Look Ahead

Planning ahead is the key to successful design engineering involving magnetic sensors. Maintaining open communication with the original equipment manufacturer (OEM) team and the customer helps the design engineer address the unique parameters, requirements and constraints of the project (see table 1). The engineer should take a holistic approach to the design process, considering the full magnetic circuit, not just the sensor itself. This includes an examination of the magnetic actuator and surrounding environment in the near proximity to its location.

Table 1: The importance of communication in design engineering.

Significant challenges arise if the OEM does not consider sensor placement until after the main system design is almost completed. This failure to plan often results in a design characterized by very unique sensor design requirements that may not be met by an out-of-the-box sensor package. For example, the mechanical design footprint may not fit into the available space or the electrical load may not allow for a standard sensing element without extra circuitry. In addition, the environmental conditions within the application may be extreme. If a standard sensor will not address these unique requirements, then a custom sensor is needed.

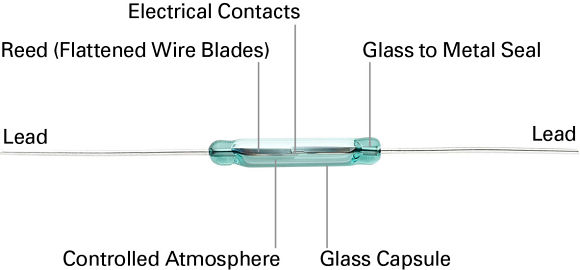

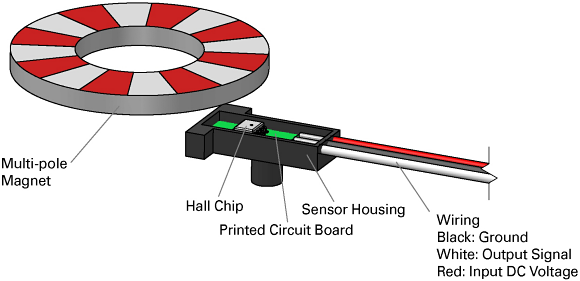

This article will discuss four key parameters that design engineers should consider when specifying a custom sensor: environmental, mechanical, electrical, and magnetic. These guidelines are especially useful since they can be applied to any magnetic sensing application involving reed switches or Hall Effect sensors (see figures 1 & 2).

Fig. 1: Components of a Reed switch sensor.

Fig. 2: Components of a Hall effect sensor for a speed sensing application.

Environmental: Plan Ahead for Extreme Heat and Moisture

There are several environmental factors that could impact the performance of the magnetic sensor. Understanding the effects of each one will help the engineer take precautions to ensure the integrity of the circuit design.

Temperature

Operating and storage temperatures that exceed +100°C could degrade the performance of the sensor and magnet. Hall effect sensors have maximum temperature limitations ranging from +85°C to +150°C. Once the maximum temperature value is exceeded, the sensor loses its calibration and will not respond properly to the magnetic field. Reed switch performance is minimally affected by temperatures up to +150°C. The final section on magnetic parameters provides more details on how temperatures impact the selection of the actuator's magnetic material.

Humidity

This greatly influences the selection of the magnetic material and the potential coating, if required, for the magnet. Some magnet materials such as neodymium are very sensitive to moisture and can disintegrate because the iron degrades with moisture.

Shock and vibration

These should be reviewed closely. Reed switches can be negatively affected by high G forces and could require special orientation of the blades.

UV

For outdoor mounting, the plastic material under consideration for the sensor should be able to withstand prolonged UV exposure. The engineer should check to see if there are any special validation performance criteria required.

Thermal Shock

A thermal shock test is recommended to validate the sensor design and ensure its long-term performance. This test is usually conducted if there is a wide temperature range such as -40°C to +105°C. The high temperature may even reach +150°C. If packaged improperly, the materials can degrade under high stress. The thermal expansion coefficients for plastics and potting materials should be analyzed to ensure their compatibility with the switching component within the sensor across the full temperature range.

Mechanical ~ Understand the Orientation, Alignment and Connection Requirements:

The design engineer should review the 3D CAD model showing the area where the sensor and magnetic actuator will be located within the OEM system. This will help the engineer select the optimal sensor and magnetic actuator design to fit within the available space. To understand the mechanical constraints of the application, design engineers should ask themselves these questions:

- Is there a specific orientation of the sensing device that may influence the package design and mounting method?

- Is there space available for both the sensor and the actuator? Are there dimensional constraints involved?

- Does the required activation and deactivation distance between the sensor and actuator allow for the proper orientation of the magnet to the sensor?

