These days we all carry electronics around with us. Sometimes even a bit too much. So imagine if you could integrate some of these functions into the clothes you wear. This article shows how to produce flexible and stretchable clothing fabric that incorporates electronics. And who knows, maybe in a few years these textiles will be starring on the catwalk in sports, health, and safety clothing.

Why should we integrate electronics into clothing?

Ask an expert in wearable electronics about the future and he'll start dreaming about sensor bracelets, smart glasses, heart-monitoring patches and so. These dreams almost make our so-essential smartphone pale into insignificance. Because clothing and textiles are certainly not to be overlooked. In fact, they make the ideal platform for wearable electronics.

That's because clothing has many advantages over the examples mentioned above. First of all, clothes are something you have to wear anyway. You can forget your smartphone or sensor bracelet, but you won't forget to pull on a T-shirt or other garment. A second advantage is that clothing covers your whole body. This is important if you want to wear sensors that monitor your health or display lights that make you visible when you're riding your bike in the dark. And, finally, clothes help to make technology become invisible. For example, you can't see that you're wearing a heart monitor if it's integrated invisibly into your T-shirt.

Easier said than done

While you can already find examples of smart clothing on the market, it's still only a tiny taste of what is going to come. The smart clothing you find today still uses standard electronics in rigid form. Also, it includes tight-fitting clothing when sensors are involved. But if you're a heart patient, you probably don't want to wear a tight sensor T-shirt every day. Plus, at the moment, the functionality of smart clothing is still very basic. It can only get better.

Holst Centre kicked off the 'Smart Garment' program in 2014 because the researchers there believe that they have the technology needed to take smart clothing to a higher level. However, it promises to be anything but a straightforward exercise.

If you are going to incorporate electronics into fabrics, the material itself must not lose its intrinsic properties. If your T-shirt doesn't feel soft and the fabric can't breathe, or if it doesn't fall nicely round your body and you can't wash it, then you won't wear it for very long. And if it's expensive as well, you won't buy it in the first place. So we have to develop a technology that enables us to make inexpensive, thin, flexible and stretchable electronics that can easily be integrated at various locations on the garment. And not just one type of electronics, but various functionalities: visual displays, LEDs, sensors and actuators, antennas and radios for wireless connection, switches and so on.

Foil with printed electronics

Holst Centre is developing system-in-foil (SiF) technology, which enables electronics to be printed on large sheets. This is of interest for solar cells and for RFID tags that have to be integrated into packaging, as well as for smart clothing. Jeroen:

Using SiF technology you can produce thin, flexible and inexpensive electronic foil sheets. You start with a polyester sheet just 25 to 50 micrometers thick. You then 'print' your electronics on it. This is the ideal technique if price is important and you want to work with large surface areas. The polymers applied through the printing process are also flexible, which means that the foil retains its intrinsic properties. Working like this, we have been successful in producing circuits with multiple layers (four, to be precise), as well as passive components, sensors, OLEDs, and solar cells. Of course, it's not possible to print everything, which is why it is also important to develop a good integration technology enabling you to work standard components such as LEDs and microcontrollers nicely into the foil. This is something else we have demonstrated successfully.

Next page

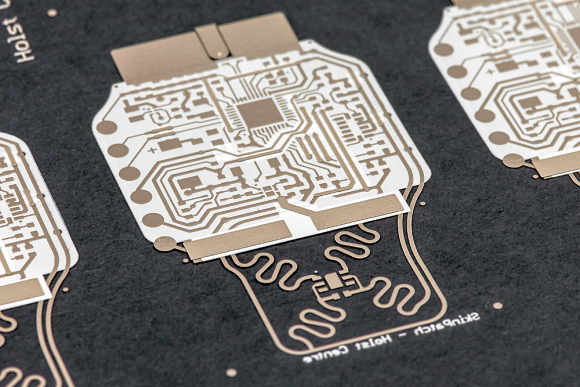

Fig. 1: A printed circuit consisting of multiple layers. This result is achieved by using alternating conductive and insulating inks. This circuit has 4 layers. The focus is now on 6-layer circuits.

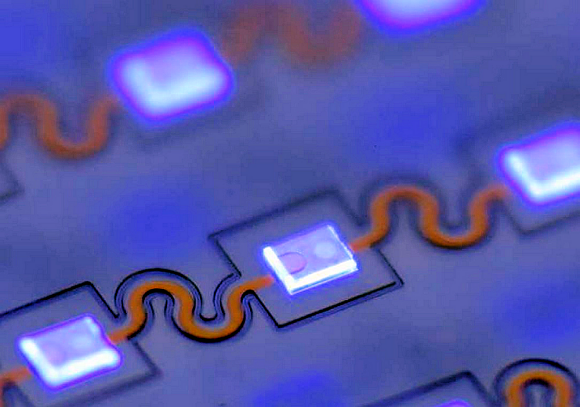

Fig. 2: Heterogeneous integration of LEDs into foil.

Can we add a little more stretch?

Foil with printed and integrated electronics may be flexible, but it's not stretchable. And if you want clothing that's pleasant to wear, you need a bit of stretch.

At imec's associated lab of the University of Ghent they have developed a technology that makes electronics stretchable. They start with standard components - a LED or chip - that they then link using meandering structures. These can then stretch by up to 40%. They have expanded the SiF platform to include this technology to produce inexpensive, thin, flexible, and stretchable foil incorporating electronics.

Fig. 3: As a result of the meander-shaped structures between the printed or ultrathin rigid electronic components, the foil incorporating electronics becomes stretchable.

The biggest enemy is the washing machine

Of course, if you want to make smart clothing mainstream, it needs to be able to withstand being washed. And that's where the biggest challenge lies at the moment.

By encapsulating it with silicone or polyurethane, we are trying to protect our foil-with-electronics during the wash. It's not the water or the detergent that's the problem, but the constant bending and pulling of the foil inside the washing machine drum. All this action creates tiny cracks in the foil, causing the electronic structures to stop working.

Our aim is to be able to wash the garment 25 times at +50°C. At the moment, electronic foil can only withstand 10 washes. This can be improved in the near future by creating a smart design and by choosing the right materials.

First prototypes

The goal is not to get this technology onto the catwalk in Paris or Milan, but to produce functional clothing that makes life safer and healthier. By that we mean clothes that improve our visibility in the dark, or that monitor a person's health and provide feedback.

A patient with a back injury can wear a T-shirt with sensors that measures his posture and then set off vibrations until he is standing or sitting correctly again. Or a cyclist can wear a time trial outfit that measures his heartbeat, speed, and streamlined posture on the bike and then sends feedback wirelessly to the earplugs he is wearing.

The fact that this is not just the stuff of dreams can be seen from the first prototypes produced by Holst Centre researchers. They have made a T-shirt featuring LEDs integrated into the front, back and sleeves, ideal for making cyclists more visible when they are out on the road in the evening, and an ECG sensor module.

Fig. 4: Prototype of a T-shirt with integrated ECG sensors.

Fig. 5: Using SiF technology, the sensor module can be incorporated wirelessly in the garment, while retaining the flexibility and stretchability of the fabric.

For more information, visit The Holst Centre.

About the Author

Jeroen van den Brand PhD is Program Manager at Holst Centre where he is leading the research team on integration and wearable technologies. He holds a PhD in materials science and technology from Delft University of Technology (2004).

Related Stories

Current And Future Developments In Printable, Flexible, And Stretchable Sensors