaced all its rigid sensors with flexible ones and installed the transmitters at the bottom of the towers for easy access. The transmitters could be calibrated or replaced from the bottom of the tower, and the flexible sensors were easier to change out if they failed.

During the last year, several refineries in Louisiana have begun systematically replacing all their rigid temperature sensors with flexible sensors because of the cost savings they expect to gain. Maintenance will be easier, take less time, and cause fewer shut downs or process interruptions. Fewer thermowells will have to be replaced because of sagging or foreign debris clogging the wells. Only two or three standard sensor lengths will be needed for an entire plant, reducing the spare parts inventory. They will get better measurements in shorter thermowell applications, leading to increased accuracy and energy savings.

Although conventional rigid temperature sensors have proven to be a workhorse in the field for the past 50 years, modern flexible sensors are now starting to replace them across Louisiana.