Steven D. Roach, Hewlett-Packard, Electronic Measurements Division

|

Practical eddy current sensors vary in diameter from a few millimeters to a meter and have maximum sensing ranges roughly equal to the radius of the coil. Linearity is typically 1% of the sensing range and noise levels of 1 ppmrms/√Hz are common. Temperature drift ranges from ~100 ppm/°C to 1000 ppm/°C. A small sensor can resolve nanometer-size displacements and measure a 1 mm span to 10 microns total accuracy. Bandwidths of 50 kHz are readily achieved.

|

An eddy current displacement sensor consists of four components (see Figure 1): the sensor coil, the target, the sensor drive electronics, and a signal processing block, which can be a circuit or a microprocessor algorithm.

When the sensor coil is driven by an AC current, it generates an oscillating magnetic field that induces eddy currents in any nearby metallic object, designated the target. The eddy currents circulate in a direction opposite

|

The air-core transformer model is physically accurate, but for purposes

of circuit design, a lossy inductor is simpler and more useful. In Figure

2(B), the complex impedance of the sensor coil is represented a series LR

circuit. Both inductance, L, and resistance, R, change with target position,

or standoff. As the target approaches the coil, the inductance goes down

and the resistance usually goes up. The inductance changes by as much as

The inductance and resistance are important characteristics of the sensor because they correspond directly to physical mechanisms and can be used directly in circuit design and simulation. However, the quality factor, Q, is more directly connected to the ultimate performance of the sensor. Q is defined as:

|

|

(1) |

where:

ω = operating frequency of the sensor in radians per second

Q depends on the standoff, x, because both L and R are functions of displacement. The higher the value of Q, the more purely reactive the sensor. High Q leads to high accuracy and stability. The specific value of L is of secondary

|

Figure 3 shows how L, R, and Q depend on target standoff. The data come from real measurements on a 38 mm dia., air-core PC sensor with an aluminum target. The measurements were made on Hewlett-Packard's HP4285A LCR meter at 1 MHz. Note that the displacement has been normalized to the sensor radius (19 mm) so that the graph qualitatively depicts the behavior of sensors of all sizes. As standoff increases, the inductance increases by a factor of four, the resistance decreases slightly, and as a consequence the Q increases. The change in all three parameters is highly nonlinear and each curve tends to decay roughly exponentially as standoff increases. The rapid loss of sensitivity with distance strictly limits the range of an eddy current sensor to ~1/2 the coil diameter and constitutes the most important limitation of this type of sensing.

|

The coil's impedance is also affected by:

- Target size, flatness, and thickness

- Target material properties, especially conductivity and magnetic permeability

- Temperature of the target and the coil

- Coil geometry and DC resistance

- Operating frequency

Figure 4 shows the effect of target material for an aluminum and a stainless steel target. The steel target has 1/28 the conductivity of aluminum, resulting in higher eddy current losses and higher resistance, especially at close spacing. The target conductivity scarcely affects the inductance. Neither resistance nor inductance depends strongly on the target at large sensing distances where the coil interacts only weakly with the target.

Figure 5 shows the sensor's response to frequency. First note the resonant behavior at 7 MHz, which is caused by the cable and interwinding capacitance. The frequency where the inductance peaks is called the self-resonant frequency (SRF), and the sensor must be operated below it to look like an

|

Temperature drift proves to be the critical source of error in eddy current sensors and arises from a complex set of factors. Both the inductance and resistance have positive temperature coefficients that are dependent on frequency. For the 38 mm PC coil operating at 1 MHz, for example, inductance increases at 88 ppm/°C. and resistance increases at 2400 ppm/°C. (Temperature drift will be examined in detail in a later article.)

Target SelectionThe response of an eddy current sensor depends on both the conductivity and the magnetic permeability of the target. In some applications the designer is free to choose the target material; in others, the target is part of a machine or assembly over which the designer has no control. High-conductivity, nonmagnetic metals such as aluminum or copper make the best targets. Magnetic metals are also good choices, even though the sensor response is a mixture of eddy current and magnetic reluctance. Magnetic reluctance describes the way in which magnetic material modifies the effective permeability in a magnetic circuit. As a magnetic target approaches the coil, eddy currents reduce the inductance, while reluctance increases the inductance. Since these effects are in opposite directions, they may cancel each other. The net result is an easily avoidable null point in the sensor response at small standoff values.

