The use of radio frequency identification (RFID) in sensing applications is growing, based on technology improvements and the need for low-cost wireless data transmission. In total, 2.31 billion RFID tags will be sold for all applications this year, up from 1.98 billion in 2009 according to market research firm IDTechEx. While most of the growth is due to an increase in the use of passive ultra-high frequency (UHF) tags, passive high-frequency (HF) RFID is growing and expanding into new applications, including wireless sensing.

As shown in Figure 1, HF RFID inductive coupling typically involves a 13.56 MHz tag, a reader, and a mobile/handheld computer. RF energy from the reader or interrogator activates the passive RFID tag and provides a command signal. The read range, data rate, and memory capability of the RFID tag/system are important criteria. In addition to the data rate's effect on the read range, other critical factors include the RF power level, antenna size, reader's receiving sensitivity, and communication protocol. The backscattering data signal from the tag is received by the reader and information is typically then sent to a computer for additional computations, notification, archiving, and other purposes.

Figure 1. The process of RFID data transmission and reception involves an RFID tag and reader with tuned antennas. The reader's data is typically transferred to a computer and, in some instances, the reader is powered by the computer's USB connection. Sensing adds another aspect to the system |

Powering a temperature-sensing element using a passive RF energy field that relies on inductively coupled energy from a 13.56 MHz reader is among the energy harvesting techniques that are also receiving a lot of visibility. To understand how this type of energy harvesting works, it is necessary to review the several different RFID technologies, based on their frequency range and their use of passive versus active RFID.

Passive RFID transponders transmit a signal only in response to the field emitted by the reader (or interrogator) when the reader is within a specific distance. A special passive category called battery-assisted passive (BAP) uses a battery for increased signal transmission range but still requires an external electromagnetic field source to wake up. Active RFID uses internal batteries to "wake up" and to transmit and extend its read range. Unlike active UHF RFID, adding a battery to an HF RFID tag does not extend the tag's read range but rather adds power to enable data logging. The effect of various parameters on different RFID frequency ranges is summarized in Figure 2, with the green symbols denoting good performance, blue symbols denoting a neutral rating for minor issues that may be addressed by appropriate design considerations, and red symbols denoting poor performance.

Figure 2. A comparison of four RFID frequency ranges shows the advantages and disadvantages of each technology (Source: Gene Fedors, RFID Technical Institute, The Evolution of RFID—Next Wave Principles, Challenges & Solutions.) |

The water/humidity tolerance characteristics of HF RFID make it a good choice for applications that involve high water-content items, such as ice, water, produce, meat, and beverages. A simple temperature sensor powered from the HF RFID energy enables the tag to transmit the condition of a temperature-controlled, or cold-chain, shipment to ensure that it has not passed a critical temperature. Continuous tracking is enabled by adding a battery to the tag to create a data logger. Matching the frequency to the application and the product to be measured is critical. A recent paper reviewing the performance of 2.4 GHz wireless temperature sensors monitoring bananas shipped from Costa Rica discovered that, while bananas are notoriously difficult to monitor due to heat generated from the ripening process, their water content presented the primary problem, resulting in the average loss of 50% of all data messages at 2.4 GHz and necessitating a switch to another radio platform.

The 2009 adoption of HF RFID for in-hospital applications has given new impetus to RFID designs for medical applications and, in particular, the addition of passive sensing for pharmaceuticals, particularly in cases where temperature tracking is essential, such as in clinical trials. The choice of HF RFID instead of UHF by the Health Industry Business Communication Council (HIBCC), the organization that developed the RFID standard, resulted from concerns over potential interference with sensitive hospital equipment. Additional HF RFID benefits include a secure proximity read that ensures 100% accuracy. This level cannot be achieved with active UHF. Because of the close proximity requirements of HF RFID, matching tags to medical equipment and devices does not require complex anticollision algorithms.

High-Frequency (13.56 MHz) RFID

RFID operation at 13.56 MHz requires compliance with ISO15693, ISO14443, ISO18000-3, or some other specification. The easiest way to obtain an ISO-compliant 13.56 MHz tag is with an IC designed specifically for the application. Additional or different sensing capabilities, such as humidity, pressure, shock, or light, can readily be added to a sensor design by using an IC that can work with any resistive sensor or has more than one input.

