Here's the scene: U.S. Customs inspectors want to verify that a cargo of kegs coming into this country really do contain roofing tar. So what the inspectors do is haul a few of the kegs up to a second story and drop them to the ground. If it's tar, it's a mess. If it's sarin, well, it's a bigger mess. Another tack is to open the container of interest and pull a sample for lab analysis. Is this cool? No, it is not.

Here's the scene: U.S. Customs inspectors want to verify that a cargo of kegs coming into this country really do contain roofing tar. So what the inspectors do is haul a few of the kegs up to a second story and drop them to the ground. If it's tar, it's a mess. If it's sarin, well, it's a bigger mess. Another tack is to open the container of interest and pull a sample for lab analysis. Is this cool? No, it is not.

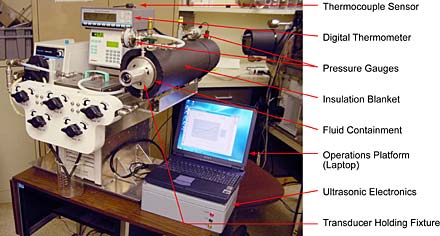

What is cool is an acoustic inspection device (AID) developed at Pacific Northwest National Lab (PNNL). A cousin of the more familiar acoustic-based flaw detector, AID operates on two acoustic parameters, velocity and attenuation as a function of temperature and frequency, to noninvasively identify the contents of sealed containers holding either liquids or bulk solids. Let's watch it in operation.

The Customs agent eyeballs the container to be inspected and chooses one of two interchangeable transducers, a 1 MHz for smaller containers (say, a 2 liter bottle) or a 200 kHz version for tanker cars. The agent then presses the 4 lb. battery-operated AID against the side of the tank. A gel-filled coupling fits over the transducer's nozzle to ensure an airtight contact with the container. When the trigger is squeezed, the transducer sends an ultrasonic pulse into the tank and measures the travel time and strength of the returning echoes. Here's where it gets really clever.

It turns out that every substance has its own echo velocity and attenuation signature (e.g., diet vs. regular Coke). PNNL developed an algorithm that uses digitized waveforms of the ultrasonic return signal, temperature readings, and path length to calculate temperature-corrected ultrasonic velocity and relative attenuation coefficient values of nearly every chemical composition. Enter the Velocity Attenuation Measurement System (VAMS), which can compile a completed dataset for a liquid in <6 hr. Researchers can use VAMS to develop customized databases for individual clients, populate the databases rapidly, and distribute them via the Internet.

When the user compares the signature of the vessel's contents to a library of material characteristics in the AID's onboard database, a reading appears on the device's Compaq H3760 Pocket PC screen in <5 s. An onboard thermistor measures ambient temperature to compensate for thermal variations from one climate to another.

AID can also detect a floating object, hidden compartment, or other anomaly by comparing the actual pulse echo time to what the container's diameter says it should be. Lack of a return signal can indicate the vessel's fill level. The alternative is to open the container and poke around with a stick to find out if someone accidentally dropped a crate of guns into the diesel fuel.

PNNL developed the first AID units for weapons inspection in Iraq following the Gulf War. It received subsequent support from the Department of State, IRS, DoE, and the U.S. Customs Service. The latest model is licensed to MGB Ltd., which is manufacturing and marketing it worldwide as the Product Acoustic Signature System. It is now being field-tested by U.S. Customs.