By Mike Jones, Senior Product Marketing Manager LAN Solutions Micrel Inc.

Chang-Su Mitter, Senior Product Marketing Manager, Power Management Micrel Inc.

Networking

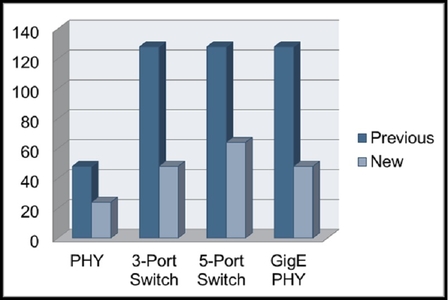

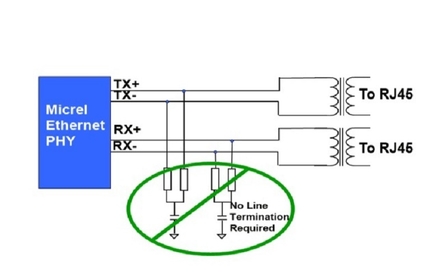

Micrel continues to set new levels in Green Ethernet technology, providing the market with increased integration, market leading package geometries and reduced BOM. The latest Ethernet device families, in addition to decreasing package sizes up to 50 percent, further reduce PCB real estate by integrating the line termination network, removing 30 passive components from the BOM on a typical 5-Port switch design, and MAC layer clock generation (see figure 1).

By combining Micrel ultra-low power patented PHY technology and reduced CMOS geometries, significant power consumption savings can be achieved, helping to alleviate thermal issues encountered by small form factor camera modules.

The new generation, KSZ8091 and KSZ9031 of Micrel Fast and Gigabit Ethernet PHY families, utilize voltage mode driver technology with integrated line termination. As a consequence overall circuit power consumption can be reduced by typically 50 percent over other competing Ethernet PHY transceivers.

PHY transceiver power consumption is a vital consideration, dominating the consumption of any Ethernet device. Typical network behavior is often one of long ‘quiet’ periods followed by relatively short bursts of traffic; take the rear view camera, for example.

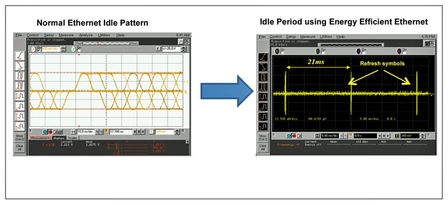

During these quiet periods, the Ethernet power consumption will not be significantly reduced. 1000Base-TX and 100Base-TX are both designed so that the link partners are continually ‘synchronized’ to each other. To enable this, when no traffic is being transmitted the PHY will automatically send out IDLE symbols (11111 5B code), as shown in figure 11 below. As a consequence, during any idle period the PHY transmitter is still operating in a manner similar to full traffic and will therefore exhibit similar power consumption.

Fig. 3: Energy Efficient Ethernet During Idle Period.

The inefficient nature of Ethernet idle power consumption has been rectified by the recently introduced IEEE 802.3az specification, known as Energy Efficient Ethernet. It is targeted to reduce power consumption during periods of low link utilization (idle time) by 50 percent or more, drastically improving Ethernet power efficiency. This technique, known as Low Power

Idle (LPI), will disable parts of the PHY transceiver that are not necessary, whilst still maintaining the link integrity. When new frames arrive, the PHY is awoken and the returns to the normal active state. During LPI, a periodic refresh symbol is sent out by the PHY to ensure that the receiver is synchronized. An example of IEEE 802.3az Energy Efficient Ethernet operation is shown in figure 3 above.

The new KSZ9031 Gigabit PHY transceiver family offers in addition to industry leading power consumption during normal operation of sub 450mW, a mere 50mW dissipation during idle mode, when EEE is enabled. This equates to a saving of nearly 90 percent power consumption, enabling Ethernet to now truly become ‘Green’. IEEE802.3az Energy Efficient Ethernet is supported in all the latest Micrel Ethernet product families.

- KSZ8091 – 10/100Base-TX Ethernet PHY

- KSZ9031 – 10/100/1000Fase-T Ethernet PHY

- KSZ8463 – 10/100Base-TX/FX 3-Port Ethernet Switch, with IEEE1588v2 / IEEE 802.1AS

- KSZ8462 – 10/100Base-TX/FX 2-Port Ethernet Controller, with IEEE1588v2/ IEEE 802.1AS

- KSZ8441 – 10/100Base-TX/FX Single-Port Ethernet Controller, with IEEE1588v2/ IEEE 802.1AS

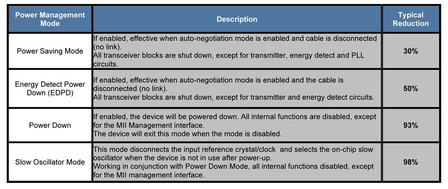

During ‘standby’ operation there are five fully configurable advanced Power Management modes of operation (below), supported by all Micrel latest Ethernet product families. In addition, Micrel provides full integrated Wake-on-LAN (WoL) support in their latest Fast Ethernet and Gigabit Ethernet PHY families, KSZ8091 and KSZ9031, respectively. WoL is designed to ‘wake up’ the system during a low power idle state and will be typically controlled by the Ethernet network interface (PHY/MAC).