The skin effect, or tendency for AC current to flow in the surface of a conductor, applies to both the coil and the target. Due to the skin effect, the current density in the target drops exponentially with distance from the surface. Skin effect is characterized by the skin depth, the distance at which the current density drops to 1/e of its surface value. The expression for skin depth in a conductor is given by:

|

|

(2) |

where:

δ = skin depth (meters)

ω = radian frequency (radians/second)

μ = magnetic permeability (henries/meter)

σ = conductivity (siemans/meter)

For nonmagnetic materials, µ = µo = 1.26 x 10-6 H/m. Table 1 shows skin depths in several materials for frequencies of interest in sensor design. Notice that the lower the conductivity and frequency, the more deeply the eddy currents penetrate the target. If the target is at least two skin depths thick, thickness is essentially eliminated as a factor in the measurement [2]. This rule-of-thumb, however, is extremely conservative.

| TABLE 1 |

|

Skin Depth ( |

||||||

|

Metal |

Conductivity (x 106 S/m) |

Conductivity relative to Cu |

Skin depth (µm) |

|||

|

10 kHz |

100 kHz |

1 MHz |

10 MHz |

|||

| Copper |

58 |

1.000 |

660 |

210 |

66 |

21 |

| Aluminum |

38 |

0.655 |

820 |

260 |

82 |

26 |

| 304 SS |

1.3 |

0.022 |

4400 |

1400 |

440 |

140 |

| Titanium Alloy |

0.59 |

0.010 |

6600 |

2100 |

660 |

210 |

Several target characteristics other than thickness, conductivity, and permeability affect sensor behavior in ways that are difficult to predict analytically. Differences are seen if the lateral dimensions of the target are less than twice the sensor diameter, the target is curved, or its surface roughness is comparable to the skin depth. Though these situations are difficult to model, all can be accommodated with measurements by building a prototype sensor and measuring its response with an LCR meter. A versatile multifrequency instrument such as the HP4285A is extremely valuable for sensor design because it displays L, R, and Q directly with enough sensitivity to measure even minute effects such as temperature drift.

Sensor DesignThe design of a nearly optimal eddy current sensor is surprisingly easy. We first need to establish some intuitive guidelines and a set of simplified design equations. Measurements of the prototype sensor with an LCR meter then provide highly accurate and detailed data for the design of the electronics.

If small size is the primary goal, sensors based on wirewound coils are the best choice. The fine magnet wire used in wirewound coils increases the sensor Q by maximizing the number of turns while minimizing the resistance. The magnet wire must be packed in perfect layers (usually by hand) under a microscope. The coils are then inserted in a machined protective holder and potted with epoxy to mechanically stabilize the windings. A wirewound sensor is a labor intensive product, and typically costs more than $100.

When cost is the primary consideration, coils printed on a PCB deliver excellent performance for a fraction of the cost of a wire wound sensor. The advantages of printing the sensor coil include:

- Prototyping. Tooling costs are only a few hundred dollars. A single prototype run can produce a large number of variations on the sensor design.

- Manufacturing. PCB processes are highly automated, standardized, and widely available. PC board processing scales well from tens to millions of sensors.

- Cost. Coils cost less than $1.00 in volume, but the cabling and connectors can easily dominate the overall price.

- Performance. The performance competes with wirewound sensors for larger diameters (>10 mm).

- Special configurations. Arrays of sensors and sensors on flex circuit material create unique application opportunities.

The primary tradeoff with printed sensors is size. It is difficult to print a coil <10 mm dia. on a PCB and still match the performance of a wirewound sensor. Table 2 outlines the most important factors and tradeoffs in the design of an eddy current sensor.