- Does the customer require a special connector (i.e., a sealed type or termination) that is compatible with the mating harness or circuit board? (The wire insulation type is important when considering the temperature or chemical environments that the sensor may be subjected to. A surface-mount device could be considered for circuit-board mounting.)

- Are there special materials that should be considered for meeting the mechanical requirements? Thermoplastics and nonferrous grades of metals are common materials for housing magnetic sensors such as reed or Hall effect sensors.

In addition, potting materials are needed to protect reed and Hall effect switches. There are many grades of epoxies or urethanes available for potting materials. Epoxies are usually the preferred choice for sensor protection because of their stability over a wide range of temperatures.

Electrical ~ Consider the Load, Switching Cycles and Output:

To fully understand the electrical factors involved, design engineers should ask themselves:

- What is the electrical load that is being switched?

- What is the switching voltage and current?

- Is it AC or DC? Is it a logic-level load?

- Is the circuit powered by a battery? If so, what is the battery voltage value?

- Is the switching load resistive, inductive or capacitive?

- How many switching cycles over the lifetime of the product are required?

- Are there any special switching speed requirements (i.e., for speed sensors)?

- Which type of sensor output does the customer desire: digital or analog?

- Does the customer want a normally open, normally closed or single-pull-double-throw reed switch?

- Are there any special requirements such as EMC, EMI or ESD considerations within the application? (This is very important when using a Hall effect sensor.)

Magnetic ~ Assess the Material, Quality and Performance:

Unfortunately, the magnetic actuator is often overlooked when specifying a reed or Hall effect sensor. This is especially surprising since the magnet and sensor each make up 50 percent of the final design of the magnetic circuit.

The OEM customer may say that he or she already has a magnet designed into the application without considering the possibility of technical issues. To prevent issues, it is important for the design engineer to review the magnet's design with the customer for the required application. This thorough analysis of the magnetic circuit will prevent long-term quality issues during production.

The engineer should use this list to assess the quality and performance of the magnet:

- Use magnetic simulation software to gain a thorough understanding of a sensor's magnetic operating environment under a wide range of conditions. This tool characterizes sensor performance while operating and interacting with magnetic fields in motion. It should consider any ferrous metals located near the sensor and magnetic actuator assembly that could shunt the intended magnetic field away from the sensor. This simulation should be done prior to investing significant time in benchtop testing and tooling.

- Consider the temperature of the application since it has the most impact on the magnetic material. Some magnetic materials such as neodymium have limitations on the maximum allowable operating temperature. Once the maximum temperature has been exceeded, the flux density significantly decreases and cannot be reversed. For benign environments such as indoor applications, an alnico magnet or a low-cost ceramic magnet may work well if the material meets the required distance tolerance for sensor activation. In a high-temperature application with many fluctuations in temperature (i.e., an automotive environment), a very stable rare earth magnetic material such as samarium cobalt is often required.

- Study the magnet's polarity and orientation. A Hall effect sensor typically operates using only the north or south pole of the magnet. A reed sensor is not polarity sensitive and will operate with any magnetic pole.

- If an activation tolerance is quite tight, eliminate the ceramic grades and alnico grades, while recommending a neodymium or samarium-cobalt magnet. The rare earth materials are much more cost competitive than in previous years.

- Be very careful of using a neo-grade magnet when the application is within a high-moisture environment. Nickel plating over neodymium is a good barrier. However, it is not a guarantee that moisture will not penetrate under the nickel through a crack. Select a samarium-grade material for this environment if a rare earth material is required.

- When packaging the magnet in a sealed plastic or nonferrous metal package, neodymium may be considered for a high-moisture environment.

- To prevent price from becoming a future issue, make sure the magnet material is not over specified for the application.

Conclusion

When it comes to designing magnetic sensing applications, advance planning and open communication are vital for success. The design engineer must fully understand the parameters, constraints and requirements before starting project development.

If sensor placement is not considered prior to the application design, a custom sensor may be required to address the unique requirements of the application. Considering the environmental, mechanical, electrical, and magnetic parameters for the application ahead of time will help the engineer select the optimal custom sensor, resulting in an accurate and effective design.

Part II of this article will discuss how to select the best magnetic sensing technology for a specific application.

About the Author

Gwenn Gmeinder is the North American Business Development Manager for sensor products within the Electronic Business Unit at Littelfuse. For over 30 years, he has worked with sensor technologies at several companies. Gmeinder joined Hamlin in 1978 as a product design engineer and began managing its global business development in 2007. He has held his current position within the company - now part of Littelfuse - since June 2013. Gmeinder earned his BS in industrial technology from the University of Wisconsin-Stout. He can be reached at [email protected].

Related Stories

Ten Easy Things to Do with Magnetic Sensors

Using Magnetic Sensor ICs In Highly Magnetic Environments