Micrel Ethernet product families include the largest variety of AEC-Q100 qualified automotive Ethernet devices on the market. Industry-leading ESD and EMI performance, in addition to AEC-Q100 Automotive and Industrial grade solutions with operating temperature ranges up to 125°C. The latest 10/100Base-TX KSZ8091 PHY provides a HBM (Human Body Model) ESD rating of >±7 kV. The evaluation board has also been shown to provide > 9 kV contact and >16.5 kV air ESD ratings, without the need for any external over voltage protection devices. This surpasses typical OEM automotive vendor Electromagnetic Compatibility (EMC) requirements.

Automotive and Industrial Grade Ethernet leadership continues and the introduction of Quiet-WIRE technology. Quiet-WIRE technology significantly reduces the PHY radiated emissions enabling the use of low-cost cabling and connector harness, previously only achievable with shielded or fibre connectivity, a key factor when implementing automotive multi-camera systems.

In addition to reducing cable costs, lower noise levels improve signal integrity and image performance, critical in space limited camera applications. Quiet-WIRE featured Ethernet PHYs are fully adjustable to meet necessary cable type, length and emissions limits and interoperable with any standard Ethernet PHY.

Standard Ethernet interoperability, opposed to more proprietary means, is vital for utilization across any Ethernet application where stringent EMC may apply, such as automotive in-car connectivity and industrial control. For Ethernet to provide the necessary quality of service (QoS) for real time applications, including video streaming of camera networks, the recent IEEE Audio Video Bridging (AVB) specifications need to be considered to ensure a desired deterministic behavior.

The key addition to the Ethernet capabilities is Time Synchronization, as defined in the IEEE 802.1AS specification, to deliver the necessary image quality. IEEE 802.1AS ensures that each node in the network can operate from a local real-time clock that is synchronized to within 1 µs, in both time and frequency to a selected master clock source.

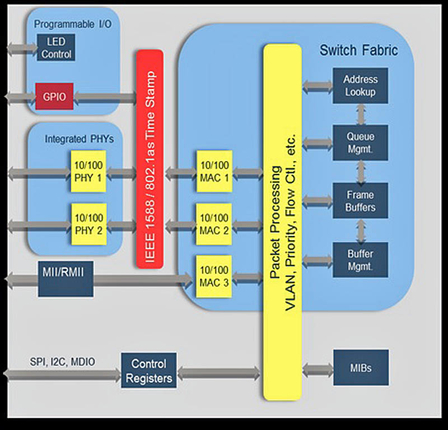

The aforementioned newly introduced KSZ84xx family, Figure 12, from Micrel supports IEEE 802.1as EtherSynch technology. Timing accuracy in the order of sub 100 ns can be achieved; outperforming the IEEE-based standard (1 µs) by a factor of 10. All devices feature embedded ultra-low power PHY transceivers, IEEE 802.3az EEE support, time precision GPIO in a compact 10mm x 10mm 64-LQFP package (see figure 5).

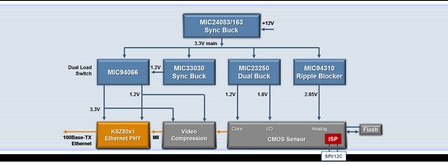

The block diagram of figure 6 illustrates a typical power management solution for an IP camera application. First stage power conversion generates a 3.3V rail from the 12V input, which supplies I/O power and input voltage for downstream converters.

The CMOS sensor analog input is supplied by the MIC94310 ripple blocker LDO, which regulates and filters the supply voltage for the analog circuitry. The ripple blocker lowers cost and reduces size by eliminating the need for secondary filters. The Core and I/O supply voltages are provided by the MIC23250 dual buck converter.

The MIC33030 high-efficiency synchronous buck regulates the 1.2V rail. This rail and the 3.3V supply are distributed and controlled by the MIC94066 dual load switch, which controls sequencing to the PHY and Video circuitry.

In the data signal path, the front-end a sensor, will capture the image array. Image signal processing is provide for exposure control, white balance, gamma correction, defective pixel and cancelling, before converting the image into a YUV (Y=Luma component, UV=Chrominance component) 8-bit /or 10-bit parallel output format. YUV format encodes a color image taking human perception into account. This provides reduced bandwidth for the chrominance components by allowing any compression artifacts to be more efficiently masked by the human perception than using a direct RGB.

Further compression ready for transmission is provided by the video compression processor, typically H.264/MPEG 4 or Motion JPEG. Such formats allow the image data to be encapsulated into an Ethernet frame for streaming over the Ethernet PHY transceiver.

The demand and need for higher performance smart IP-camera continues to grow. More and more, consumers rely on networked cameras to see for us − when they drive, to manage property when owners are there and keep it safe when they aren’t, and for entertainment. Networked camera solutions need to be engineered for energy efficiency, low noise and size, high quality, and cost effectiveness − and this is where Micrel is focused (see figure 7). By integrating analog, mixed signal and digital capabilities, Micrel delivers high-value solutions to customers around the world.