| TABLE 2 |

|

Factors in Sensor Design [2]

|

|||

| Factor |

Why |

How |

Tradeoffs |

|

High-quality factor, or Q

|

Fundamental determinant of temperature stability, power consumption, noise; do anything possible to increase Q

|

Increase frequency and inductance, decrease resistance; use a wire-wound coil for small sensors

|

Difficult to achieve high Q with small sensors

|

|

High inductance

|

Increases Q and reduces power

|

Use more turns in the coil, a larger diameter sensor, or a ferrite core

|

High inductance is often accompanied by low self-resonant frequency

|

|

Low resistance

|

Increases Q and reduces power

|

Use more conductive coil windings, larger wire or thicker traces, keep temperatures low

|

Frequency trades off with the need for high inductance

|

|

Optimal coil size

|

Maximizes sensitivity to displacement

|

For highest accuracy and stability choose radius=3 x range; a small sensor has small range, too large a sensor has reduced sensitivity

|

The larger the sensor the larger the "spot size" or area of the target measured by the sensor; the larger the sensor, the larger the required target dimensions

|

|

Flat, disc-shaped coil configuration

|

Maximizes sensitivity by placing all of the turns close to the target

|

Use a printed coil

|

Flat coil limits the number of turns, reducing inductance

|

|

Operate at high frequency

|

Increases Q and redeuces power in the sensor; increases sensing bandwidth

|

Reduce interwinding and cable capacitance

|

Must stay below the self-resonant frequency; high frequency usually increases power in the electronics

|

|

Minimize cable length

|

Reduces cable noise, temperature drift, and cost of cabling; increases the self-resonant frequency; allows use of lower quality, cheaper cabling

|

Place the critical circuits in a pod close to the sensor or load electronics on back of printed coil

|

Placing electronics on or near the sensor limits the temperature range

|

A complete sensor typically has a cable joining the coil and the electronics. The cable can be coaxial, twisted pair, ribbon, or traces on a PCB. The cable affects system design and performance in several ways because all cables have inductance, capacitance, and DC resistance. The inductance of the cable adds to that of the sensor. Because the cable inductance is static (not sensitive to displacement), it reduces the sensor's net sensitivity. The cable capacitance forms part of the resonant circuit network, so any instability in the cable capacitance degrades measurement accuracy. Changes in cable capacitance with temperature and cable movement produce measurement errors. A common problem with eddy current sensors is noise traceable to cable vibration. Eddy current sensors can be so sensitive that a hand moving near a twisted-pair shows up as an observable displacement error, so the highest performance sensors require fully shielded coaxial cable. The resistance of the cable is in series with the sensor coil and contributes to a reduction in Q and to temperature drift. For the best performance, we must use high-quality microwave coaxial cable such as RG-178 or RG-316. These cables have a highly stable Teflon dielectric and low capacitance.

When price is an important consideration, and some stability can be sacrificed, twisted-pair or ribbon cabling is adequate and can be used with very inexpensive connectors. Twisted-pair can be soldered to a printed coil sensor directly, eliminating at least one set of connectors. Measurement errors due to cabling can be greatly reduced by placing the sensor interface circuitry on the back of a printed circuit coil. Even though the circuit operates in the coil's magnetic field and the coil "sees" the circuitry, performance is not seriously affected. It is important, though, to avoid a ground plane or any large loop areas in the circuit because the sensor would see these as a second target. With the sensor circuitry integrated with the coil, we still must deliver power and retrieve the output signal through cabling, but this cable in no way affects the accuracy of the measurement.

To establish guidelines for the design of the sensor we need a preview of the sensor drive circuitry. The circuits developed in the "Circuit Design" section of this article place the sensor in an oscillator loop where it is resonated with a capacitor. The frequency of oscillation (resonant frequency) is dependent on target displacement and is the output of the circuit. In an LC oscillator the frequency is proportional to 1/√LC. The design of an air core sensor with a printed circuit coil follows these steps:

1. Set the outer coil radius, ro. We need:

ro > 2 x sensing range for a typical design

ro = sensing range for an aggressive design

2. Choose a manufacturing technology for the coil. The manufacturing technology determines the width, w, thickness, t, and pitch, p, of the traces that make up the coil windings.

3. Calculate the number of turns that can be packed on a single layer.

The outer coil radius, ro, was determined in an earlier step.

The inner coil radius, ri, should be at least 1/3 the outer radius.

