One of the most obvious challenges to electrical vehicle (EV) advancement and acceptance is power, or simply put, how far an EV can go on a single charge. Although state-of-the-art vehicles perform well in this area, there is great room for improvement. Enter the scientists at Fisker Inc.

Designer and manufacturer of EVs, Fisker Inc. has filed for a patent on what it calls a significant breakthrough in solid-state battery technology. The company describes its development as a flexible solid-state battery technology to challenge conventional thought on vehicle battery energy density, range, charging times and manufacturing costs. The patent includes claims over novel materials and manufacturing processes that are critical in achieving the required energy density, power and cost targets that are paramount for the widespread use of electric vehicles. A lofty description and bold claims to say the least.

The Technology

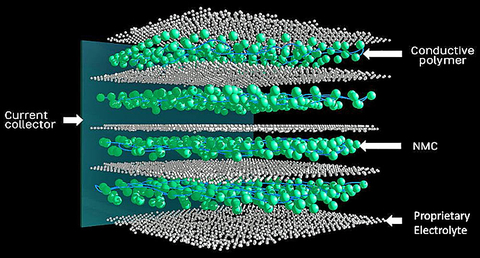

Current limitations in solid-state technology include low electrode current density, limited temperature ranges, limited materials availability, high costs, and non-scalable manufacturing processes. Initial results show that Fisker’s solid-state technology enables the construction of bulk three-dimensional solid-state electrodes with 25 times more surface area than flat thin-film solid-state electrodes and extremely high electronic and ionic conductivities, enabling fast charging and cold temperature operation. As a result, the battery delivers 2.5 times the energy density of typical lithium-ion batteries with the potential of costing one third of the 2020 projected price of those batteries due to advances in materials and manufacturing.

Several failure modes affect solid-state batteries, including low power and low rate capability due to high contact resistance and low ionic mobility in the layered electrode structures. Delamination issues due to volume changes and residual stresses during charge/discharge processes; dendrite penetration and stability vs. metallic lithium electrodes; and low ionic diffusion, particularly in low temperature climate due to solid-state material limitations, are also roadblocks. With the newly announced technology, Fisker’s scientists are addressing these technical bottlenecks.

Fisker anticipates the technology may be ready for automotive applications post 2023. Such long lead times are due to the lack of supply chains with raw materials and appropriate manufacturing tools, as well as established quality procedures for materials repeatability. Once the technology is fully validated, the battery will deliver a vehicle range of more than 500 miles on a single charge, and charging times as low as one minute – allowing technology to bypass the internal combustion engine and push the automobile into mass electrification.

Of course, time will tell and, if we are around in 2023, we’ll see if this technology bears fruit. If you need further information while you are waiting, pay a visit to Fisker Inc.