Energy harvesting has been steadily gaining interest in the technology sector, but without useful applications it will remain just an intellectual curiosity. The continuously decreasing power requirements of electronics, however, have increased the number of applications for which this technology can be used effectively. One such application is the wireless sensor system.

The key to making energy harvesting useful for powering wireless sensing applications is the ease with which the technology can be incorporated into sensing devices. For example, a designer of an energy-harvesting-powered wireless sensor does not want to deal with the hundreds of volts being output by a piezoelectric device. Sensors need a standard DC voltage to directly power their operation. Furthermore, the energy-harvesting device must also produce and store adequate energy to perform the desired sensing task in a reasonable form factor.

One Solution

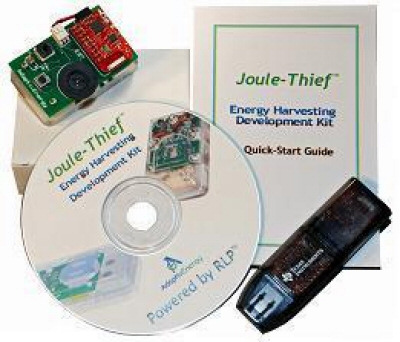

A product that meets these requirements is AdaptivEnergy's Joule-Thief energy harvester (Figure 1), which uses the proprietary Ruggedized Laminated Piezo (RLP) material, to harvest vibration energy efficiently. The highly engineered material is based on a piezoelectric ceramic that has the unique property of changing shape in the presence of an electric field. This occurs when an atom—centrally located in each unit cell in the ceramic—shifts slightly due to the imposed electric field, distorting the cell. The distortion of many cells in the ceramic leads to a small deformation, or strain, of the bulk ceramic.

Figure 1. AdaptivEnergy's Joule-Thief energy-harvesting module |

RLP takes this small motion and mechanically amplifies it to produce larger displacements. Conversely, when a piezoceramic is strained by an externally applied force, the cells in the ceramic are deformed slightly, which shifts the central atom and leads to a tiny polarization of the unit cell. The sum of the polarizations of many cells leads to a net polarization of the ceramic. If electrodes are placed on each side of a piezoelectric plate, the net polarization produces a flow of electrons, or electric current, which can be captured and stored to power electronic devices such as wireless sensors.

To produce a piezoelectric energy harvester with the greatest power density, AdaptivEnergy engineers start with a high-quality piezoceramic material. Using computer modeling and a proprietary lamination process, they engineer the stress state in the piezoceramic to be uniform in magnitude during operation. The optimized stress state leads to a significant increase in power output because all the ceramic is contributing to the production of energy. The result is that the Joule-Thief produces very high power output per unit weight and volume (Figure 2). The RLP's power output is such that it can be scaled to small footprints to produce compact energy-harvesting devices.

Figure 2. Raw power output of the Joule-Thief RLP versus competitive harvesting beams (Click image for larger version) Figure 2. Raw power output of the Joule-Thief RLP versus competitive harvesting beams (Click image for larger version) |

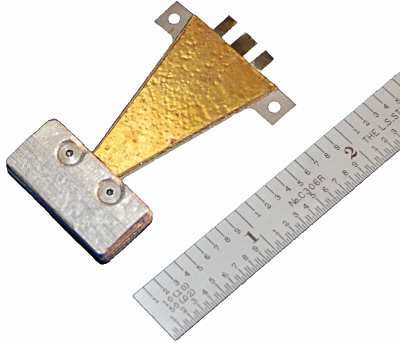

The fabrication process produces a rugged device that can survive high impulse and shock inputs, with the Joule-Thief RLP energy-harvesting beams (Figure 3) having been driven to >60 G without failure. While testing of the RLP is ongoing, it is anticipated that its reliability will be similar to that of an RLP actuator that has been tested to >150,000 hr. MTBF. Joule-Thief technology also offers advantages over batteries, with improved performance at extreme temperatures. Batteries tend to perform poorly at temperature extremes, particularly cold temperatures. While temperature does affect the output of the RLP, the effect is minimal within the range of –20°C to 100°C (Figure 4).

Figure 3. AdaptivEnergy RLP energy-harvesting beam |

Figure 4. Typical effect of decreasing temperature, which reduces the effective storage capacity of many lithium batteries |

Efficient energy collection is vital to making energy harvesting a viable technology. To complement the high output of the RLP, AdaptivEnergy engineers have designed electronics to efficiently capture and store the energy produced. While the circuit design is proprietary, the efficiency of the design can be traced to the use of ultra-low-power components. The Joule-Thief offers several options for energy storage, including capacitors and lithium batteries. A version with the latest thin-film lithium-ion battery technology is being evaluated. The goal is to provide appropriate energy storage means for the customer's application.

Paradigm Shifts

It is hard to determine if it is the emergence of new technology or the evolution of application requirements that brings change. In both cases, end users often must alter the way they look at operating requirements and opportunities. For example, powering sensors with energy harvested from ambient sources requires a paradigm shift in how electronic devices are powered. If continuous operation of an electronic device is not necessary, then the average power output of an energy-harvesting device is not the metric of concern. AdaptivEnergy encourages customers to "think joules, not watts" because the important criterion is the amount of energy needed to perform the customer's task, not how much power can be generated. Once this is understood and the amount of energy collected by the device is known, it becomes a simple task to determine how much data can be collected and how often a transmission can be made.