The number of turns per layer is:

|

|

(3) |

4. Calculate the unloaded inductance using Burkett's inductance equation [3]. The unloaded inductance is the inductance of the free coil with no target. Assume one layer for now.

|

|

(4) |

5. Calculate the cable capacitance, CCABLE, from the cable length and the manufacturer's specification of capacitance per unit length. Assume that the interwinding capacitance, CIWC, is zero for a single layer coil. For a two-layer coil, estimate CIWC to be ¼ the parallel plate capacitance, calculated as if the windings were solid sheets of metal. Thus, for a two-layer coil:

|

|

(5) |

where:

εr = relative dielectric constant (a dimensionless number; εr = 4.2 for FR-4 PC board)

εo = permittivity of free space = 8.86 × 10-12 F/m

h = thickness of coil (meters)

6. Estimate the self-resonant frequency:

|

|

(6) |

7. Choose the operating frequency. For the LC oscillator circuit, the minimum frequency coincides with the maximum inductance and occurs at maximum standoff. The maximum inductance is given approximately by Equation 4. We want the maximum frequency, which is typically about twice the minimum, to be no more than 1/3 the SRF so that the cable and interwinding-capacitance have only a small effect. With these considerations we have:

|

|

(7) |

|

|

(8) |

|

|

(9) |

where:

C = total parallel resonant capacitance and L comes from Equation 4. Equation 9 can be used to calculate the capacitance required to resonate the sensor at the desired frequency.

8. Calculate the DC resistance of the coil:

|

|

(10) |

where:

l = length of the coil windings

ρ = 1/σ = resistivity of the coil windings

w = width of traces of coil windings

t = thickness of traces in coil windings

9. Estimate the worst-case AC resistance, which is higher than the DC resistance because of the skin effect and proximity effect.

| RAC = 2RDC | (11) |

10. Calculate the unloaded Q. (The Q of the free coil with no target.)

|

|

(12) |

We need:

Unloaded Q > 15 for a typical design

Unloaded Q > 5 for a design with a Q >15

If Q is not high enough, consider adding additional layers to the coil. Doubling the number of layers doubles the number of turns, which quadruples the inductance while only doubling the resistance. The Q therefore roughly doubles. Also, follow the guidelines in Table 2 to increase Q.

11. Is the unloaded inductance acceptable? If the inductance is too high (a rare situation except for large coils), the resonant capacitance may be too low, allowing cable and interwinding capacitance to dominate the sensor behavior. If the inductance is too low (a common problem, especially for small coils), the circuits may burn excessive power or require an impractically high operating frequency for acceptable Q.

We need:

1 µH < L < 100 µH for a typical design (but aim for L > 10 µH)

L < 1 µH for an aggressive design

If the inductance is too low, increase the number of turns by using a finer pitch PC technology, adding layers, or using hybrid integrated circuit technology.

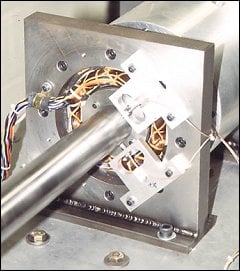

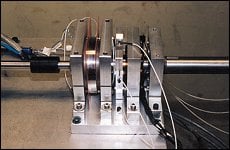

12. Build a prototype of the coil and measure it on an LCR meter to confirm the design and to collect data on L(x) and R(x) (x = standoff). The data will be used to design the electronics. To make these measurements, attach the target and sensor to a micrometer with an appropriate fixture.

Circuit Design

|

The basis for nearly all eddy current sensor circuits is shown in Figure 6, where the sensor coil is resonated with a capacitor. Resonance causes abrupt changes in the circuit impedance Z(jω), as shown in Figure 7, in which the middle point is x = 4 mm. In Figure 7(A), the magnitude peaks at the resonant frequency and the height of the peak depends on the Q, which in turn depends on the target displacement. In Figure 7(B), the phase shifts from +90 at low frequency to 90 at high frequency.

|

A common way to convert the displacement to voltage is simply to drive the resonant circuit with a current source at a fixed frequency and demodulate either the amplitude or the phase of the voltage that appears across the sensor. Both amplitude and phase detection are complex, requiring an independent oscillator, phase detector, low-pass filter, and analog postconditioning circuits.

With the goal of designing a position sensor of the lowest possible cost, consider the self-oscillating circuit of Figure 8. It is a straightforward gate oscillator using low-voltage CMOS logic gates. The two inverters produce

|

- The output can be connected directly to the counter-timer port of the microcontroller and digitized simply by counting pulses. The microcontroller digitally linearizes, offsets, and scales the output using constants stored during calibration.

