One of the most memorable movie lines of all time is one word: plastics. In 1967's The Graduate, a recent college graduate struggles to figure out his destiny and is told that the future is in plastics. If that movie were produced today, the line would have been "sensors."

Indeed, the future is in sensors. Smart sensors today are used just about every-where, including industrial, automotive, medical and agriculture. Sensors are used to monitor temperature, humidity, pressure, airflow, door contact, voltage, motion, smoke and more. In addition, there is a growing market for sensors to monitor our home environment and activities.

As the uses for sensors grow, so does the market. BCC Research (July 2014) estimates that the global market for sensors will grow at a compound annual growth rate of 10.1 percent over the next five years to nearly $155 billion.

As the applications for sensors increase, a growing number of products and capabilities are being introduced. These can be sorted into three categories: Industrial, Commercial, and Residential sensors. Each application has its own requirements.

Industrial Sensors

Sensors are used in industrial applications including factory automation, com-pressors, hydraulics and pneumatics, among others. These applications require sensors to be rugged yet sensitive and accurate.

For example, most industrial sensors are built with specifications that include:

- Temperature operation from -40 to +85 degrees.

- Resolution of 12 or 16 bit, enabling temperature accuracy down to .01 degree or less.

- IP67 rated, which specifies a high level of ingress protection against dust and water.

- Vibration, which specifies that a product can be in an environment that moves or shakes and will survive temporary or constant oscillation.

- 24 volt DC or AC power.

- Non-contact sensing, which doesn't require physical contact to monitor or measure. These sensors create an energy field to react to a change in that field. Examples include photoelectric, inductive and ultrasonic sensors.

- Intelligent protocols that govern both how the sensor conveys information and what information is conveyed.

- Rugged connectors that usually are airtight and watertight, typically with M12 locking, which allows connectors to be locked and tightened.

An industrial sensor on the assembly line.

Industrial sensors often must be calibrated to ensure accuracy. Industrial applications may require annual calibration or a third party to calibrate instruments to a known source.

Because industrial sensors are priced higher than other sensors—as much 100 times the cost of residential sensors—they are built to last longer and are warrantied appropriately. Industrial warranties can extend as long as 10 years.

Commercial Sensors

Commercial sensors are used as components in an array of products, including building control systems, soil analyzers, automotive switches and medical diagnostic equipment, to name a few. These applications require a high degree of sensitivity but often don't require the ruggedness of industrial sensors.

Commercial sensor specifications are similar to industrial, with a few exceptions:

- Temperature operation from -20 to +70 degrees.

- Resolution enabling temperature accuracy down to .10 degree or less.

- Ingress protection against dust, and if needed, against water.

- Battery or wall power.

- Sensing capabilities for temperature to monitor building energy consumption, lighting control using motion to perceive people being present, etc.

- More relaxed connectors, open contacts/screws, USB and micro USB, unless in applications where watertight connectors are required.

Automotive switches and sensors fall under the commercial heading.

Calibration of sensors is very important in commercial applications, and some are required by law to provide a calibration certificate. For example, a gasoline pump that measures the amount of gas and the level of the tank requires government certification for accuracy.

Because of these relaxed standards, commercial sensors tend to cost less than industrial sensors. The warranty period usually ranges from two to five years.

Residential Sensors

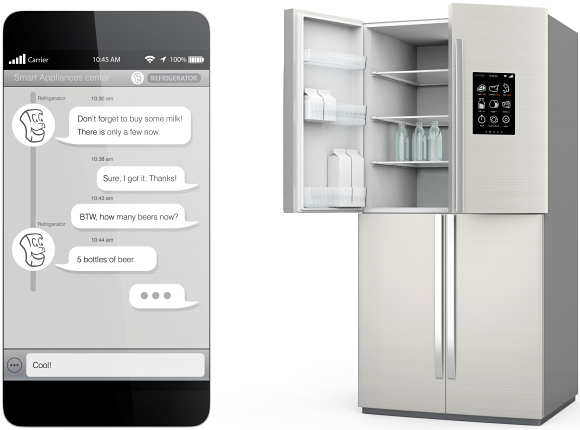

Residential sensors are used in a host of applications, from smart thermostats and appliances, to wireless monitoring for water and humidity. The most price conscious of the three applications of sensors, residential sensors have the least stringent specifications.

- Temperature operating range usually mirrors what's found in a home, with tem-perature accuracy within plus or minus one degree.

- Enclosures typically are standard plastic, and are not waterproof or IP rated.

- Battery power is standard.

- Connectors usually are USB or micro USB, unless an airtight and watertight connection is needed for kitchen use.

- Protocols are basic and often include an on-off protocol in which the sensor wakes at regular intervals to monitor and transmit information.

Residential sensors found in home appliances include the thermal and other devices in refrigerators, for example.

Despite relaxed specifications, certifications for residential sensors are strict. Residential devices often require Underwriters Laboratory (UL) certification and the CE mark in the European Union. Products might also need wireless certification from the Federal Communications Commission (FCC) and RoHS certification for Restriction of Hazardous Substances.

Residential sensors are priced competitively, ranging from $5 to $50 per sensor, depending on what the sensor is monitoring. The warranty for residential sensors reflects the lower price, and typically is less than a year.

Conclusion

While there are many choices when it comes to sensors, it's easy to narrow down your choices by looking first to the application. Two questions will help you decide which sensor is right: how mission critical is accuracy and what environment will it be used in?

About the Author

Mike Justice is a serial entrepreneur, industrial networking expert, and the founder and president of Grid Connect, a rapidly growing manufacturer and distributor of networking products and wireless sensors, with more than $12 million in worldwide sales.

Related Stories

LG Electronics Leads With Four Appliance Design 2015 Excellence In Design Awards

ROCKCHIP LAUNCHES WORLD'S LOWEST POWER WI-FI TECHNOLOGY

IPSO Alliance Announces Growing Support of Internet Protocol From IoT Leaders