Sypris Test & Measurement, Inc., manufactures high-precision, high-resolution gaussmeters. Magnet and magnetized manufacturers and shippers can use these devices to test packages for compliance with FAA and International Civil Automation Organization (ICAO) requirements for shipping these materials by air. First we'll discuss the regulations involved, and then we'll explain the setup and equipment required to achieve compliance.

|

Shipping Regulations

The FAA adheres to the U.S. Department of Transportation's (DoT) Office of Hazardous Materials Safety's "Code of Federal Regulations." As stated in CFR49, section 173.21, it is forbidden to offer for transportation or to transport any package with a magnetic field of >0.00525 gauss (G) measured at 15 ft. from any point on the surface of the package. The FAA imposes strict penalties for violations. Even stricter standards were adopted in 2004, requiring packages to carry a special sticker certifying the package as air eligible.

Most passenger and cargo airlines, however, adhere to the more stringent International Air Traffic Association (IATA) regulations. The IATA Dangerous Goods Regulations is a "field manual" version of the ICAO's technical instructions. As of 2003, the IATA's classification and definition of "magnetized material" was "any material which, when packed for air transport, has a magnetic field strength of 0.002 G or more at a distance of 7 ft. from any point on the surface of the package."

|

The packages must be checked for total magnetic field emission: If the field exceeds 0.002 G at 7 ft. from any point on the surface of the package, then packaging instruction 902 in the IATA dangerous goods regulation must be followed. If the total field emission exceeds 0.00525 G at 15 ft. from any point on the surface of the package, the package cannot be accepted for air shipment. If the 0.00525 G requirement is met, you can ship the package by air on an international flight provided you fill in the dangerous goods declaration form and label the package appropriately. The package must have the label for handling of Class 9 magnetized materials.

Important: The above is for information purposes only and does not fully state the regulations. Be aware that you cannot rely on the general summary above to make decisions; rather, you should know that these regulations exist and that you must refer to them.

Measuring Magnetic Fields

The 3-channel 7030 bench-top gaussmeter with the ZOA73-3208-05 3-axis probe (see Figure 1) allows fast, accurate 3-axis vector sum measurement of packages containing magnets and magnetized materials.

Figure 1. Sypris's 7030 gaussmeter with a 3-axis probe provides resolution down to 0.1 mG. The system is also capable of displaying the vector sum value, thus eliminating the uncertainty of single-axis measurements. |

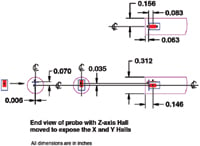

The probe contains three orthogonal Hall effect devices in its tip (see Figure 2). The gaussmeter automatically corrects each Hall effect device for nonlinearity and displays the individual X, Y, and Z components of the magnetic field as well as their vector sum.

Figure 2. This diagram shows the ZOA73-3208-05 3-axis probe Hall effect sensor locations. The close proximity of the Hall effect devices ensures accurate and reliable vector sum magnetic field measurements. |

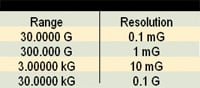

The gaussmeter and probe system's ranges and resolutions are shown in Figure 3. In all cases, resolution for each range is 1 part in 300,000. The meter also offers selectable units of tesla (T), oersted (Oe), and ampere/meter (A/m).

Figure 3. Here we see the 7030 gaussmeter and ZOA73-3208-05 probe ranges and resolutions in G. The gaussmeter offers 0.1 mG resolution. |

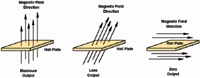

Because magnetic fields have a direction associated with them, single-axis probes aren't as user friendly when making quick measurements of the actual vector sum value. If you don't know the direction of the magnetic field, you'll need to rotate a single-axis probe until you obtain a peak reading. At that orientation, you would know that the magnetic field was directed squarely into the face of the probe's Hall effect sensor, providing an accurate measurement of the true magnetic field strength. Figure 4 shows the error associated with angular misalignment of the Hall effect device to the direction of the magnetic field. A single-axis probe is calibrated and specified with flux lines passing perpendicularly through the Hall effect sensor.