- Because every sensor component (the coil and all electronics) is under calibration, no costly, high precision devices are needed.

- The circuit operates on a single supply voltage at a few hundred microamps of current.

- The circuit requires 7 electronic components at a material cost of about $0.35. A PCB coil is on the order of $0.50 in volume. With the addition of the load and test costs, the cable and assembly labor, the entire sensor subsystem adds as little as $2.00 to the cost of a high-volume, microcontroller-based product.

The circuit in Figure 8 oscillates at the resonant frequency given by:

|

|

(13) |

To find the component values for Figure 8 we first determine the desired operating frequency from the procedure described earlier. Then we solve Equation 13 for Cp and choose the nearest standard value. Rs determines the amplitude of the signal at the input of the first inverter as well as the power consumption. To minimize noise it is desirable to have the largest signal possible at the inverter input. The smaller the value of Rs, the larger the signal, but the greater the power consumption. At resonance, the impedance of the of the LC tank is purely resistive and is equal to:

|

|

(14) |

Rs and Rres form a voltage divider, so the amplitude is given by:

|

|

(15) |

where:

4/π VDD is the amplitude of the fundamental of the square-wave output signal. We need only consider the fundamental component because Rs and the LC tank form a bandpass filter centered on the frequency of oscillation. This filter attenuates all but the fundamental component to a negligible level. A good rule of thumb is that the peak-to-peak amplitude in Equation 15 should be at least half the supply voltage, VDD, when the coil is unloaded (i.e., when the target is not present). With this guideline we would set Rs ≈ Rres, with Rres found for the unloaded case.

The higher the resistance at resonance (Equation 14), the less power it takes to drive the sensor. Notice that the resistance goes up and the power goes down for higher frequencies, higher inductances, and higher values of Q.

CMOS gate oscillators such as that in Figure 8 exhibit curious power dissipation characteristics. The first inverter operates part of the time with its input at the logic threshold. This places it in the so-called linear region, where it acts like a class B linear amplifier and conducts current directly from the power supply to ground. The higher the supply voltage, the higher the class B current, so the power in the circuit of Figure 8 increases rapidly with supply voltage. For example, going from VDD = 2.0 V to 2.5 V increases the current by a factor of four. By placing a resistor between VDD and the inverter power pin the circuit can be operated on higher supply voltages while maintaining low power consumption. The resistor drops the voltage on the inverters and provides negative feedback to limit the class B current. Of course, the decoupling capacitor should still be attached to the power supply pin of the chip.

A Model Sensor System Design

|

|

Figure 10 shows the frequency output for the model sensor system. The data were taken with the aid of an HP53132A frequency counter. Since the total inductance shift in Figure 3 is 4:1, the frequency shift is the square root of that or 2:1. Operating between 1 MHz and 2 MHz, there is an impressive total frequency shift of almost 1 MHz.

The frequency is a highly nonlinear function of displacement, so linearization is essential. The empirically derived function:

|

|

(16) |

|

with fo = 981 kHz produces the linearized output of Figure 11. The linearity error is <1% of the 20 mm F.S. range, or 200 µm. Even better linearity could be attained by calibrating at a large number of points and using piecewise correction. The advantage of linearizing with Equation 16 over piecewise linear correction is that the constants, m, b, and fo, can be obtained with only three calibration points: the end points and a point near the middle of the range. It is not even necessary to know the midrange point exactly since the calibration procedure need only place this point on a straight line between the end points.

|

Figure 12 shows the sensor amplitude and power supply current. Notice that the amplitude decreases for small values of standoff because the Q is dropping rapidly. The reduced Q also requires more drive current from the power supply. With a supply voltage of 2.0 V the worst case power dissipation is <600 µW. The power is so low that the capacitance of a 15 pF scope probe on the output increases the power by 20% due to charge pumping.

The frequency output of the sensor is highly nonlinear, changing some 125:1 in slope over the full. If the circuit noise and quantization error are roughly constant in terms of frequency, then they will not be constant in terms of displacement. In terms of displacement, both the noise and resolution vary in inverse proportion to the slope of the frequency curve, so they will vary by 125:1 also. If we measure frequency by counting N pulses over a gate time of Tg, the estimated frequency is fest = N/Tg. The quantization error is ±1 count, so the frequency resolution is Δf = 1/Tg. Clearly, the longer the gate time (and the slower the sample rate), the higher the resolution. Arbitrarily high resolutions can be reached by counting for longer periods. Noise is reduced at the same time because the counting process acts as a digital low-pass filter.