With these and other goals in mind, Melexis designed the MLX90129, a sensor transponder IC that includes a programmable interface for external resistive sensors. The 13.56 MHz sensor tag/data logger IC integrates analog functions for receiving and transmitting RF signals as well as digital functions for serial data interface to a microcontroller or external memory. The differential inputs can handle a range of resistive sensors. In addition, the IC has an internal temperature sensor and 3.5 Kbits of internal (EEPROM) user memory that can be extended with external memory through an SPI port. With this 13.56 MHz HF inlay, adding a 13.56 MHz-tuned antenna turns the IC into a RFID thermometer.

Figure 3 shows the connection of two resistive-bridge sensors to the input ports of the sensor transponder IC. An internal sensor signal conditioner amplifies, filters, and converts the output voltage of the resistive sensors. In addition, the two external sensors are supplied by a stable reference voltage from an integrated voltage regulator. If the differential capability of the IC is not used, the MLX90129 can be programmed to simultaneously use three sensors.

Figure 3. The MLX90129 sensor transponder IC easily connects to two external resistive sensors, external EEPROM memory, an antenna, and an optional battery |

In the standby mode, the IC consumes 14 µA max. at 105°C and in sleep mode, the maximum current draw is 15 µA. While the MLX90129 has been optimized for low-power, low-voltage battery-powered and batteryless applications, adding a coin-sized battery turns the passive sensor transponder into a standalone data logger.

Receiving HF RFID

The tag is only part of the HF RFID sensor IC system. One of the issues that users could come up against is that the RFID reader and sensing elements must both use a precise command set to communicate and decode sensor data with the transponder IC.

To provide a more complete system and simplify developers' design efforts, Melexis partnered with Proxima RF to develop a compatible HF RFID reader. An off-the-shelf Proxima RF USB Desktop Reader or AV-X mobile reader can read the data from MLX90129-based sensors. Communications between the reader and the tag use amplitude shift keying (ASK) modulation in accordance with ISO15693. Data rate per ISO15693 is 36 Kbps. The FCC/CE-certified USB Desktop Reader includes API, demonstration software, has an internal antenna, and receives power from the USB connection to a PC. The RFID reader is the source of RF energy for the RFID sensor tag. The read/write tag harvests energy from the HF RFID reader and supplies a regulated voltage to the other components in the embedded sensing node.

The receiving antenna influences the read range. Most desktop RFID readers have an internal antenna with limited power and thus a short read range. Mid-range readers coupled with an external antenna will provide a greater range, depending on the antenna size. With the 3 in. x 2.5 in. tag antenna, the desktop reader achieves a transmission range of 2.5 cm to 5 cm, depending on the antenna design. A mid-range reader should provide a range of 21.5 cm. The sensing range can be extended by using a tether, a 14–22 in. filament with a sensor at the end.

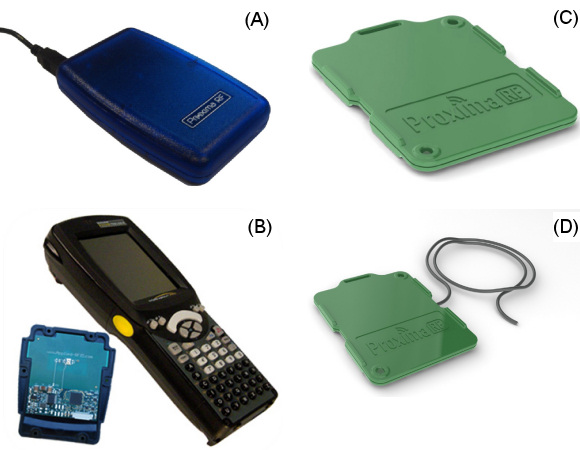

Designed specifically for Psion Teklogix Workabout Pro handheld computers, the Proxima RF AV-X mobile HF reader also operates with the other radios in the handheld device. This allows the operator to maintain WiFi connectivity, a bar-code scanner, or GPS functions while performing the HF RFID readings. As a result, mobile readings in HF-enabled sensor applications occur without disrupting an overall flow of data. The mobile computer allows a user to collect multiple data sets on mobile forms while also recording temperature. This is particularly useful when implementing food-safety protocols, such as saving time by using a commonly used handheld device to add regular temperature readings or add a temperature reading on receipt of goods. Figure 4 shows two HF RFID passive sensor reader options as well as a passive credit-card-sized temperature tag and a tag with a sensor extension.