Figure 4. This diagram shows the Hall effect output with respect to magnetic field direction. Due to the uncertainty involved when using a single-axis probe and the risk associated with inaccurate test results, a 3-axis probe is the more reliable method to ensure compliance with IATA and FAA requirements. |

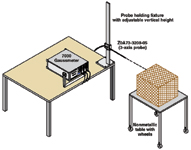

By using a 3-axis probe, you don't need to worry about the orientation of the probe with respect to the direction of the magnetic field because the system can display reliable, accurate vector sum field values. Figure 5 is a typical test setup that can be used to test the magnetic field strength of a package at different distances. The subject package should be placed on a nonmetallic table so that any magnetic field being emitted is not disrupted or shunted by the metal, resulting in inaccurate results. With the gaussmeter set to the 30 G range (providing a resolution of 0.1 mG) and set up to display the vector sum value, you will measure the magnetic field strength at the prescribed distance from all surfaces of the package. You should use a probe-holding fixture with adjustable vertical height. Since the earth's magnetic field is 0.4–0.5 G, this fixture will keep the probe in a constant position relative to the direction of the earth's magnetic field and this will enable consistent results. If you use a wheeled table, you can rotate the package around to test all four sides. Then turn the package on its side to test the top and bottom. Adjust the height of the probe to measure the magnetic field strength at varying heights. By using an array of several gaussmeters and probes, you won't need to adjust the height of a single probe and you can use a conveyer system to move packages through a sensing window.

Figure 5. This typical test setup will keep the probe in a constant position relative to the direction of the Earth s magnetic field of 0.4–0.5 G and enable consistent, reliable results. |

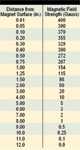

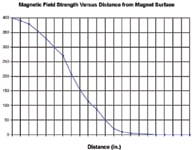

Given that the magnetic field strength reduces rapidly as the distance from the magnetic source increases, you can perform initial testing at a shorter distance from the package than the 15 ft. (CFR49) or 7 ft. (IATA) specified in the respective test requirements. For example, a strong sintered neodymium-iron-boron magnet that is 2.5 in. in diameter and 0.5 in. thick will have a magnetic field strength of ~400 G at 0.01 in. above the surface of the magnet. At 5 in. above the magnet s surface the magnetic field strength will be reduced to ~5 G. Figures 6 and 7 show the field strength of a typical sintered neodymium-iron-boron magnet at increasing distances from the magnet s surface.

Figure 6. |

If we take the magnet from the example above and change its dimensions, then for a thickness of 12 in., the magnetic field strength will be ~7400 G at 0.01 in. above the magnet's surface. At 12 in. above the surface, the magnetic field strength will be reduced to ~30 G. At a distance of 3 ft. the magnetic field level will be <1 mG. These results indicate that it would take a very large and very strong magnet or magnetized material to produce a measurable magnetic field at a distance of 7 or 15 ft. from a package s surface. However, this result in no way precludes manufacturers and shippers from complying with mandatory test requirements.

Figure 7. Measurements of the field strength of a typical sintered neodymium-iron-boron magnet at inceasing distances from the magnet s surface show that it would take a very large and very strong magnet or magnetized material to produce a measurable magnetic field at a distance of 7 or 15 ft. from a package s surface. |

Conclusion

To summarize, in order to ship magnets or magnetized materials by air, IATA and FAA regulations require manufacturers and shippers to test packages for vector sum magnetic field strengths of 2 and 5.25 mG, respectively. This measurement necessitates a gaussmeter with a resolution of 0.1 mG or better. Further, a 3-axis probe should be used to measure the vector sum magnetic field strength. If you do use a single-axis probe, either rotate the probe in space to get a peak reading or make three separate measurements, one in each X, Y, and Z plane, and then calculate the square root of the sum of the squares to find the vector sum value. Due to the uncertainty of manually rotating the probe to get a peak reading, the time consumed to make three separate measurements and calculate the vector sum value, and the risk associated with not achieving accurate test results, a 0.1 mG resolution gaussmeter with a 3-axis probe may be a more cost-effective way to ensure compliance with IATA and FAA requirements. Figure 8 summarizes the IATA and FAA test requirements and gaussmeter specifications required to achieve reliable magnetic field strength measurements.

Figure 8. This table summarizes test regulations and the measurement capabilities required if a gaussmeter is to reliably and accurately measure the magnetic field strength of packages to comply with FAA and IATA regulations. |

Jim McHan is Senior Applications Engineer, Sypris Test & Measurement, Inc. (F.W. Bell Division), Orlando, FL; 407-678-6900, [email protected], www.sypris.com or www.fwbell.com.