The resolution in terms of displacement depends on the slope of the frequency curve:

|

|

(17) |

|

Noise follows the same form as Equation 17, increasing for larger values of standoff. Figure 13 shows the resolution and noise of the model sensor for a gate time of 100 ms, or a digitizing rate of 10 sps.. The noise is ~20 Hz p-p as measured with the HP53132A counter with a 100 ms gate time. Most of the noise is at very low frequency (<1 Hz) and can be caused by vibration or temperature changes due to air currents. Notice that higher resolution and lower noise can be attained by simply limiting the maximum standoff.

A very good way to observe the noise is to display the output square wave on a digital oscilloscope and delay the scope by 1 ms. With the sensor operating at 1 MHz (a 1 µs period), the scope displays the phase noise accumulated over 1000 cycles. With the digital scope set to infinite persistence, the

|

Figure 14 shows the temperature stability of the sensor and the electronics. The stability is poorer at large displacements because at large values of standoff the temperature stability suffers the same disadvantage as the resolution and noise. Limiting the sensing range can greatly improve temperature stability. Table 3 summarizes the measured performance of the model sensor for two values of full-scale range.

| TABLE 3 |

|

Summary of Performance of the Model Sensor System

|

|||

| Performance Parameter |

10 mm Range |

20 mm Range |

Units |

|

Frequency range Max. Min. |

1.88 1.05 |

1.88 1.00 |

MHz MHz |

|

Linearity |

1% |

1% |

of range |

|

Quantization error 1 sps 10 sps 100 sps |

17 14 11 |

15 12 9 |

bits |

|

Noise, peak-to-peak 1 sps 10 sps 100 sps |

14 13 12 |

12 11 10 |

bits |

|

Temperature drift Electronics Sensor |

-150 +300 |

-540 +1200 |

ppm of range/°C |

|

Power supply VDD IDD Power Power supply rejection |

2.0 280 560 7 |

2.0 280 560 18 |

V µA µW %/V |

Conclusion

Eddy current sensors are advantageous for precision, noncontact displacement

sensing where the range is relatively small. They are especially useful

where the environment is dirty or sensing through intervening materials

is required. In applications where a microcontroller is available, a high-performance

eddy current sensor can be added to the system for a few dollars, using

printed circuit sensors and manufacturing methods common to all electronic

products.

Experience is essential to the successful design of eddy current sensors, but it is quickly gained because printed circuit sensors are easily and cheaply prototyped and only basic electronic instruments are needed for testing. The essential design calculations can be done with a desktop computer and a spreadsheet program. Future articles will investigate advanced computer-aided design methods for optimizing the sensor and advanced circuit designs for improved temperature stability.

References1. Scott D. Welsby and Tim Hitz. Nov. 1997. "True Position Measurement with Eddy CUrrent Technology," Sensors, Vol. 14, No. 11:30-40.

2. J.H. Smith and C.V. Dodd. 1-5 Oct 1973. "Optimization of eddy-current measurements of coil-to-conductor spacing," Proc Annual Fall Conference of the American Society for Nondestructive Testing, Chicago, IL:1-15.

3. Frank S. Burkett, Jr. 12-12 May 1971. "Improved designs for thin film inductors," Proc 21st Electronic Components Conference, Washington, DC:184-194.

|

The ROMAC Research Facility Lloyd Barrett, the University of Virginia

The magnetic bearing research program, housed in the ROMAC laboratories, is one of the largest in the world. Experimental platforms include 12 magnetic bearing rigs ranging from a tiny artificial heart pump up to a 200 HP centrifugal compressor. The program's research covers the full spectrum of the technology, from hardware issues (system dynamics, magnetics, amplifiers, sensing, and controllers) to the the development of control methods.

Lloyd E. Barrett is Professor and Laboratory Director, ROMAC Laboratories, Dept. of Mechanical, Aerospace, and Nuclear Engineering, the University of Virginia, Thornton Hall, McCormic Rd., Charlottsville, VA 22903-2442; 804-924-3292, fax 804-982-2037. |