Figure 4. The USB Desktop Reader (A), AVX Mobile Reader (B) and the soon to be available Mid-range reader (no image) offer options for interfacing to the MLX90129 transponder found in a temperature tag (C) as well as a tag with a sensor extension (D) |

The combination of sensing and HF RFID reading allows temperature monitoring of sensitive products such as foodstuffs, pharmaceuticals, or blood bags, from the source, during transit, and directly into the final destination—a restaurant or healthcare environment, for example—for complete end-to-end temperature tracking.

Single vs. Multiple Tags

HF sensing transmission requires one-on-one transmission between the tag and reader. As a result, when multiple tags are present, they are processed in sequence. Within the RF range of a single reader, anticollision sequences are used to inventory multiple tags simultaneously. However, this could result in a reduced read range on the sensor tags because of the increased power consumption.

While HF RFID performs well in water-rich and high-humidity situations, proximity to metal can degrade the HF RFID signal transmission. To avoid problems, one application tip is to either avoid metal or create a barrier using any nonmetallic material such as plastic, wood, or rubber between the tag and the metal.

The sensor transponder IC and reader are an easy-to-calibrate system. The reader can write a password-protected product ID directly to the sensor tag; these product IDs can be EPC and GS-1 compatible. When ID-secure proximity readings are required (rather than requiring that sensor readings remain secure), the Melexis IC chip and temperature-sensing elements can be combined with Atmel ISO14443-B passive encrypted RFID tags and read with the Proxima RF reader.

Development Tools

Figure 5. The DVK90129 RFID Sensor Kit includes a desktop reader, evaluation board, and software. The EVB90129 evaluation board is populated with a temperature, light sensor, and potentiometer |

The kit includes an evaluation board featuring the MLX90129, a plug-and-play and FCC-certified Proxima RF desktop reader, interface software, and API together with the related licenses. The software includes tools specifically for the 13.56 MHz HF RFID industry. Figure 5 shows the contents of the design kit.

The kit has preprogrammed settings for the sensors, 128 Kbits of external memory for an XML-based configuration file, and the tools to export data, allowing characterization of the sensors and fine tuning of the MLX90129 settings. Optional off-the-shelf credit-card-sized temperature-sensor or sensor extension tags allow immediate implementation of temperature sensing for many applications. The sensor tags have a demonstration application that provides accurate temperature information with the simple push of a button.

HF RFID Applications Made Easy

A typical application shows some of the design decisions that are involved in applying HF RFID sensing. For example, consider monitoring and data logging the temperatures experienced by a food product that must remain below a specific temperature to avoid spoilage. This is an ideal use of HF RFID data-logging sensing; common design considerations include the frequency of measurements, the amount of available monitoring time, and the data transfer rate to the reader.

The MLX90129's internal memory can store up to 216 data points. For most food products, temperature readings logged every half hour would be sufficient. If the tag records data points every half hour, it can store up to 108 hr. (4.5 days) of data. If the frequency of logging is increased to every 15 min., the tag's total recording time is reduced to 54 hr. (2.25 days). If more than 216 data points are required to either achieve increased measurement frequency and/or increased total monitoring time, the MLX90129's external memory option can be used, requiring a corresponding increase in available battery power.

Uploading data from the MLX90129's internal memory to the reader provides the fastest data transfer rate because the internal data points can be read in blocks—all 216 data points in internal memory can be read in 1–2 s using the mobile reader—as opposed to being read one at a time, as is the case with the external memory. In contrast, external memory can be used to log a larger amount of data, enabling measurements every 5 min. for a month's worth of data. The resulting 8928 data points would take almost 5 min. to upload using the mobile, desktop, or mid-range reader. Therefore, it is important to match the data-taking requirements to those for data upload.

In all cases, HF RFID sensor monitoring using a matched tag and reader simplifies the process, allowing the user to focus on the application requirements rather than the RFID aspects. With a few rather straightforward design considerations, an HF RFID passive sensing system can be readily configured. The development kit makes the whole process even easier for sensor developers with off-the-shelf temperature HF-RFID-enabled temperature sensors and data loggers that are now available on the market.

About the Author

Terry Rachwalski, VP Business Development, can be reached at Proxima RF Technology Corp., Vancouver, BC, Canada; 604-263-5529, [email protected].