Engineers and industrial workers need equipment they can rely on, especially when conditions aren’t perfect. Mission-critical processes call for network components that can withstand interference issues, dust, vibrations and extreme temperatures. Many teams are turning to wireless networks that offer a reliable, robust and fully available communication method for a variety of application scenarios.

Wireless local area networks (WLANs) are critical to the modernization of the industrial workplace, allowing teams to operate more efficiently and transmit signals between a variety of ranges at different frequencies. Success with wireless starts with choosing an antenna that will transmit data signals no matter the circumstance. Antennas are typically grouped by frequency range:

2.4 GHz Frequency

- Short range: Up to 218 yards (200 m) with omni-directional antennas

- Medium range: Up to 0.62 miles (1 km) with sector antennas

- Long range: Up to 3.11 miles (5 km) with directional antennas

5 GHz Frequency

- Short range: Up to 328 yards (300 m) with omni-directional antennas

- Medium range: Up to 1.86 miles (3 km) with sector antennas

- Long range: Up to 9.32 miles (15 km) with directional antennas

Antennas serve as one of the most important pieces of a wireless communication infrastructure. The mechanical stability, extended temperature range, and resistance to corrosive materials these devices provide meet the requirements and throughput needs of most industrial applications and use cases.

A closer look: Different antennas for varied needs

Each specific scenario at hand will require a different type of antenna to get the job done. Directional antennas point radio frequency (RF) in a specific direction for RF concentration within a targeted area. Omni antennas provide equal coverage in all directions, with a coverage pattern that looks like a sphere.

For robust coverage in a designated space, especially when using point-to-point connections, directional antennas should be used to ensure the strongest possible signal. These antennas are best used to connect buildings or outdoor spaces via specific signals and angle openings. A wide angle is most effective for short distances, and acute angles for lengthy distances.

The omni antenna is better suited for open spaces because of its spherical coverage area. The actual coverage range depends on the antenna’s sensitivity, but teams find this type of antenna is also extremely reliable for indoor settings and open rooms.

Multiple In Multiple Out (MiMo) antennas are often used in conjunction with directional or omni antennas, and are supported by WLAN. These antennas consist of a single structure containing up to three single antenna elements, and work best in noisy surroundings.

Acing the test: Antenna applications

Applications vary and selecting an antenna that can hold up in its designated environment is very important. Each system type should be put to the test and held to a strict list of circumstantial and environmental conditions to prove its effectiveness and reliability. A variety of questions should be asked for each:

- Is the communication fixed between different areas, like a point-to-point link?

- Does the signal need to cover side areas, such as a factory floor?

- Are there clients (phones, laptops, tablets) that are moving, that need to have uninterrupted coverage of the whole area?

- As the client moves around, are small breaks in communications acceptable?

- What sorts of traffic types will be used in these applications – simple low data rates from programmable logic controller communication or high bandwidth high definition video? Both?

Industrial production areas are moving toward wireless networks to serve as both a remote-control system and a technology that can receive measurement data. These environments require robust, maintenance-free networks with reliable WLAN features ideally suited for applications in hazardous settings. To get adequate coverage in these environments, directional antennas are found to be the best option when mounted on a fixed, central site. For smaller production areas, omni-directional antennas are recommended for desired coverage.

In factory automation settings, tasks are performed simultaneously, meaning the same system used to control an entire factory must also be able to connect to the larger system, yet function individually on specified items. Selecting the right antenna for the application at hand ensures bottlenecks don’t occur.

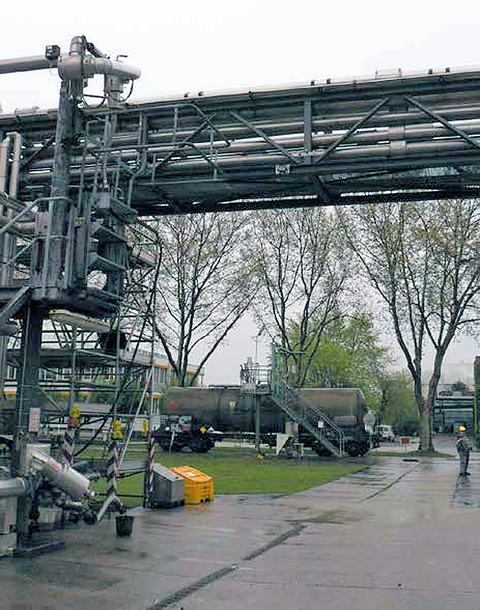

In the supervision of a large outdoor industrial production area, such as sand loading units for example, direct line of sight communication is necessary between where the signal is sent and received to clearly communicate information to the machines loading the units. In this case, directional antennas are the most effective option for transmitting reliable and effective signals over the larger desired coverage area.

Your network, your needs

There are a variety of business benefits that can arise when teams choose wireless technology as their network infrastructure of choice. These networks eliminate the need for local support and multiple workers assigned to one task by easing the set-up time required before and after production. Reliability ratings are also increased, with customers reporting 90 percent of cases have seen the reliability of WLAN match that of their cable connections. Cost savings from a solid wireless system fluctuate depending on the use, but often fall between 10-30 percent – and sometimes even more. By choosing an appropriate, reliable wireless network, teams can meet their unique business needs and objectives, ultimately moving the organization forward.

To learn more about wireless network communication and the different types of antennas required for specific applications, CLICK HERE.

About the author

Ciaran Burns has been with the Belden Competence Centre since Feb. 2014 and is now the vertical field application engineering manager for transportation, focusing on supporting the sales team to execute and manage complex projects in the EMEA region for Belden’s industrial platform. Ciaran’s other responsibilities include general application engineering in the UK and Ireland. Prior to this, he was lead technical member of the Belden solutions team. Ciaran gained seven years of experience in industrial automation and control at West Control Solutions, a Danaher Corporation company, with various technical and commercial customer-facing roles, including custom solutions project manager. Ciaran graduated in 2005 from the University of Sussex in Brighton, England, with a First Class Masters in electronic and communications engineering.