In sawmills, optimization is an in-process procedure that maximizes the quality and quantity of high-value board sizes from a limited and environmentally valuable supply of random-shaped logs. In the optimization process, 3D profiles of each raw board are analyzed to position saws to best edge the individual boards to width and then trim them to length, removing defective areas and increasing quality and productivity at the end of the line. Properly implemented optimization can improve yields by 15% or more. A larger sawmill that cuts an average of 80,000 board feet per shift with two shifts produces 40 million board feet (MMBF) per year. Improving the yield by an additional 15% results in 6 MMBF per year at $225 per MBF for a return of $1,350,000 per year.

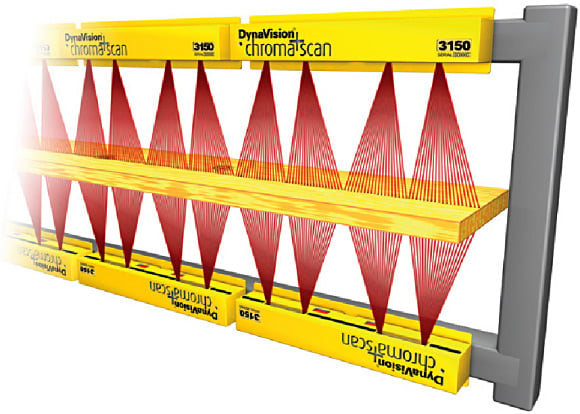

In board production, optimization has traditionally involved mounting banks of 3D laser sensors above and below the board conveyor lines to provide high-density 3D geometric profiles of each rough board as it passes the inspection station (Figure 1). The differential configuration, with sensors above and below the conveyor line, provides true board profiles even if boards are not sitting flat on the conveyor. Typical inspection rates are up to 120 boards per minute with some systems running as high as 200 boards per minute. Depending on the length of the boards, 20 or more sensors may be used to provide full surface coverage.

Figure 1. Typical board inspection system |

Over the past three decades, 3D sensing has evolved significantly, with profile resolution improving from 3 in. spacing between data points to 0.3 in. spacing, and frame rates have increased to 2 kHz. These improvements provide much higher-density data input to the process, allowing the operators to detect smaller defects and to make better decisions on optimal cutting paths.

Adding 2D Inspection

The next step to further improve yield is to implement automated detection of surface defects such as knots, splits, and stains on the boards by using 2D full-color surface inspection. Implemented early in the process, the 2D information is analyzed to automatically cut out surface defect areas from the boards, eliminating the cost and time required to process defective board sections, only to discard them at the sorting station at the end of the process stream.

Adding a separate 2D surface color inspection station to the line presents an integration challenge, requiring the mounting of separate 2D and 3D sensors, cabling all components, transporting and tracking work pieces through the two inspection areas, and synchronizing data from all sensors to match the 2D and 3D data to the same zone on each board to insure proper decision-making on each piece. The resulting complex system would consist of many separate elements, with the end user faced with high system-acquisition cost, increased floor-space requirements, and the need to support and maintain all of the components and their interconnections.

To dramatically simplify the integrator's challenge in these types of applications, LMI Technologies has introduced a family of sensors which combine 3D high-density profile scanning with true color 2D imaging for automated visual inspection for surface defects into the same sensor package. Built into each sensor are laser projectors for 3D profiling and high power LEDs and imagers for surface imaging. With a frame rate of 2 kHz or higher, these sensors provide very high-speed inspection capability. One such sensor, an LMI chroma+scan 3300 3D profile and color sensor is shown in Figure 2. The chroma+scan 3300 sensors feature a 20 in. standoff distance, an 8 in. measuring distance, and are housed in a gasketed, IP67-rated aluminum housing.

Figure 2. chroma+scan 3300 3D profile and color sensor |

Integrating 2D and 3D inspection capability in a single sensor package is only the first step in simplifying the integrator's tasks. "Smart Sensor" technology further reduces the work involved because the sensors provided to the integrator have internal processing that applies the optical calculation equations and factory-developed linearization factors, provides automatic gain control to ensure accurate readings independent of the object's surface texture and color, and converts measured values to engineering units—.

In many sawmill and other applications, obtaining high-resolution data requires the use of multiple sensors, each inspecting a separate zone of the work piece. In a system built from discrete and separate sensors, this requires that data be synchronized and that multisensor data streams are stitched into a single data file. To simplify the system integrator's tasks of synchronization and management of the combined data, LMI has developed a synchronization platform known as FireSync that is designed to accept and integrate data from multiple vision sensors, as well as other local inputs, such as encoders and photocells that are monitoring the parts conveyor. The FireSync platform is a synchronized, scalable, distributed vision processing architecture for building reliable, high-performance systems. It combines 3D and color images from multiple scanners and an encoder into a single image file, ensuring that the vision and dimensional information are precisely matched and scaled to the board's surface.

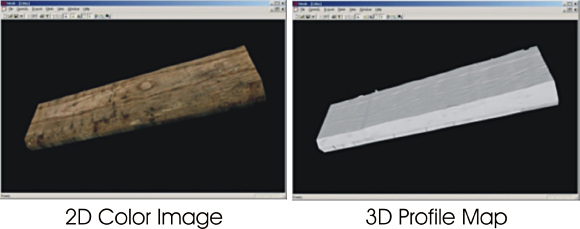

Combining 3D measurement and 2D color data also allows for internal parallax correction of errors to the 2D map that can be caused by variation in thickness of the work pieces or by their movement toward the sensors. This ensures that the 3D profile and the 2D color map match, no matter how the work piece is positioned. Figure 3 shows the 2D color and 3D profile data outputs from the sensor.

Figure 3. 2D and 3D outputs |

Connecting high-speed sensors to a host system processor can still present some challenges. Even with smart sensors that convert optical information to engineering measurements, it is common for sensors to output hundreds or thousands of frames per second, with each frame containing hundreds to thousands of data points. Frequently the sensors must be located remotely from the system processor, requiring the ability to reliably transmit masses of data over long cable lengths. Using a standard industrial communication protocol simplifies the integrator's job and reduces both the cost and risks of implementation. Although a number of standards are available, such as USB 2.0, FireWire, and Camera Link (developed specifically for industrial and scientific imaging), and although each has useful features, Gigabit Ethernet (GigE) is broadly accepted, easy to apply, and uses inexpensive cabling running up to 100 meters without repeaters. Data are sent from the FireSync platform over a single GigE output cable to the host computer, reducing wiring costs and improving reliability.

A typical example of chroma+scan 3300 sensors carrying out combined 2D and 3D inspection of boards is shown in Figure 4. In this case ten sensors are used, five above and five below the conveyor for full surface inspection.

Figure 4. chroma+scan 3300 sensors inspecting boards (Photo courtesy of Comact Equipment Inc., Saint-Georges, QC, Canada) |

Conclusion

Sensors with combined 2D and 3D sensing simplify the task of integrating complex multifunction inspection systems. Risk and development costs for the integrator are minimized with internal data processing in the sensor; multiple sensor synchronization and data stitching provided by the FireSync platform; and standard GigE communications. Combined-function sensors minimize complexity, mounting, and cabling tasks, and reduce overall system cost. When the system is installed, the end user benefits from system simplicity, with reduced maintenance costs and ease of operation.

About the Author

Dr. Walter Pastorius is Technical Marketing Adviser for LMI Technologies Inc., Delta, BC, Canada. He can be reached at 519-945-6373, [email protected].