The same technology that allows for power-autonomous sensing devices also ushers in new application opportunities. In this case, wireless sensors are being deployed with increasing frequency where the installation of wiring is not a viable option. A good example of this is the use of sensors to monitor the health of machinery. Wireless sensors allow more machinery parameters to be monitored simply because their installation and maintenance requirements are relatively palatable compared with their hard-wired cousins. In addition, they make it possible to avoid unscheduled downtime, to limit maintenance only to times when it is required, and to reduce operating and maintenance costs.

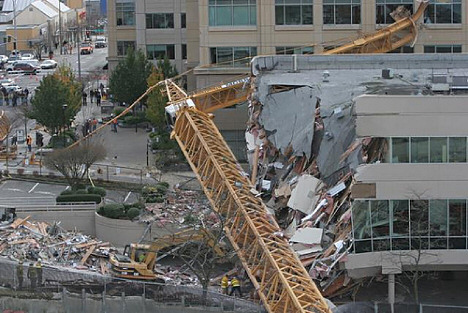

Another application of energy harvesting and wireless sensors is structural health monitoring, a hot topic after the collapse of the I-35W Mississippi River Bridge in Minneapolis, Minnesota, and the collapse of the construction cranes in New York City (Figure 5). This application genre also includes aircraft. In this industry, when the expense of installation, maintenance, and the fuel required to carry the additional weight of the wiring is taken into consideration, the cost per foot of wire can approach $2000. Furthermore, in many aircraft applications, the sensors are simply too difficult to reach to change the batteries. And even if it were possible to reach the sensors, the cost of the labor to purchase, store, and change a battery far exceeds the cost of the battery itself. The ultimate goal of aircraft manufacturers is to embed sensors in the structures during fabrication. Automobile manufacturers face similar challenges, particularly with the high price of gasoline. The increase in fuel efficiency enabled by reductions in vehicle weight has led auto manufacturers to consider wireless sensors and switches to help reduce wiring harness weight in vehicles, which now weighs up to 500 pounds.

Figure 5. Structural health monitoring applications, such as monitoring the structure of a crane, are well served by energy-harvesting-enabled wireless sensors |

Predictions and Trends

These tactical paradigm shifts herald broader changes. For example, perennial futurist Ray Kurzweil predicts a day when "ambient intelligence" will enhance the way people interact with their environment. In Kurzweil's world, sensors will be scattered around like dust to sense everything in the environment and provide feedback to improve our lives and safety. This multitude of sensors will likely not be battery powered. With microcontrollers and sensors in more and more simple electronic devices (e.g., refrigerators, washing machines, and coffeemakers), it's beginning to look as if Kurzweil's vision of the future may be correct. The smart home of the near future will be filled with sensors, and it's anticipated that energy-harvesting devices that can power the sensors will play an important role in their future.

Another fact that Kurzweil likes to point out is that technology improvements tend to follow exponential trends. For example, Moore's law predicts the number of transistors on an integrated circuit will double every two years. This prediction proved accurate, and the trend continues to this day. Similar exponential shifts can be expected in the size and power requirements of electronics, where devices become increasingly smaller and require less and less energy to operate. Paralleling these shifts, the capacity, or energy density, of energy-harvesting technology, such as AdaptivEnergy's Joule-Thief, will increase exponentially. When the impacts of these trends converge, a new world of energy-harvesting-powered electronic devices will become feasible and more and more self-powered electronic applications will become part of our daily lives.

Today's Products

The commercialization of AdaptivEnergy's energy-harvesting technology (see sidebar "Test Drive Power Harvesting") began with a project for In-Q-Tel, the venture capital arm of the U.S. intelligence community, but AdaptivEnergy's customers are now exploring a wide range of applications for the Joule-Thief beyond wireless sensing. In fact, the technology is being evaluated in applications as diverse as machinery and structural health monitoring, vehicular sensing and switching, and asset tracking.

As power requirements for electronics continue to decrease exponentially, and the power output of energy-harvesting devices continues to increase exponentially, more and more self-powered electronic applications will become feasible. A question often asked is "Can you power my cell phone or MP3 player?" Maybe not today, but that day is coming, and it may not be too far in the future. In the meantime, powering wireless sensors appears to be an ideal application for energy harvesting.

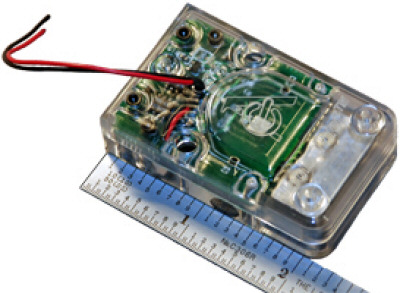

| Test Drive Power Harvesting For evaluation purposes, AdaptivEnergy offers a vibration-powered Wireless Sensor Demonstration Kit (Figure 6) in which five sensing devices, a Texas Instruments MSP430 microcontroller, and a Texas Instruments CC2500 wireless radio are powered entirely by a vibration source. All the sensor data can be transmitted approximately once per second with the included vibration source, or every five seconds with vibration amplitudes in the tens of mg. For those unfamiliar with vibration amplitudes, this represents a vibration that is barely perceptible to human touch. If longer durations between transmissions can be tolerated, it's possible to power the device with imperceptible vibrations.

To specify energy-harvesting material for a wireless node, you need to know the frequency and amplitude of the source vibration, the energy required to perform a transmission, and how often a transmission must be performed. |

RLP and Joule-Thief are registered trademarks and trademarks, respectively, of AdaptivEnergy LLC.